Method for regulating the power supply of a number of field devices

A field device, stable technology, applied in the field of stabilizing the power supply of multiple field devices, can solve the problems of expensive, low consumption value of independent field devices, low measurement rate of independent field devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

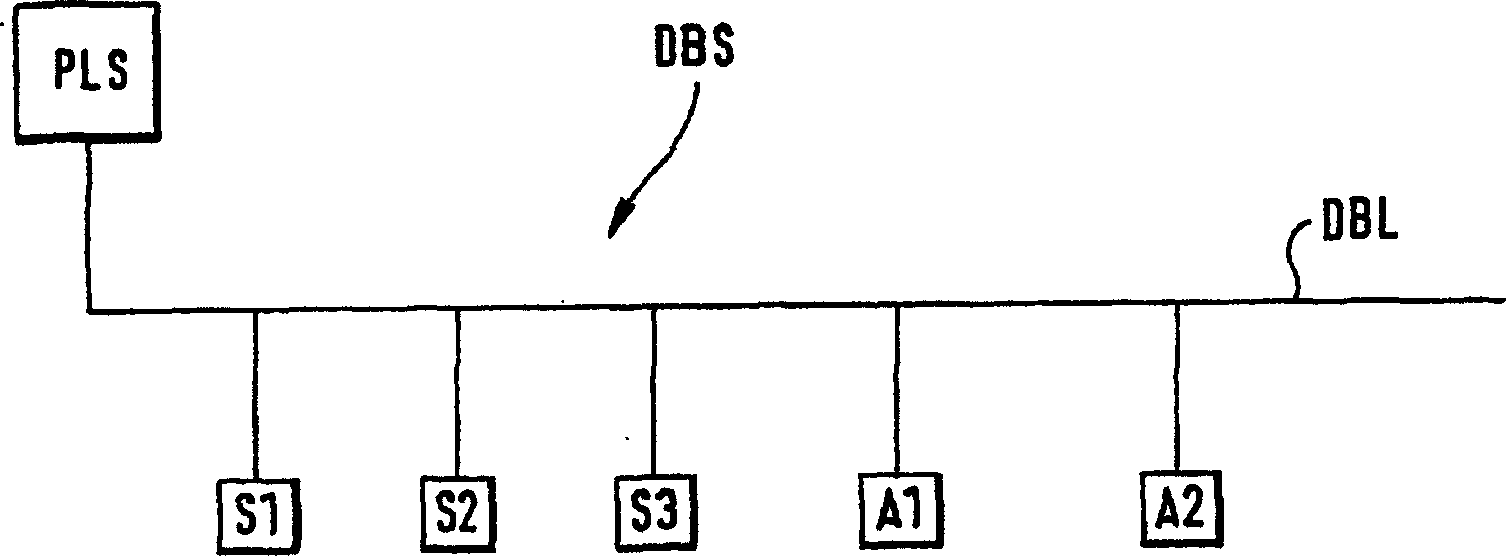

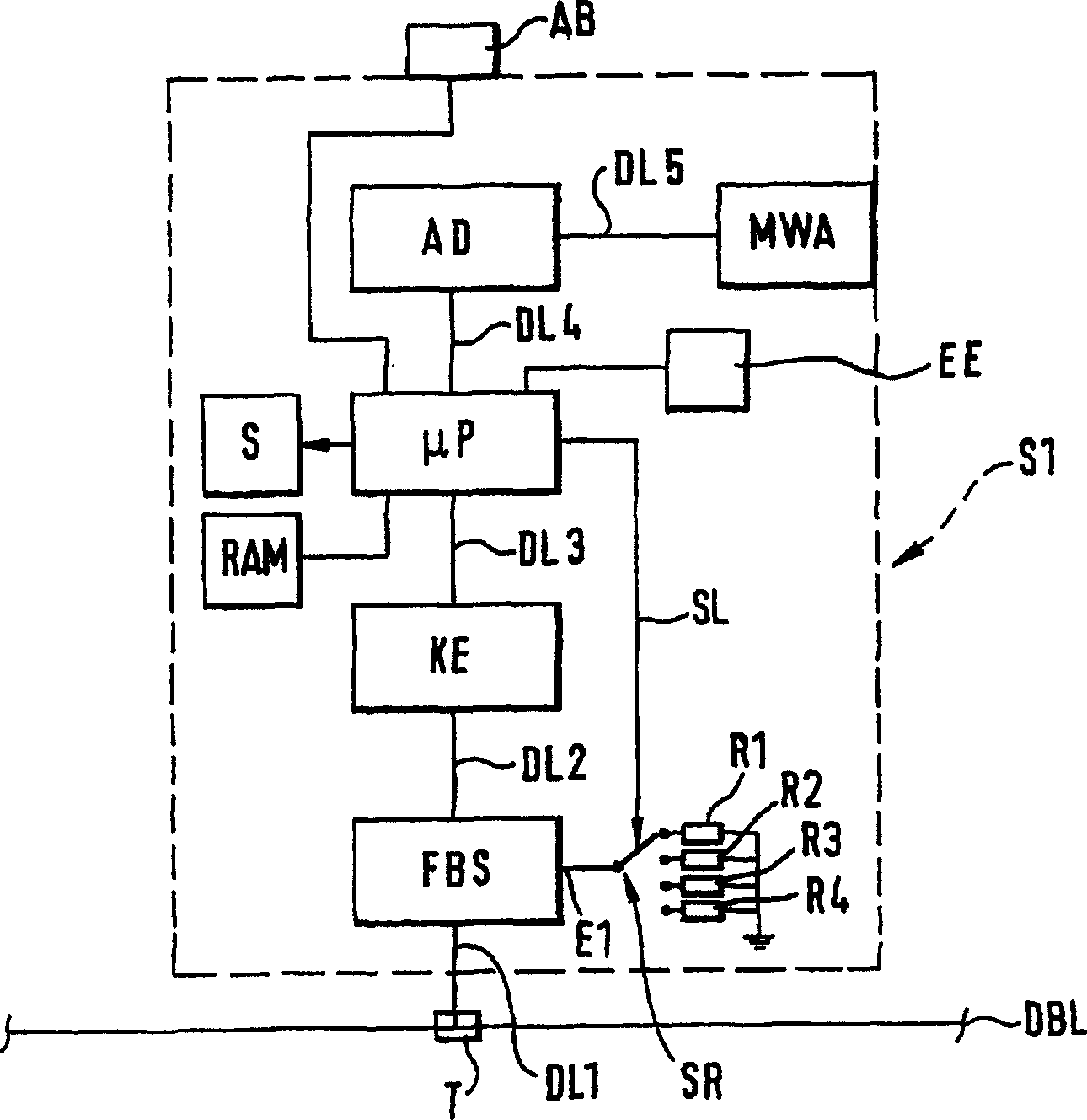

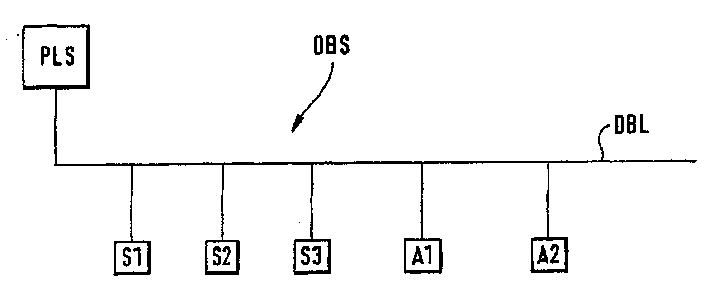

[0022] figure 1 A data bus system DBS comprising a plurality of field devices and a process control system PLS is shown. Field devices include sensors S and actuators A. The data bus participants are connected to the field bus DBL. The process control system PLS is usually placed in a control room from which the entire process control takes place centrally. Sensor S and actuator A are placed "in situ" at separate process elements (tanks, feeding equipment, pipelines, etc.). Sensors S1 , S2 and S3 detect eg process variables temperature T, pressure P and flow F at a specific process element in each case. Actuators A1 and A2 are, for example, valve controllers that stabilize the flow of liquid or gas through a length of pipeline. Data transfer between process control system PLS, sensor S and actuator A in a known manner using special protocols (e.g. PROFIBUS or FOUNDATIONFIELDBUS, CAN-Bus) according to international standard transmission technologies (e.g. RS 485 or IEC1158)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com