Jet nozzle for textile machine and its cleaning method

A processing machine and nozzle technology, applied in the direction of spraying/jetting textile material treatment, spraying devices, etc., can solve problems such as nozzle clogging, achieve the effects of no clogging and reduced dyeing liquid volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

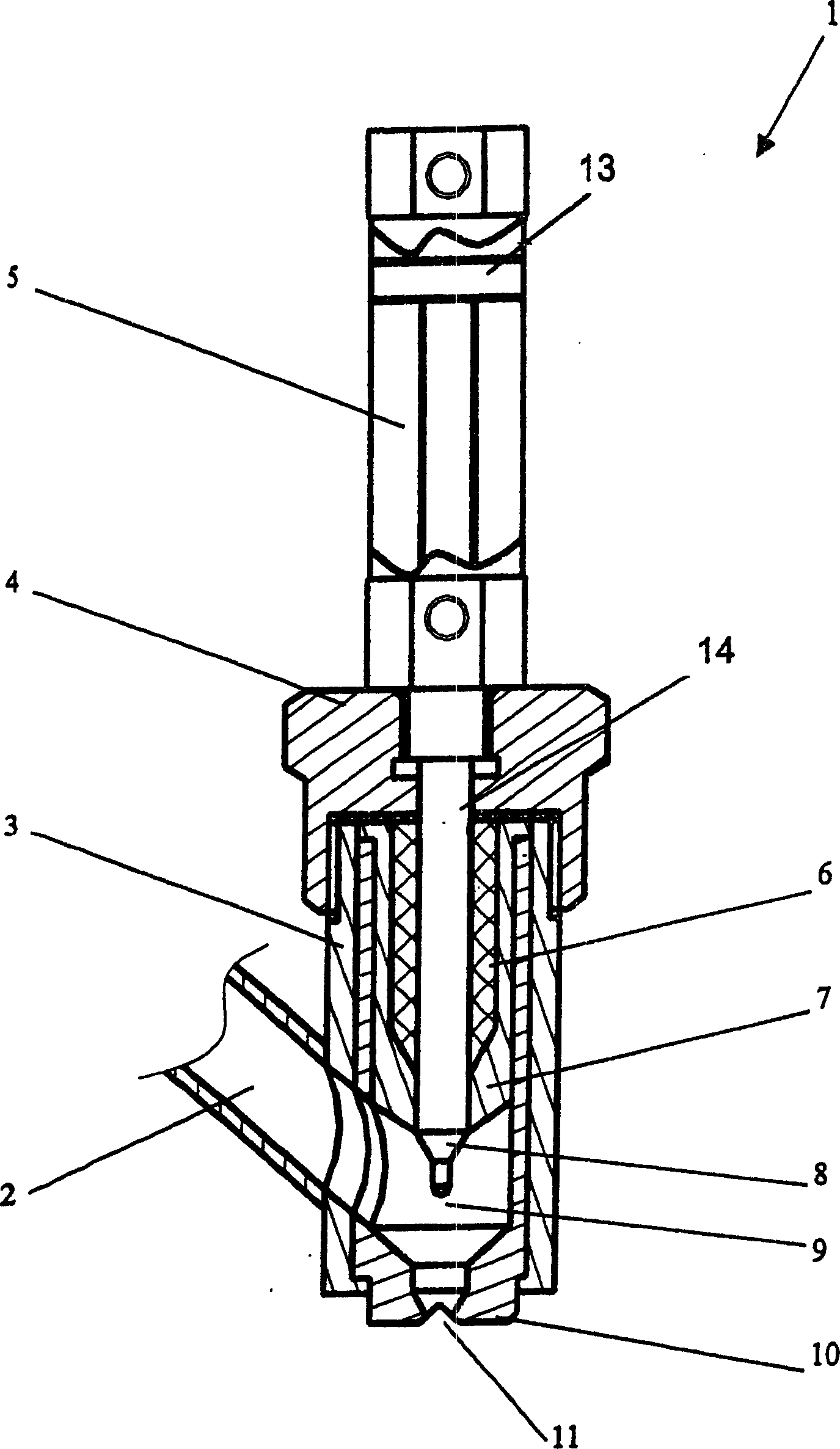

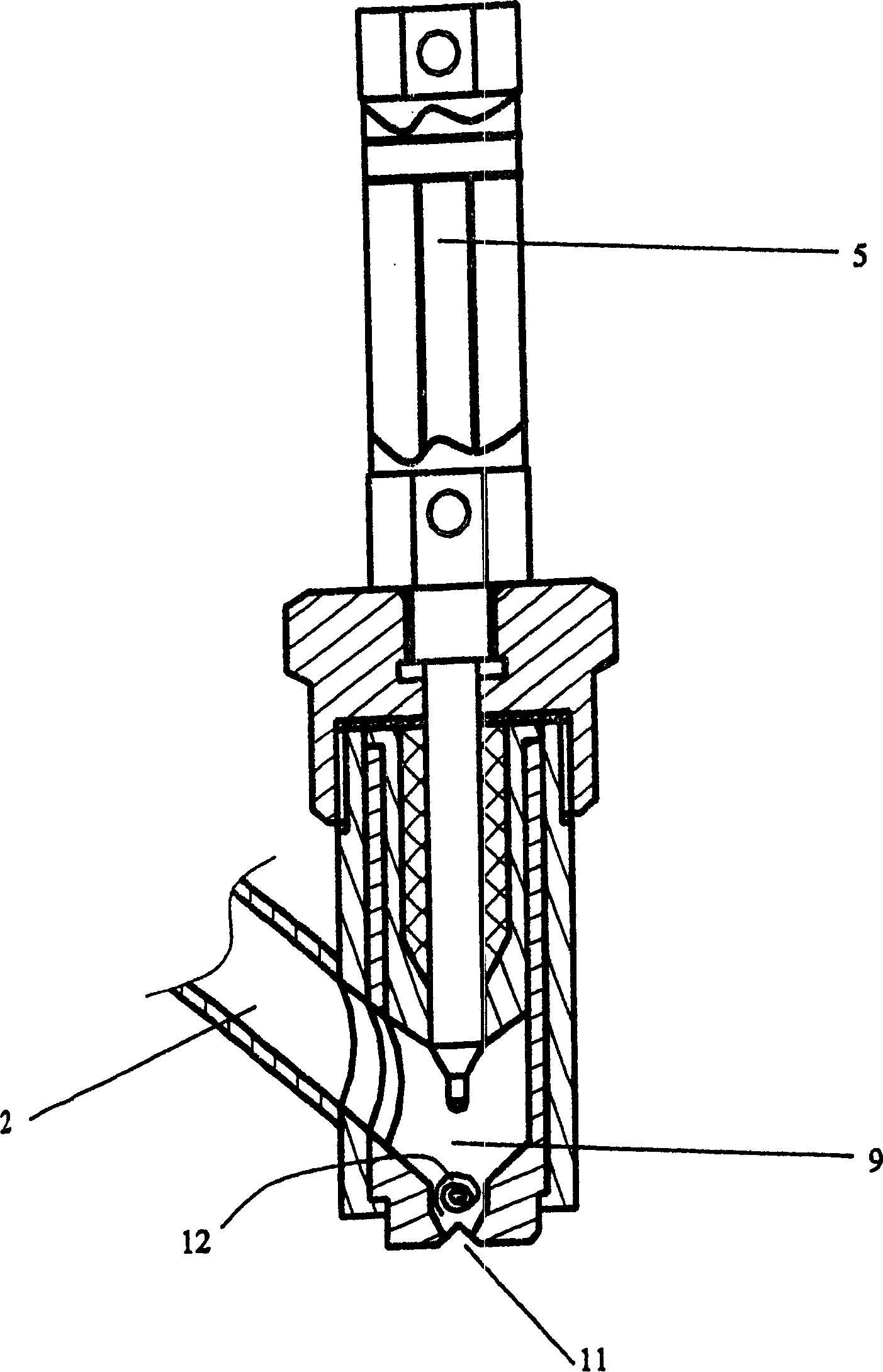

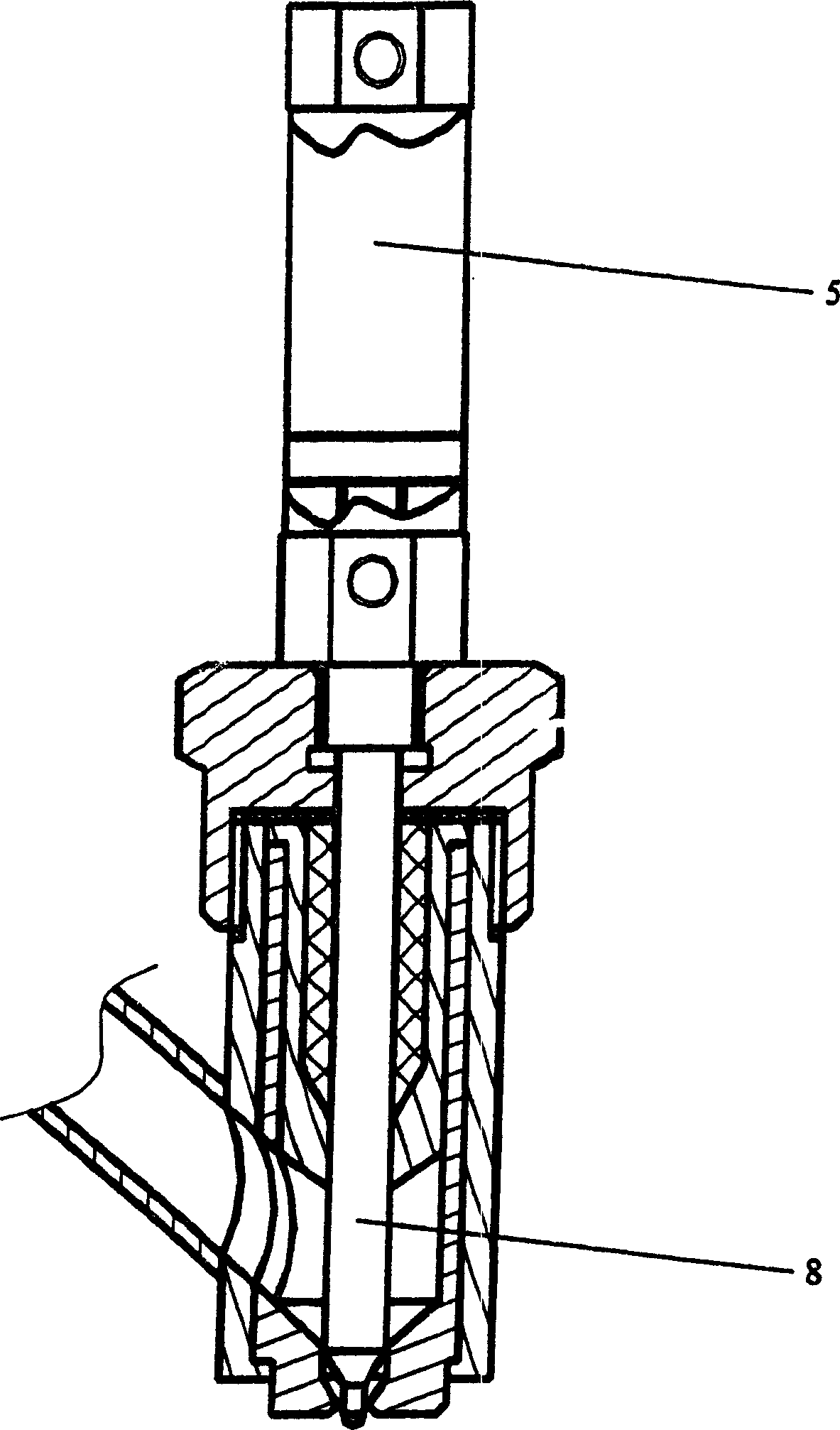

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings: figure 1 Shown are the components available for a self-cleaning nozzle assembly 1 for use with a textile processing machine (not shown).

[0047] The self-cleaning nozzle assembly 1 includes a nozzle housing 3 and a nozzle body 10 wrapped in the nozzle housing 3 . The nozzle housing 3 and the nozzle body 10 have corresponding fluid inlets 2 provided on the side walls.

[0048] The nozzle body 10 forms a fluid channel 9 . In this embodiment, this fluid channel 9 has a circular cross-section. At one side end of the fluid channel 9 it is provided with an outlet 11 . The outlet 11 has a generally oval or eye-shaped configuration.

[0049] The range of the fluid channel 9 is jointly defined by the inlet 2, the outlet 11 and the base of the sealing support 7 provided on the side wall. The seal support 7 may provide a substantially liquid-tight seal at the end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com