Ultra-low flying height slider and design method thereof

A technology of floating height and slider, which is applied in the direction of instruments, calculations, computers, etc., and can solve problems such as slider head and/or magnetic recording disk damage, head/disk contact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

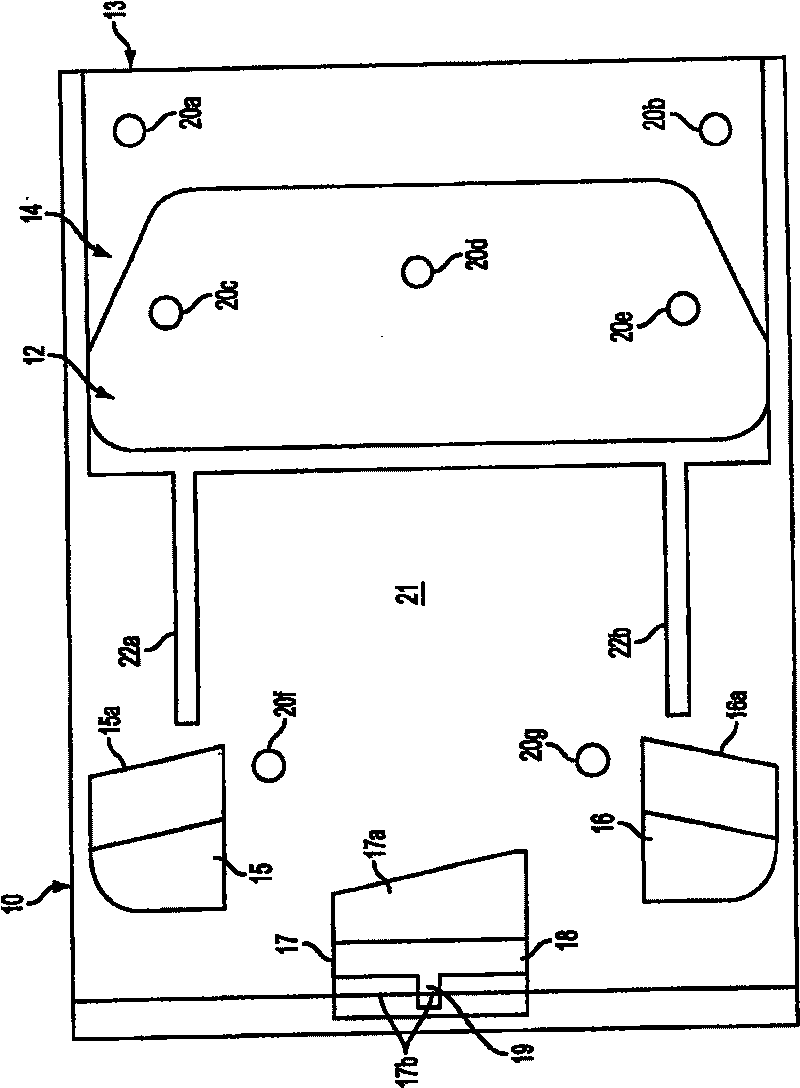

[0021] image 3 is a bottom plan view of the slider 10 for a low pressure slider according to an embodiment of the present invention. To illustrate specific features of ABS described below, it should be understood that the entire slider body, not shown, may be made of a base material such as Al 2 o 3 TiC composition. exist image 3 The slider 10 shown in includes a front air bearing surface 12 . The air bearing surface is marked off from the leading edge 13 of the slider 10 by a front step 14 . In this particular embodiment, the front step 14 has a depth relative to the front air bearing surface. In this particular embodiment, the depth is between 2 and 10 microinches. Double-sided air bearing surfaces 15 , 16 are provided at the inner and outer edges of the slider 10 . Although these two surfaces are provided, the invention is not limited to this number. Each of the air bearing surfaces 15, 16 comprises a secondary structure 15a, 16b respectively at a lower level. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com