Bagging device for rice processing

A bagging device and rice processing technology, which is applied in packaging and other directions, can solve the problems of high energy consumption, low work efficiency, and long time, and achieve the effects of reducing operation troubles, high work efficiency, and reducing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

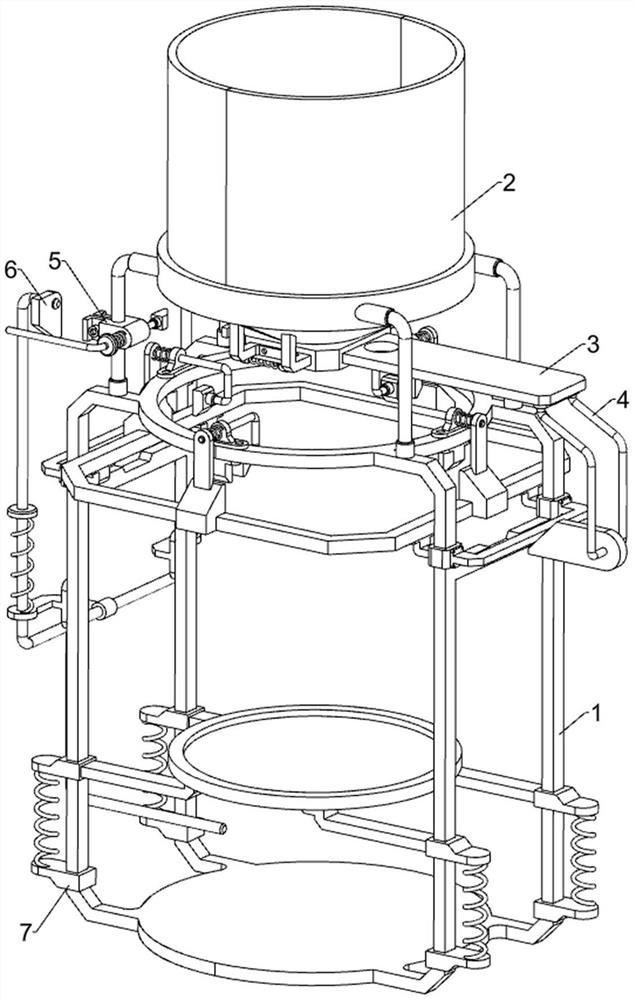

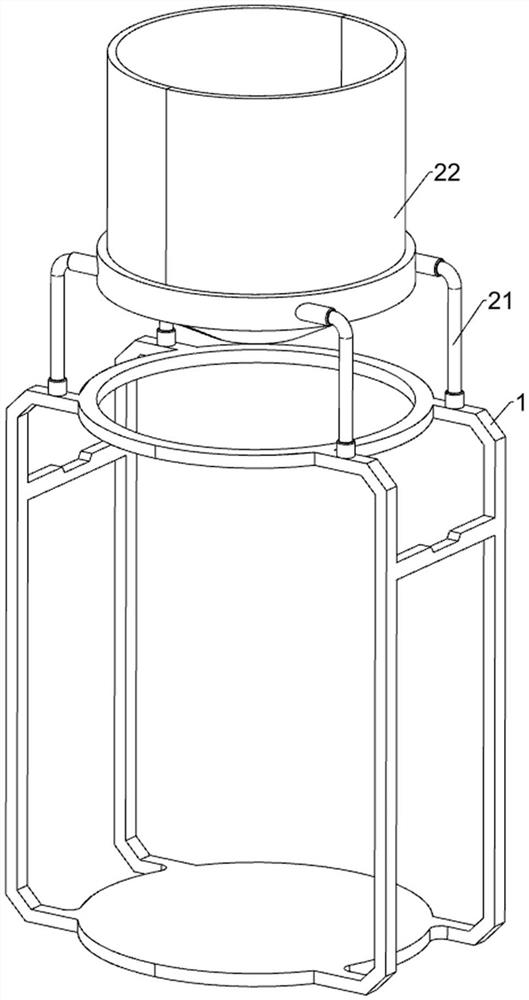

[0028] A bagging device for rice processing, such as Figure 1-3 As shown, it includes a frame 1 , a material storage assembly 2 and a blocking assembly 3 , the upper side of the frame 1 is provided with a storage assembly 2 , and the storage assembly 2 is provided with a blocking assembly 3 .

