Preparation method of activated carbon loaded nano zero-valent iron composite material

A nano-zero-valent iron and composite material technology, applied in the field of material preparation, can solve problems such as high cost, uneven particle size distribution, and easy agglomeration, and achieve low cost, good dispersion performance and oxidation resistance, and simple equipment requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

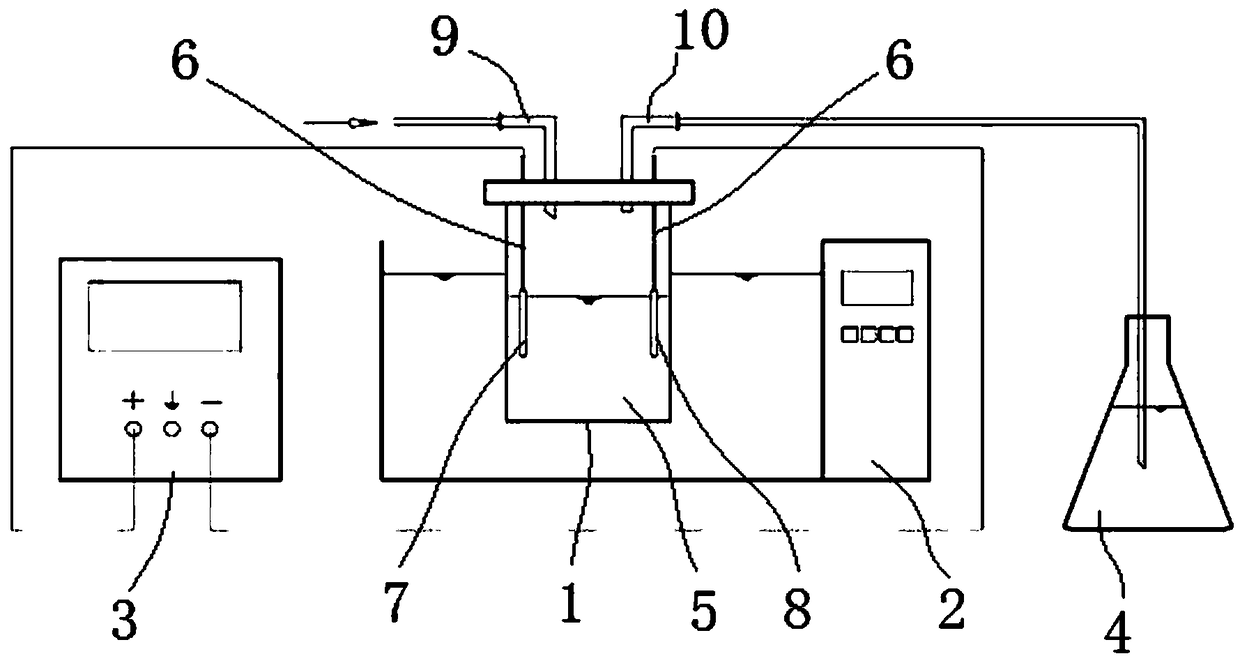

Method used

Image

Examples

Embodiment 1

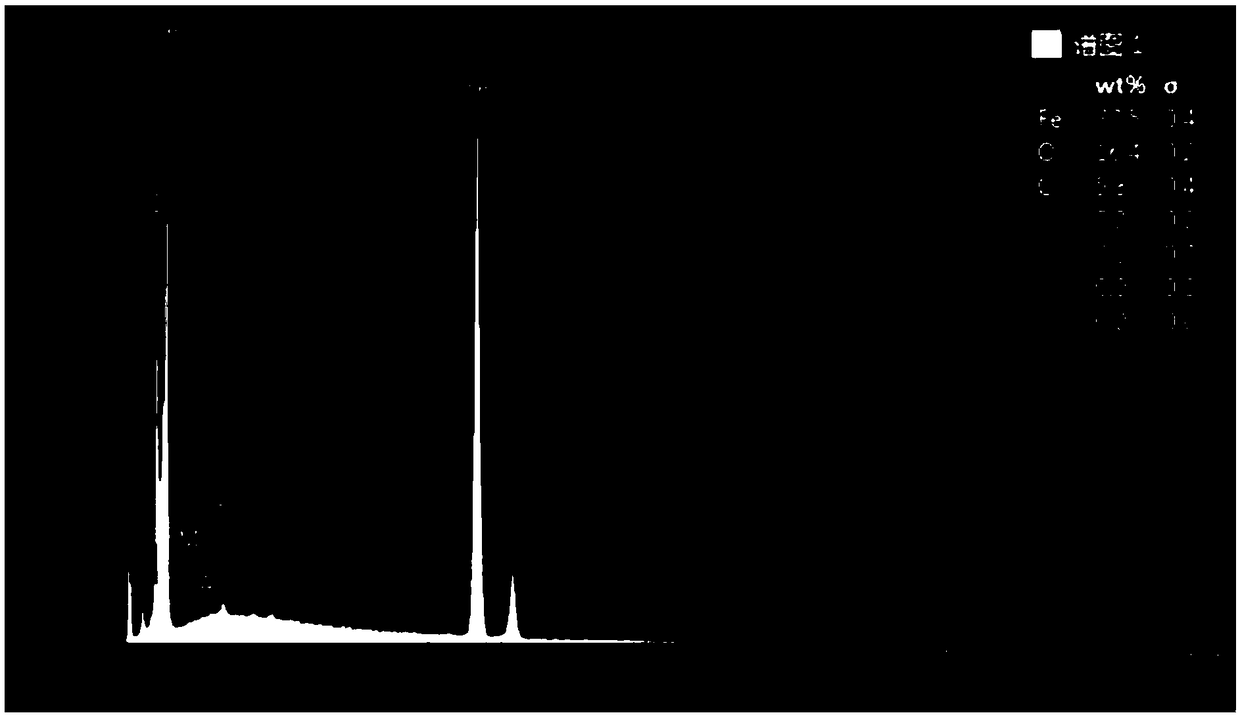

[0030] Embodiment one, a kind of preparation method of activated carbon loaded nanometer zero-valent iron composite material, it comprises the following steps:

[0031] Step 1, mix activated carbon, graphite and polytetrafluoroethylene emulsion according to the mass ratio of 8:1:1, use absolute ethanol as the dispersant, take out the mixed slurry after ball milling for 6 hours, the ball milling speed is 120 rpm, and the mixed slurry After the material is gradually converted from a viscous state to a semi-dry state, it is rolled into an activated carbon film with a thickness of 0.35mm on a double-roller machine, and then from top to bottom in the order of activated carbon film, conductive layer, and activated carbon film. The conductive layer is Nickel foam, with a thickness of 0.5mm, is rolled on a double-roller machine several times, boiled in ultrapure water for 30 minutes, vacuum-dried at 60°C for 2 hours, and cut into activated carbon electrode sheets of 40mm×40mm;

[0032...

Embodiment 2

[0036] Embodiment two, a kind of preparation method of activated carbon loaded nanometer zero-valent iron composite material, it comprises the following steps:

