Pipeline joint crimping tool

A technology for crimping tools and pipeline joints, which is applied in the field of pipeline joint crimping tools, can solve problems such as troublesome operators, different types of specifications, and different materials, so as to achieve the effect of saving use costs and reducing operation troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

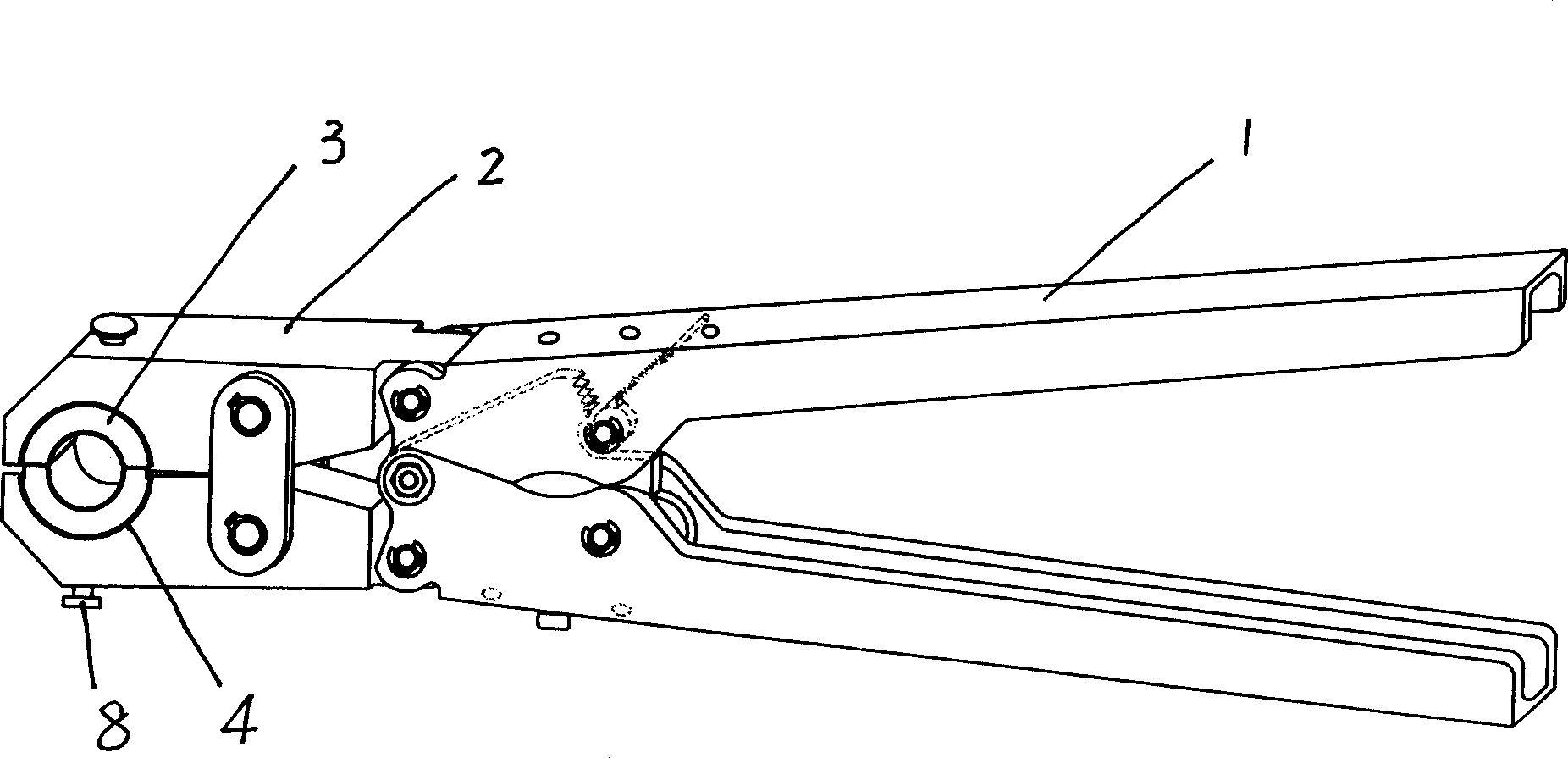

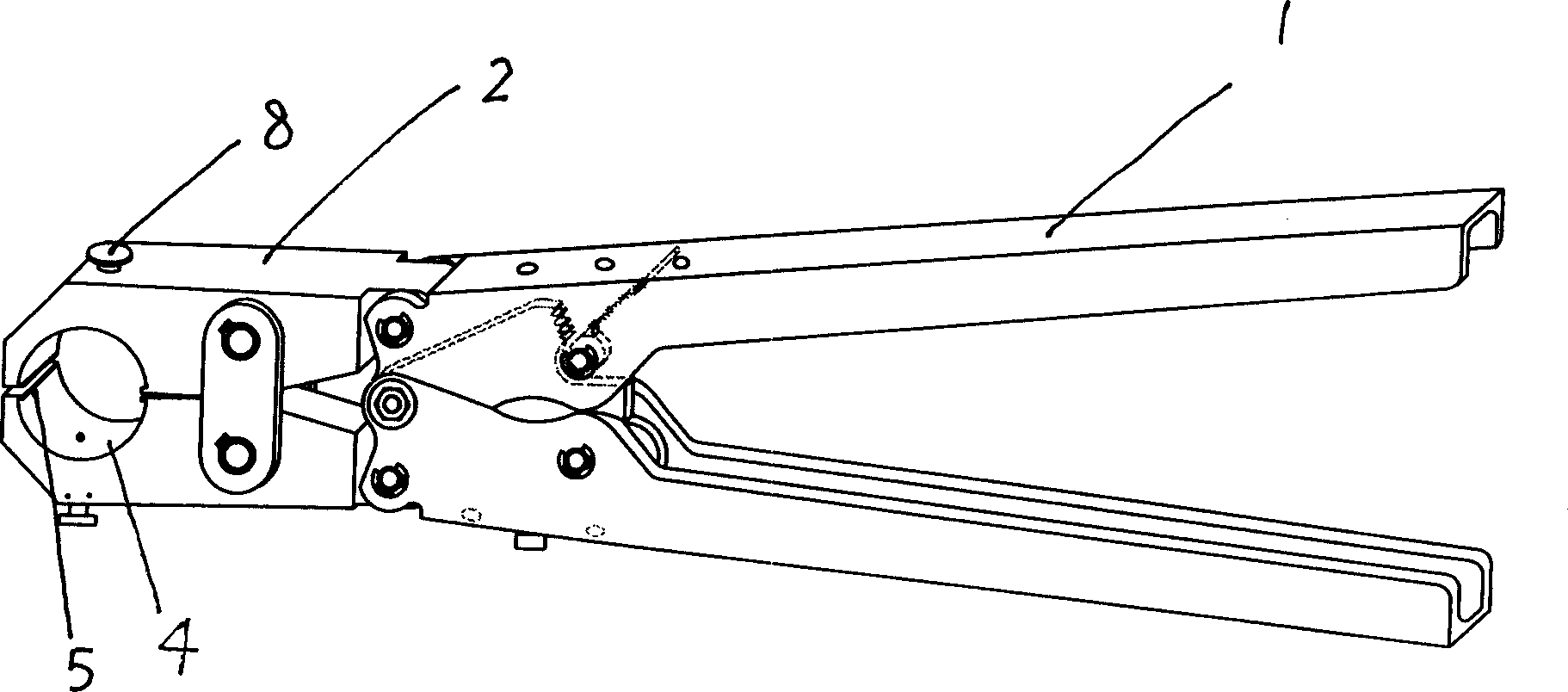

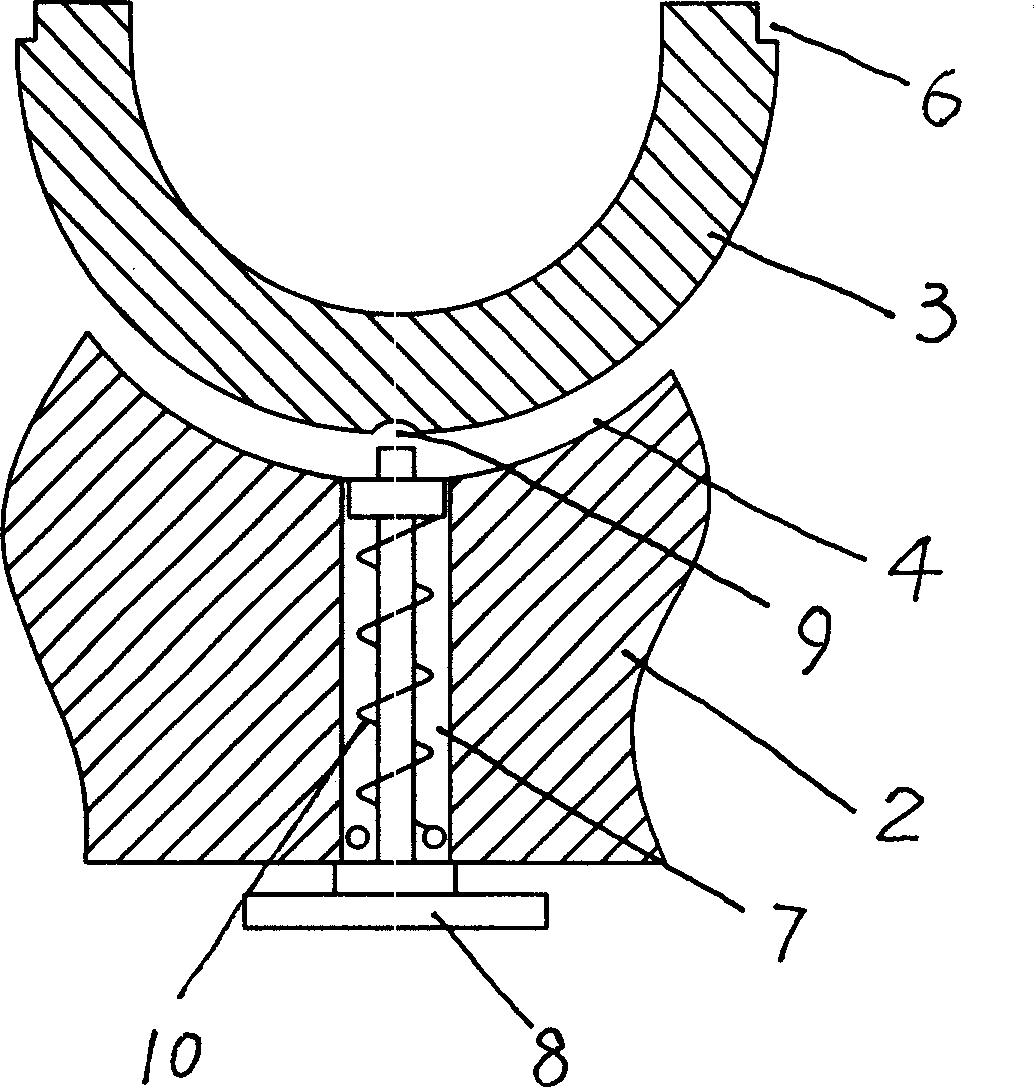

[0016] Example: such as figure 1 , figure 2 As shown, a pipeline joint crimping tool includes a crimping handle (1) and crimping pliers (2), and the two crimping pliers (2) are respectively provided with corresponding semicircular jaws (4) , the two crimping caps (3) are respectively embedded in the jaws (4), and the two sides of the port of the jaws (4) are respectively provided with convex strips (5) protruding inward, and the convex strips (5) are snapped into the crimping caps ( 3) In the grooves (6) opened on the outer walls on both sides of the port, a hole (7) is set in the middle of the jaw (4) in the crimping pliers (2), and a replacement button (8) is inserted in the hole (7). ), the end of the replacement button (8) protrudes slightly from the jaws (4) and is inserted into the cavity (9) on the outer wall of the crimping cap (3), and the replacement button (8) is covered with a spring (10), so that The replacement button (8) always faces the crimping cap (3).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com