[0029] When the rice needs to be bagged, the rice is placed in the storage assembly 2, the rice will be blocked by the blocking assembly 3, and then the rice bag is placed on the lower side of the storage assembly 2, and then the blocking assembly 3 is controlled, so that the blocking assembly 3 no longer blocks the storage component 2, the rice in the storage component 2 will fall into the rice bag on the lower side due to gravity, and control the blocking component 3 to reset after the rice bagging is completed, so that the blocking component 3 blocks the storage component 2 again , and then replace another rice bag on the lower side of the material storage assembly 2, repeat the abo...

Embodiment 2

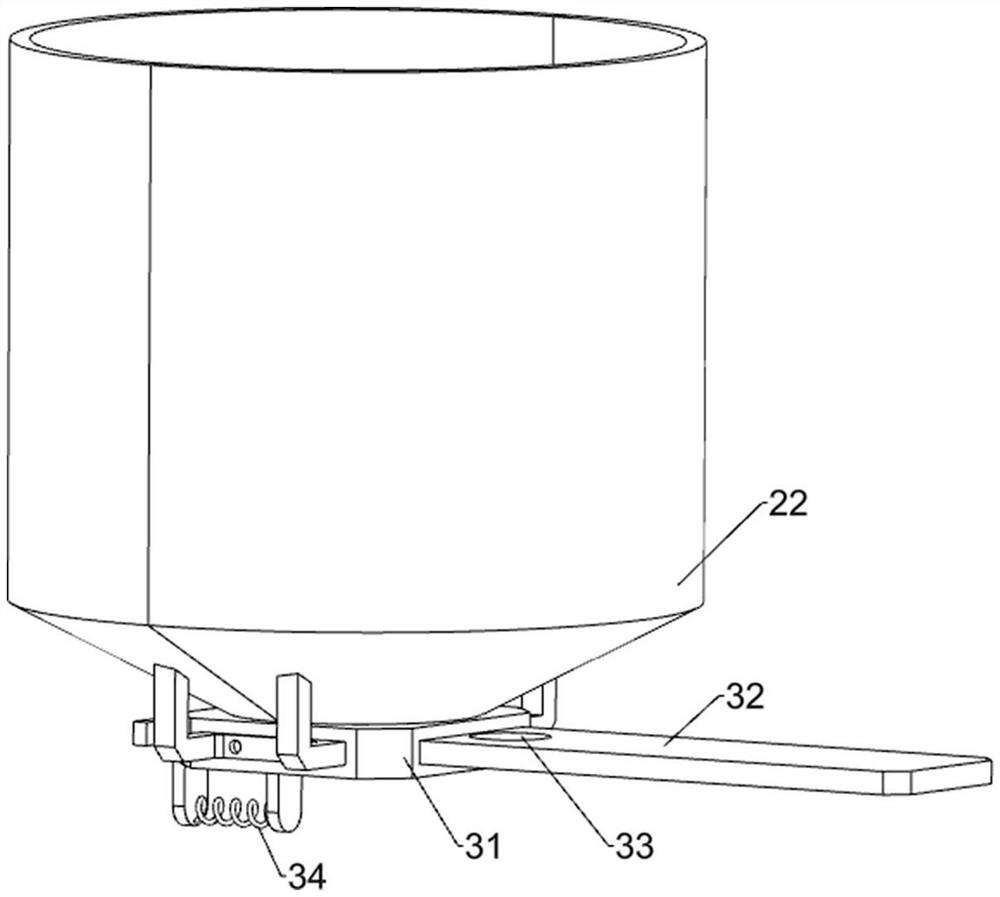

[0035] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a clamping assembly 4 is also included, and the clamping assembly 4 includes a slide bar 41, a first spring 42, a pressure block 43, a backing plate 44, a riser 45, a connecting rod 46, a first wedge block 47, a guide frame 48 and the push ring 49, the upper side of the frame 1 is evenly spaced slidingly connected with four slide bars 41, the first spring 42 is connected between the slide bars 41 and the frame 1, and the slide bars 41 are welded with pressure Block 43, four backing plates 44 are evenly spaced on the frame 1, the backing plates 44 cooperate with the pressure block 43, the outside of the slide bar 41 is welded with a vertical plate 45, and the lower side of the right part of the baffle plate 32 is welded with two front and rear Connecting rod 46, the first wedge-shaped block 47 is connected between the lower side of connecting rod 46, and the left a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com