Electric valve

A technology of electric valve and valve shaft, applied in the direction of lift valve, valve device, valve details, etc., can solve problems such as unsolved problems, and achieve the effects of preventing incoordination, improving lubricity, and reducing sliding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

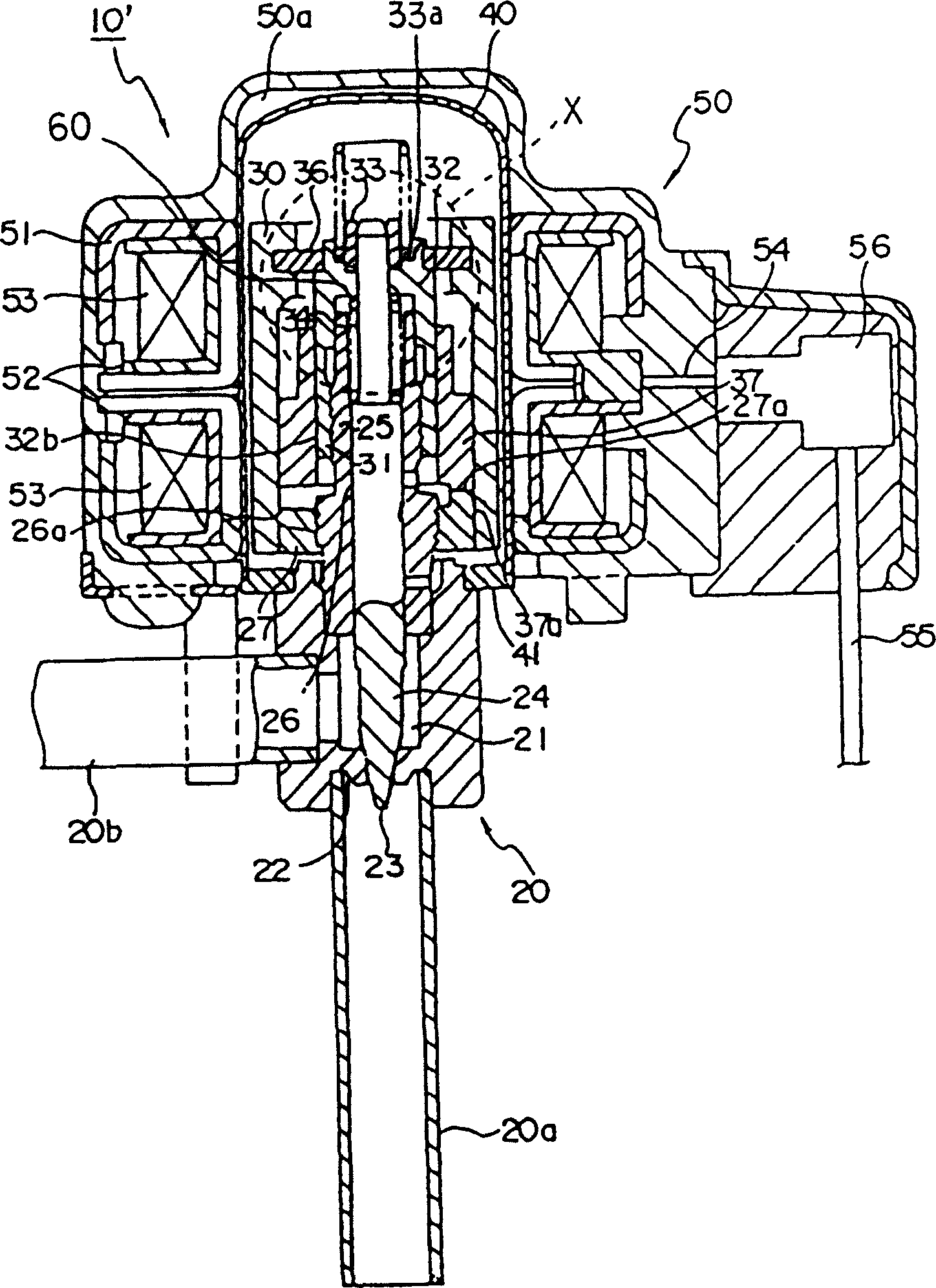

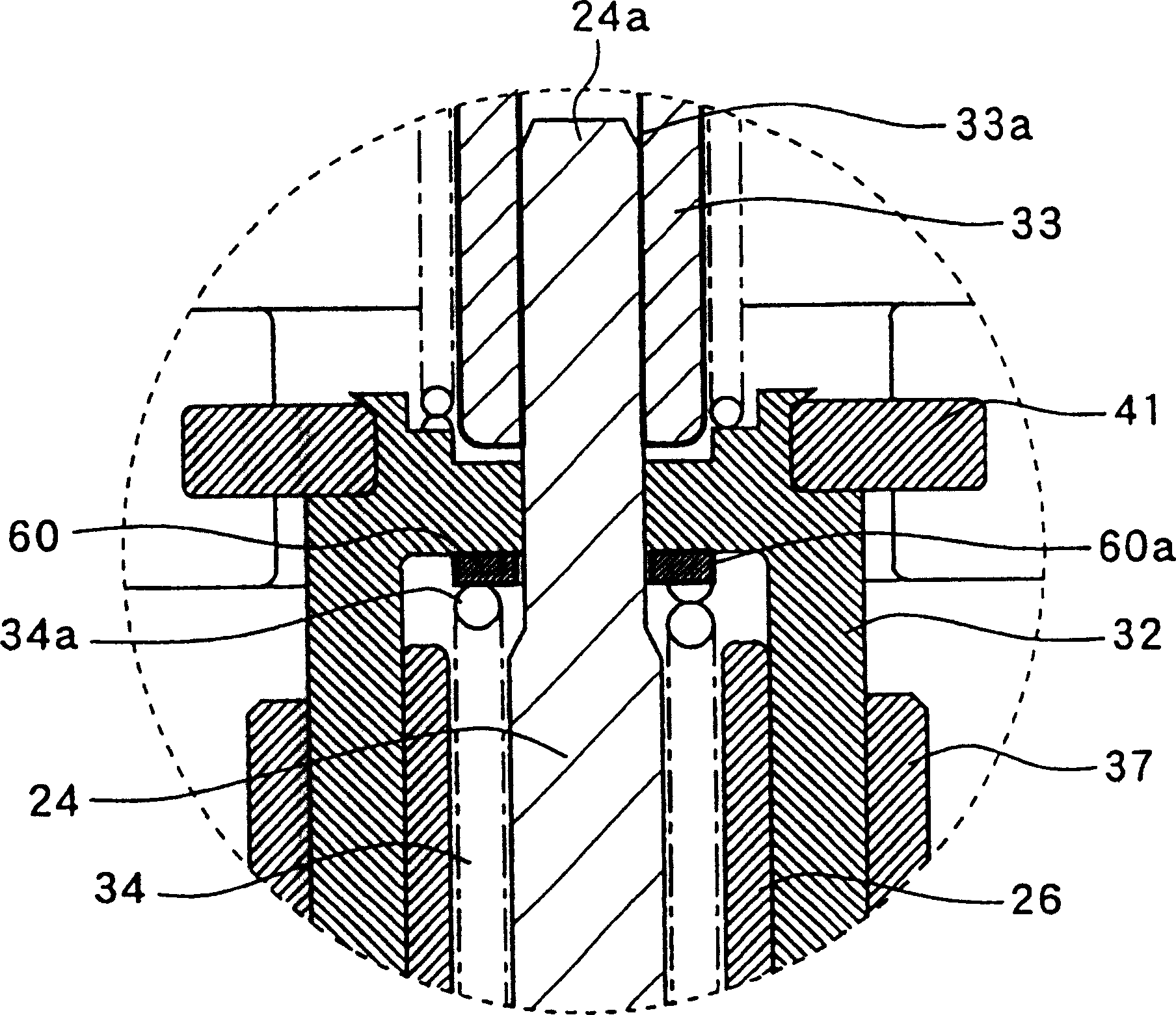

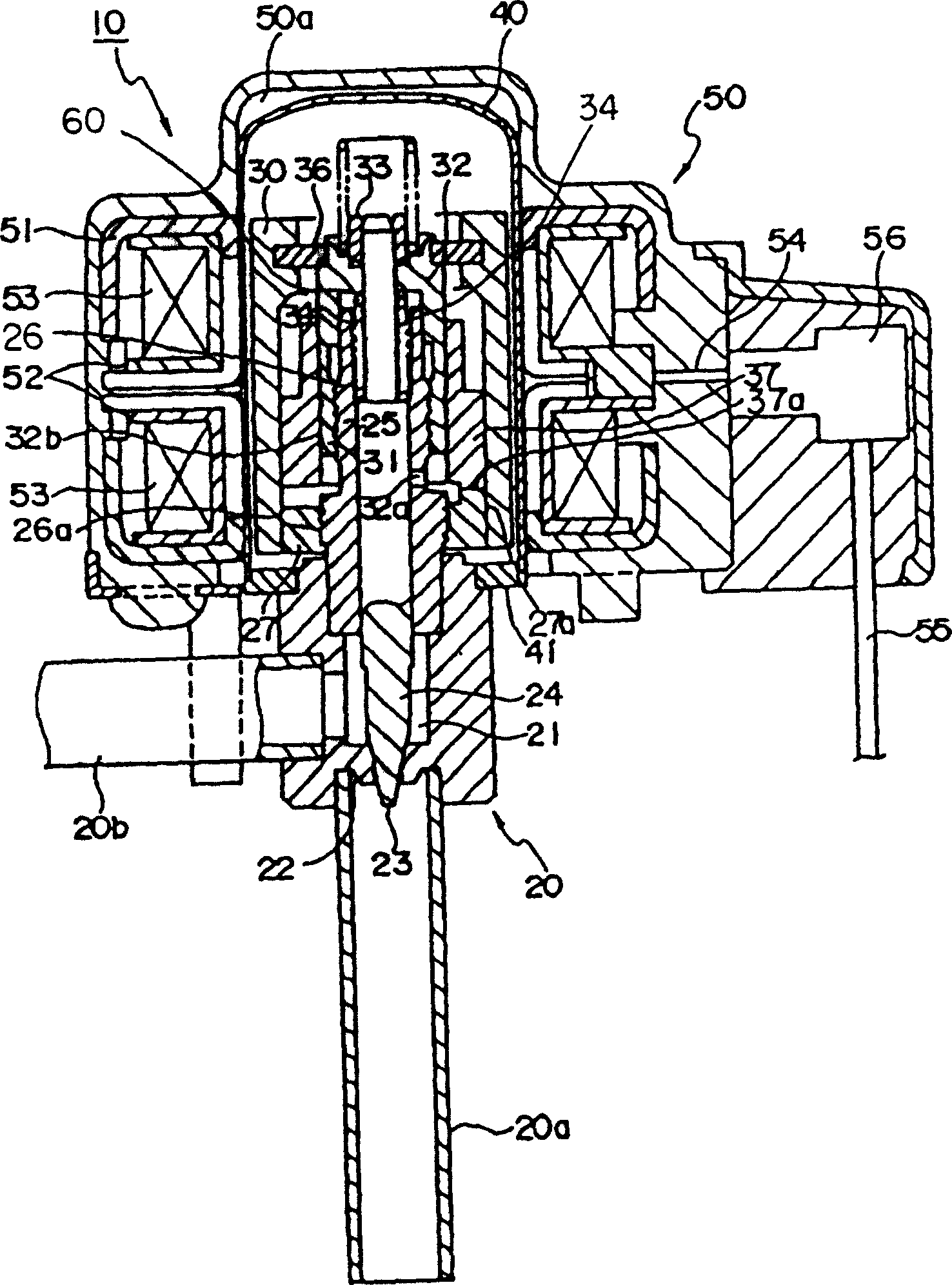

[0025] figure 1 It is a longitudinal sectional view of an embodiment of the electric valve 10' of the present invention, figure 2 yes figure 1 Enlarged view of part X of , based on these figures to illustrate. Below, in the description of the embodiments of the present invention, for figure 1 , 2 in and image 3 Components that are the same as those of the electric valve 10 in the shown known example are given the same reference numerals, and description thereof will be omitted.

[0026] As a feature of this embodiment, the surface of the thrust nut 33 is plated with nickel (Ni), or the surface is coated with nickel (Ni) plated metal including polytetrafluoroethylene (PTFE) as the plated layer 33 a. In addition, the metal plated layer 60a made of the same material as the surface of the thrust nut 33 is formed on the surface of the flat metal sheet 60 as well. Moreover, these treatments (the formation of the metallized layers 33a, 60a) can be carried out on the entire s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com