Tool receptacle, in particular a quick-change clamping chuck and its protecting device

A protective device and replaceable technology, which is applied in the direction of chucks, portable motorized devices, maintenance and safety accessories, etc., can solve the problem of damaged parts, etc., and achieve the effect of easy installation or disassembly, simple and economical installation or disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

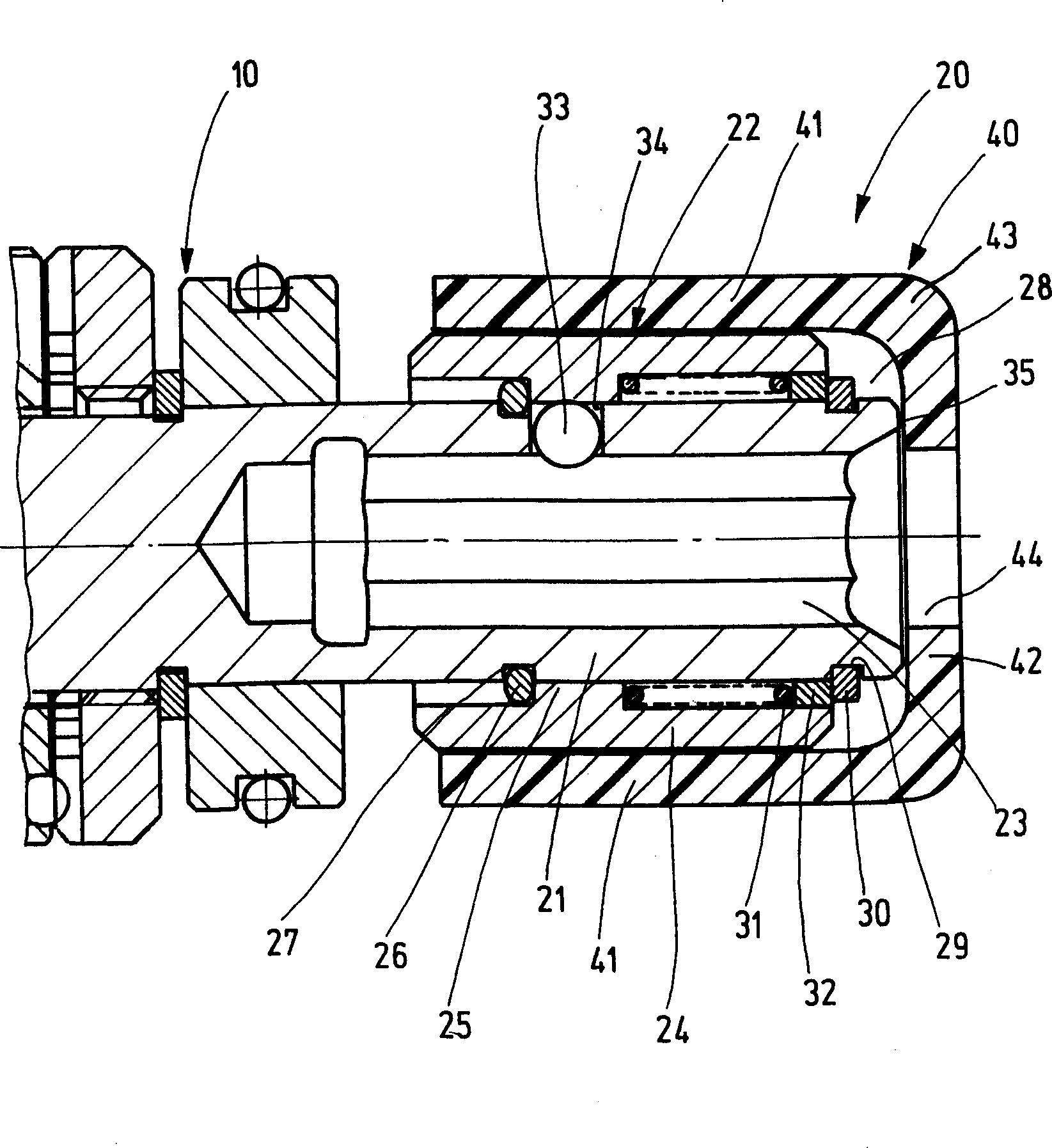

[0015] In the drawing, the end of a portable power-driven machine tool 10 is shown schematically, which consists of a screwdriver, drill or similar machine tool and is Driven by a drive motor and a rear-mounted, also not shown, transmission. The portable power tool 10 has at its end an axially arranged tool holder 20 , in particular in the form of a quick-change chuck, as shown. The tool holder 20 has a holding sleeve 21 with a locking device 22 for releasably locking a tool, not shown, which can be accommodated in the holding sleeve 21 . The tool is to be received by its shaft in an axially inner receiving cavity 23 of the holding sleeve 21 , for example having a polygonal profile, for example a hexagonal profile, adapted to the corresponding cross-sectional shape of the tool shaft. The locking device 22 has a locking sleeve 24 which overlaps the holding sleeve 21 and is axially displaceable and fixed on the holding sleeve. An O-ring 26 on the left side of a radially inward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com