[0037] Step 1, mix activated carbon, graphite and polytetrafluoroethylene emulsion according to the mass ratio of 8:1:1, use absolute ethanol as the dispersant, take out the mixed slurry after ball milling for 4 hours, the ball milling speed is 100 rpm, and the mixed slurry After the material is gradually converted from a viscous state to a semi-dry state, it is rolled into an activated carbon film with a thickness of 0.40mm on a double-roller machine, and then from top to bottom in the order of activated carbon film, conductive layer, and activated carbon film. The conductive layer is Nickel foam, with a thickness of 0.7mm, is rolled on a double-roller machine several times, boiled in ultra-pure water for 35 minutes, vacuum-dried at 65°C for 2.5 hours, and cut into activated carbon electrode sheets of 32mm×32mm;

[0...

Embodiment 3

[0041] Embodiment three, a preparation method of activated carbon-loaded nano-zero-valent iron composite material, which comprises the following steps:

[0042] Step 1, mix activated carbon, graphite and polytetrafluoroethylene emulsion according to the mass ratio of 8:1:1, use absolute ethanol as the dispersant, take out the mixed slurry after ball milling for 6 hours, the ball milling speed is 150 rpm, and the mixed slurry After the material is gradually converted from a viscous state to a semi-dry state, it is rolled into an activated carbon film with a thickness of 0.40mm on a double-roller machine, and then from top to bottom in the order of activated carbon film, conductive layer, and activated carbon film. The conductive layer is Nickel foam, with a thickness of 1.0mm, is rolled on a double-roller machine several times, boiled in ultrapure water for 40 minutes, vacuum-dried at a temperature of 63°C for 3 hours, and cut into activated carbon electrode sheets of 48mm×48mm;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com