Capacitance detector, method of detecting capacitance, and fingerprint sensor

A capacitance detection and sensor technology, which is applied in the direction of converting sensor output, using electromagnetic/magnetic devices to transmit sensing components, electromagnetic measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

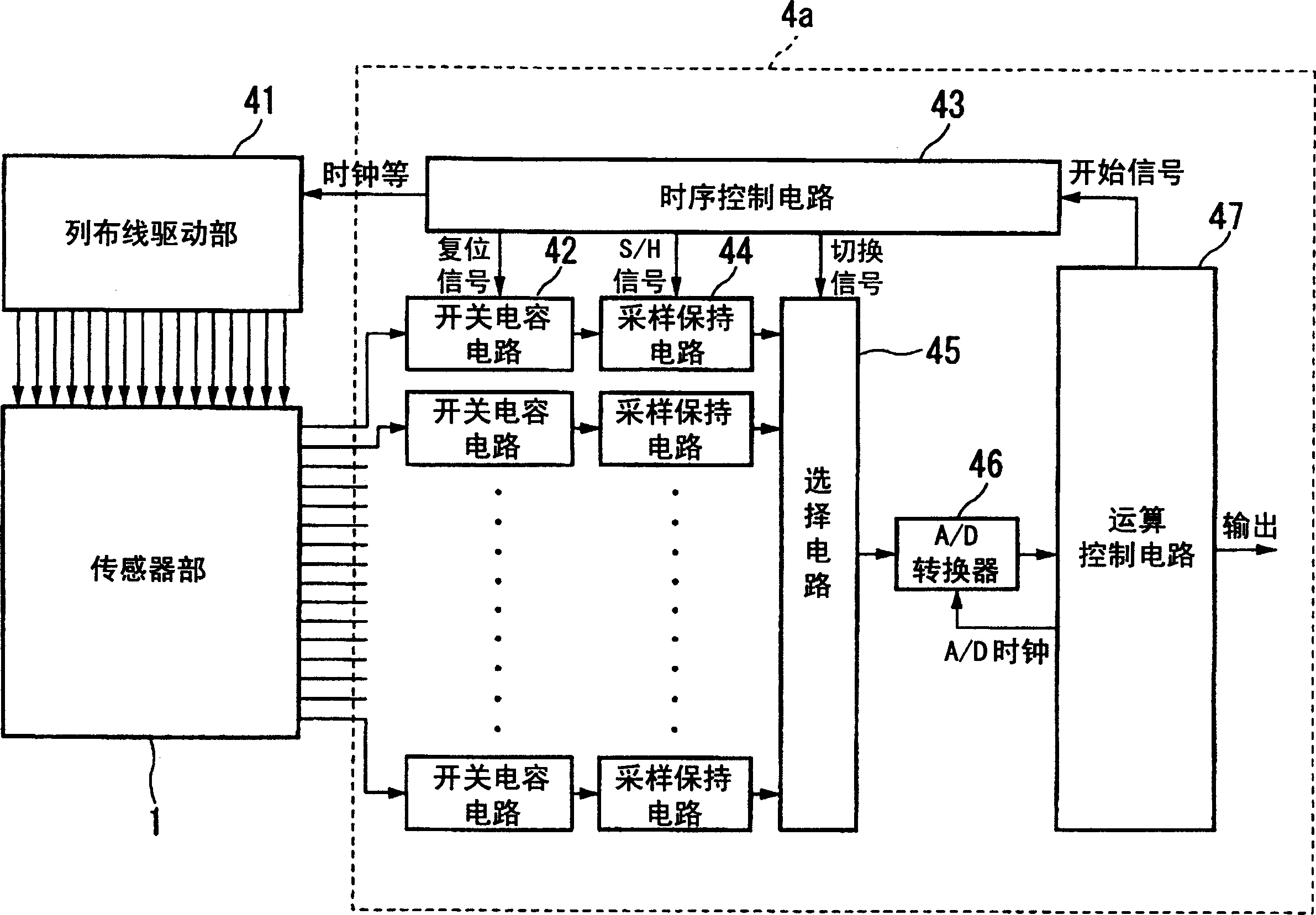

[0034] figure 1 It is a block diagram of the overall configuration of the first embodiment of the present invention. In the figure, a column wiring driving unit 41 (column wiring driving means) sequentially outputs signals that rise and fall with respect to a specific potential to each of the column wirings of the sensor unit 1 . When there is no output signal, it is kept at ground potential. Output signals from the wiring lines of each row of the sensor unit 1 are input to the capacitance detection circuit 4a.

[0035] The capacitance detection circuit 4a receives the output signal of the sensor unit 1, and detects the capacitance at each intersection of the column wiring and the row wiring. The internal function of the capacitance detection circuit 4a will be described below. Switched capacitor circuits 42, 42, . . . are connected to each row wiring. The switched capacitor circuits 42, 42, . The sampling memory circuits 44 , 44 . . . hold the output signals of the swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com