Coke automatic sample collecting and making method

A technology of sample collection and coke, which is applied in the direction of sampling device, test sample preparation, etc., can solve the problems of inability to guarantee the quality of sample collection, poor representativeness of sample collection, poor operating environment, etc., achieve mechanized and automatic operation, and eliminate artificial Factors influencing, enhancing the effect of representativeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

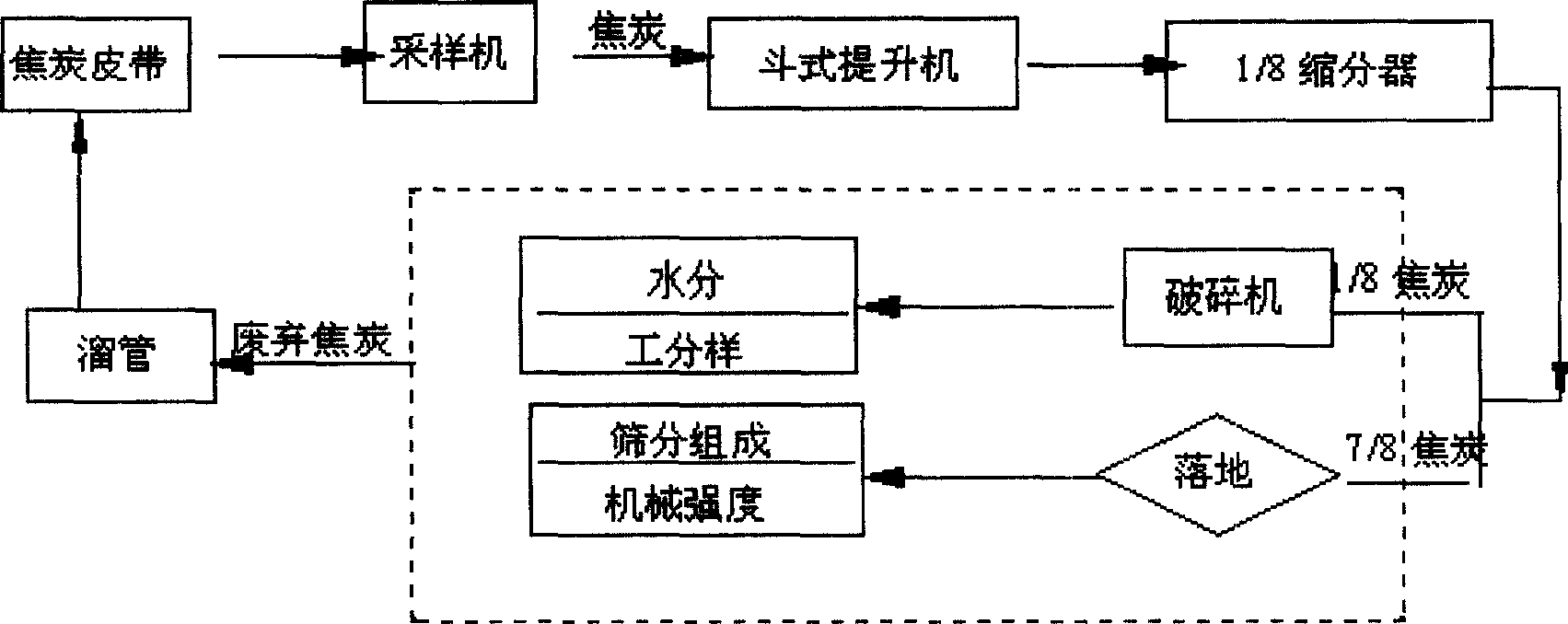

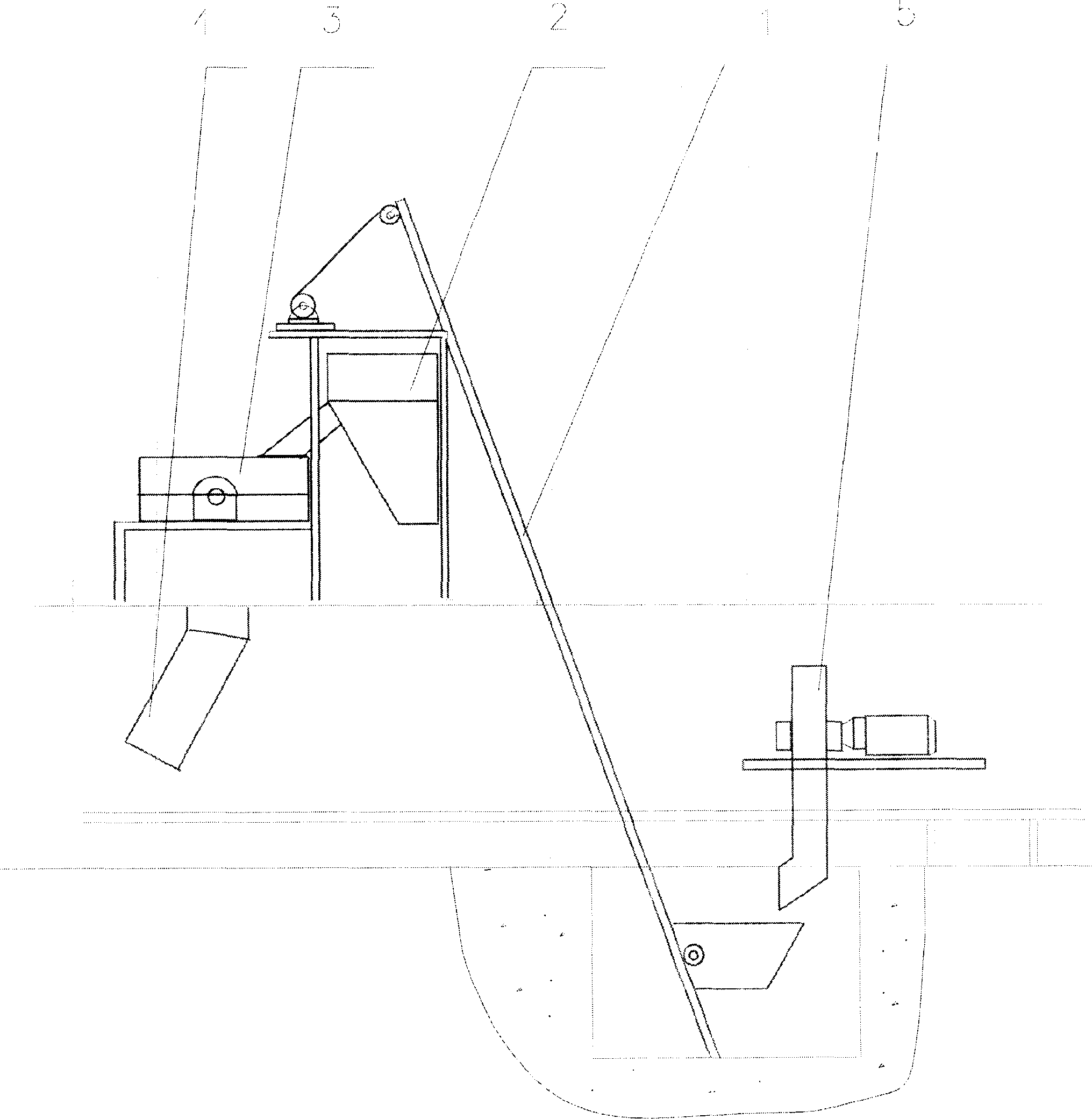

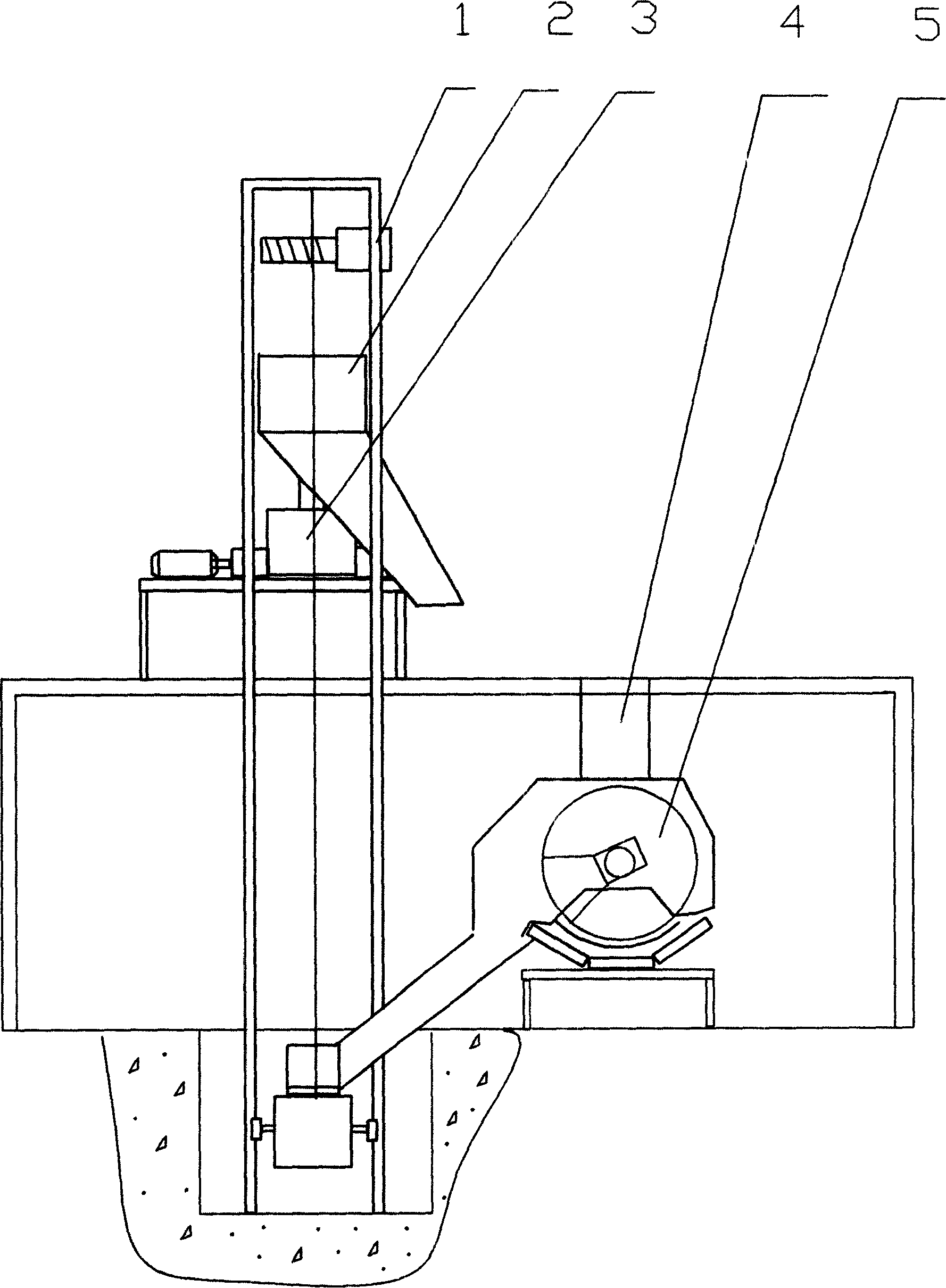

[0048] The present invention will be further described below with reference to the drawings and embodiments: a two-story building is built on the belt corridor, the sampling machine 5 is installed on the first floor, and the sampling machine 5 is directly welded and installed on the foundation of the belt frame for transporting coke. The sampling machine 5 adopts a sub The sample volume is 15kg. After taking the material twice, it is lifted from the hoist 1 to the second floor of the corridor and enters the 1 / 8 reduction divider 2 for reduction, and the 1 / 8 coke enters the ring hammer crusher 3 for crushing to prepare water and work points In this way, 7 / 8 coke was dropped to the ground for screening composition and mechanical strength tests. The waste coke is returned to the coke transport belt from the second floor through the chute 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com