Horn switch gear and airbag system

A switch device and speaker technology, applied in the direction of electric switch, signal device, sound signal device, etc., can solve the problem of high difficulty in assembly operation, and achieve the effect of good assembly operability and easy determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

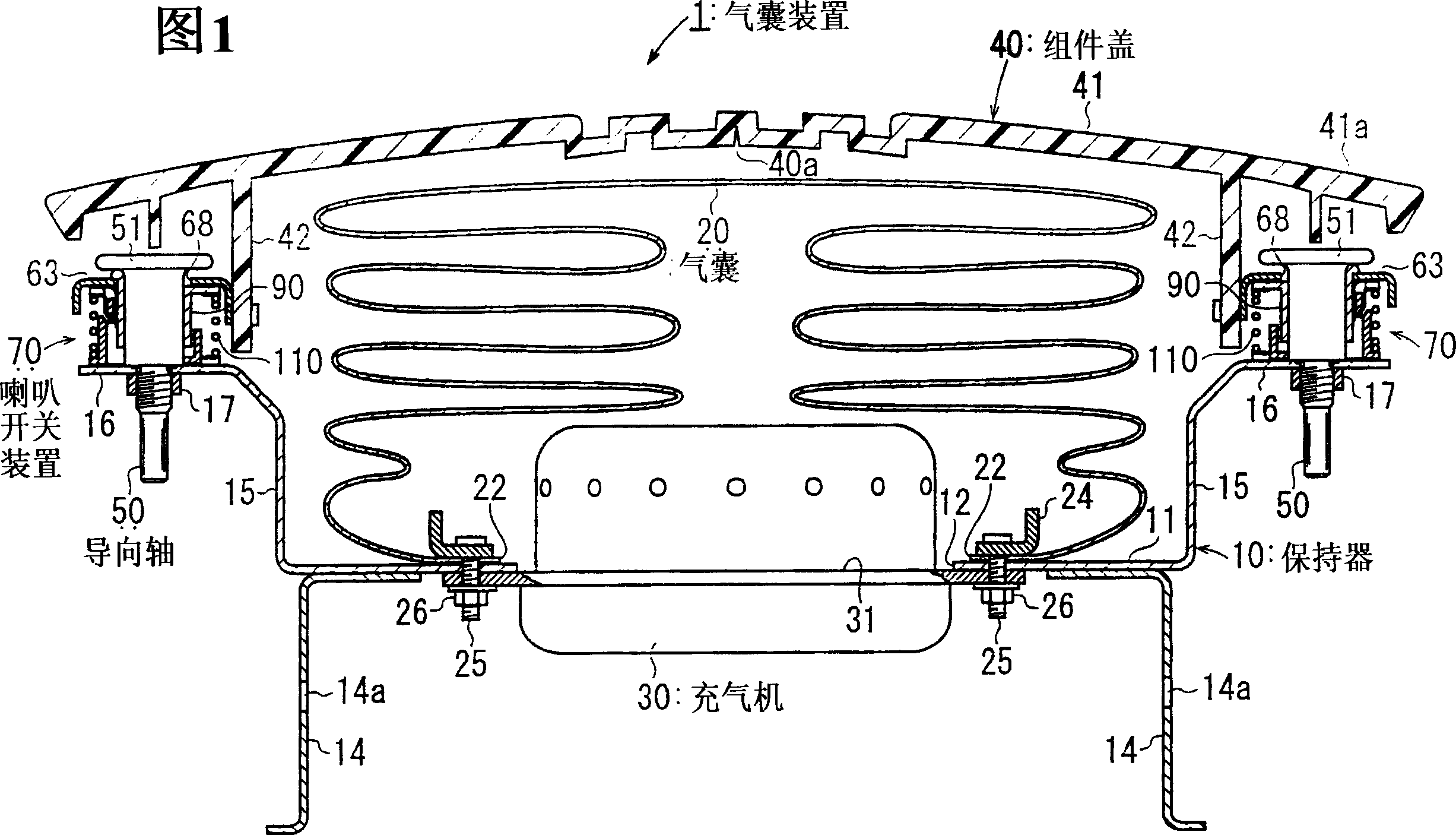

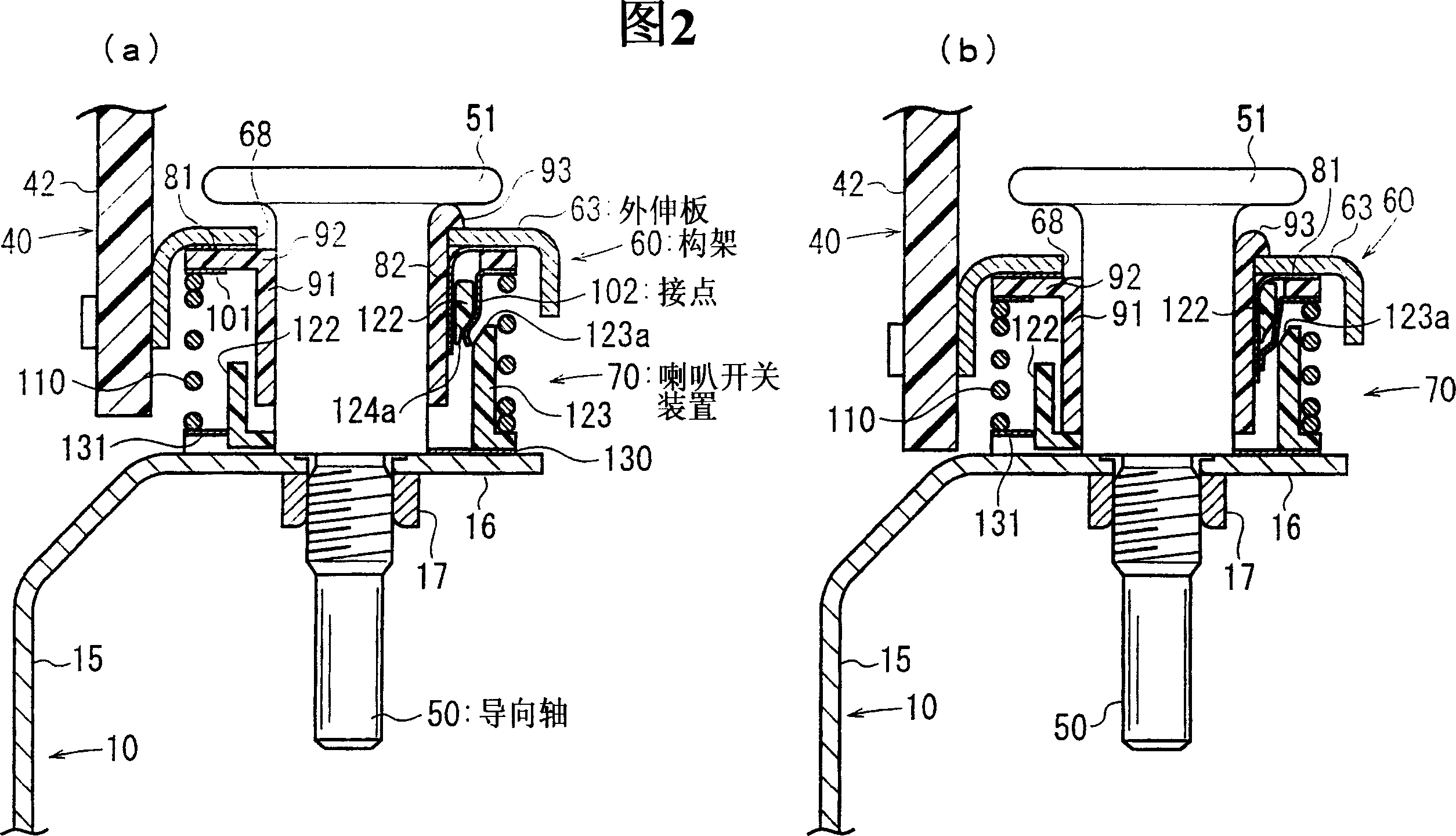

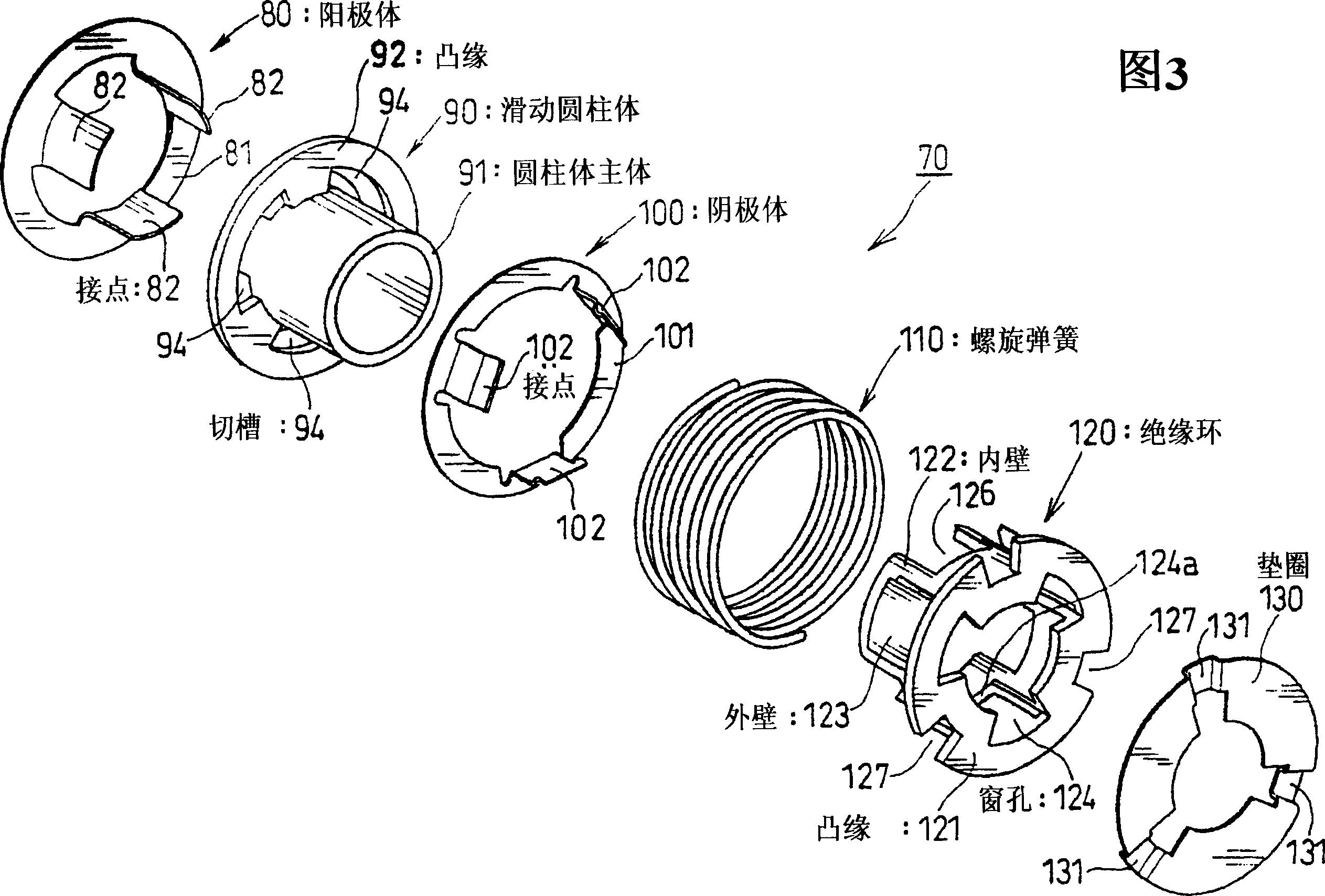

[0041] Embodiments are described below with reference to the drawings. FIG. 1 is a cross-sectional view of an airbag device provided with a horn switch device in an embodiment. Fig. 2(a), (b) are partial enlarged views of the horn switch in Fig. 1 . Fig. 3, 4 is the disassembled view of this horn switch device, and Fig. 3, 4 is the situation that mutually sees from the opposite direction. Fig. 5 is an exploded perspective view of the airbag device. In addition, FIG. 2(a) shows the "unpressed" state where the assembly cover 40 is not pressed, and Fig. 2(b) shows the "pressed assembly cover state" in which the horn sounds after the assembly cover 40 is pressed.

[0042] The airbag device 1 is an airbag device for a driver's seat provided in the center of a steering wheel. The structure of this airbag device 1 is provided with a retainer 10 made of metal, an airbag 20 mounted on this retainer 10 with an airbag mounting ring 24, an inflator 30 for inflating the airbag 20, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com