Valve scale feed nozzle exhaust apparatus

An exhaust device and material feeding technology, which is applied in packaging, solid materials, transportation and packaging, etc., can solve the problems of lower measurement accuracy, easy damage to the bag opening, and material waste, so as to improve measurement accuracy, good sealing effect, and avoid wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

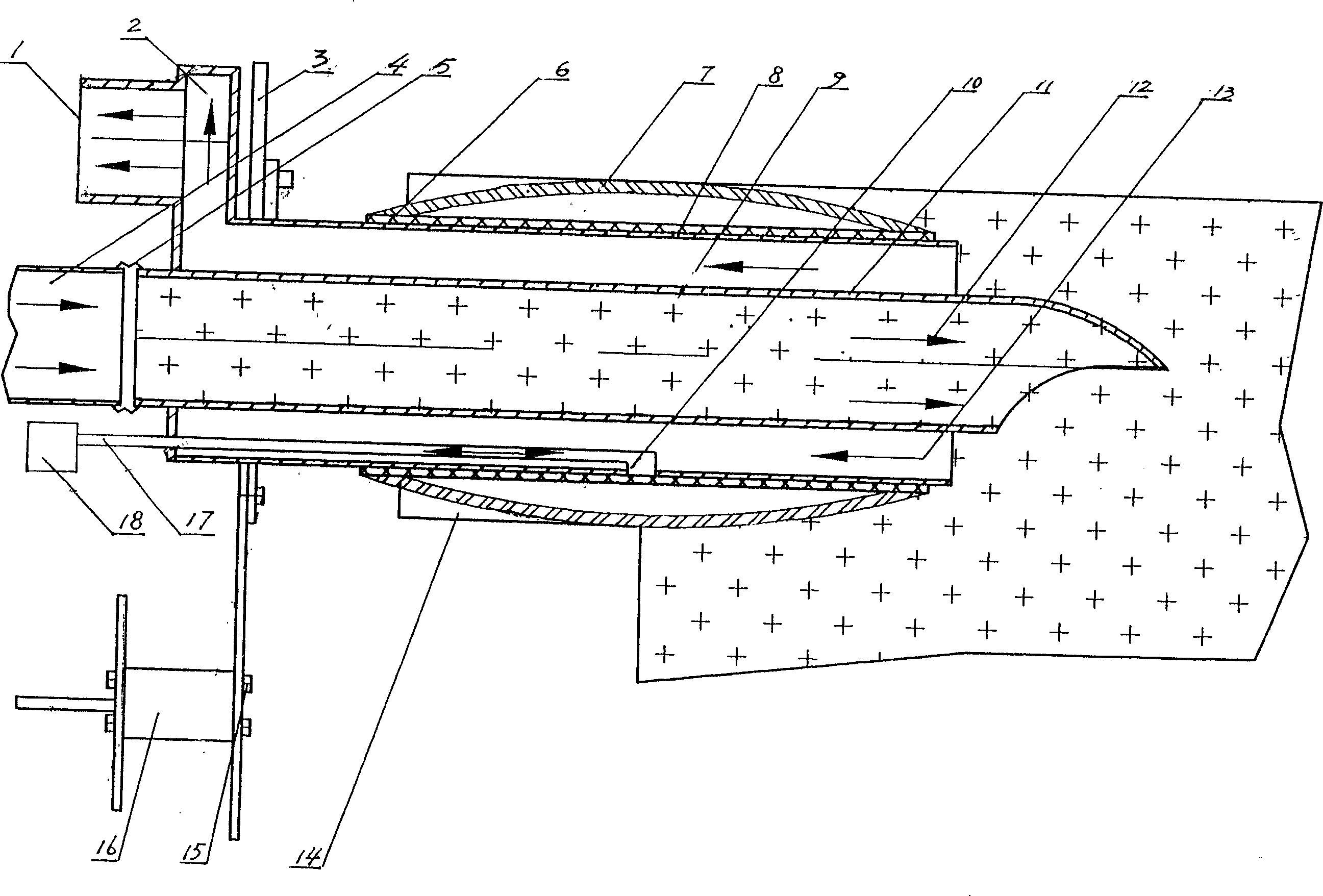

[0010] As shown in the accompanying drawings, the exhaust device of the feed nozzle of the valve port scale of the present invention contains a feed pipe 11, and the outside of the feed pipe 11 is covered with an exhaust pipe 8. The diameter of the outer circle of the feed pipe 11 is smaller than the diameter of the inner circle of the exhaust pipe 8 , so that an air duct 9 is formed between the outer circle of the feed pipe 11 and the inner circle of the exhaust pipe 8 . The front end of the exhaust pipe 8 and the feeding pipe 11 are open, and the front end and the feeding pipe 11 are sealed by means of an annular sealing plate 19 . A radial convex cavity 2 is processed on one side of the sealing part, and an exhaust port 1 is processed on the rear side wall of the radial convex cavity 2, that is, an annular sealing plate 19, and the exhaust port communicates with the subsequent collecting device through a pipeline. connect.

[0011] The rear end of the feeding pipe 11 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com