Dynamically-monitored double valve with anti-tiedown feature

A technology of anti-bolt and movable valve, applied in the direction of multi-way valve, valve device, engine components, etc., can solve the problem of unable to prevent control valve and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

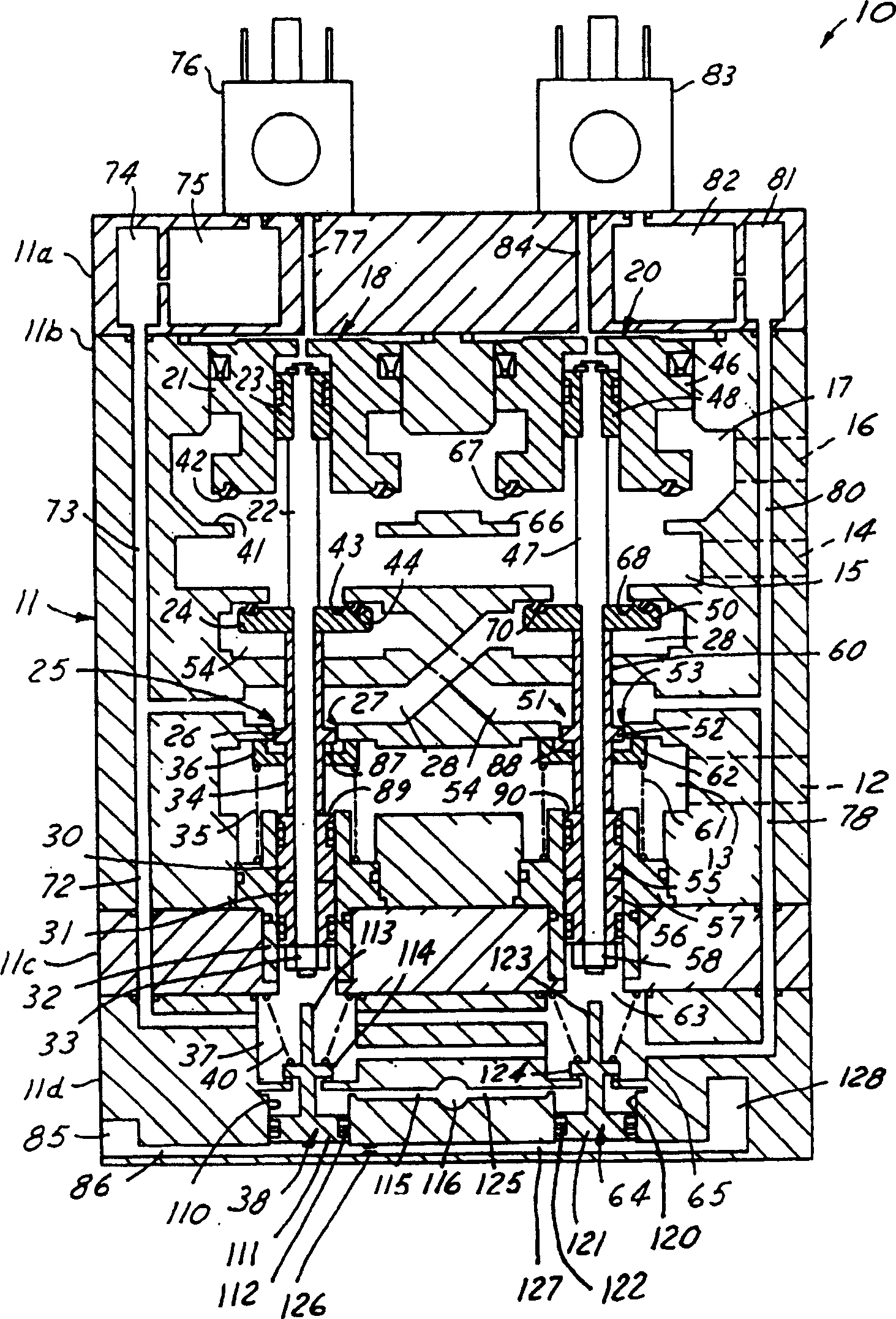

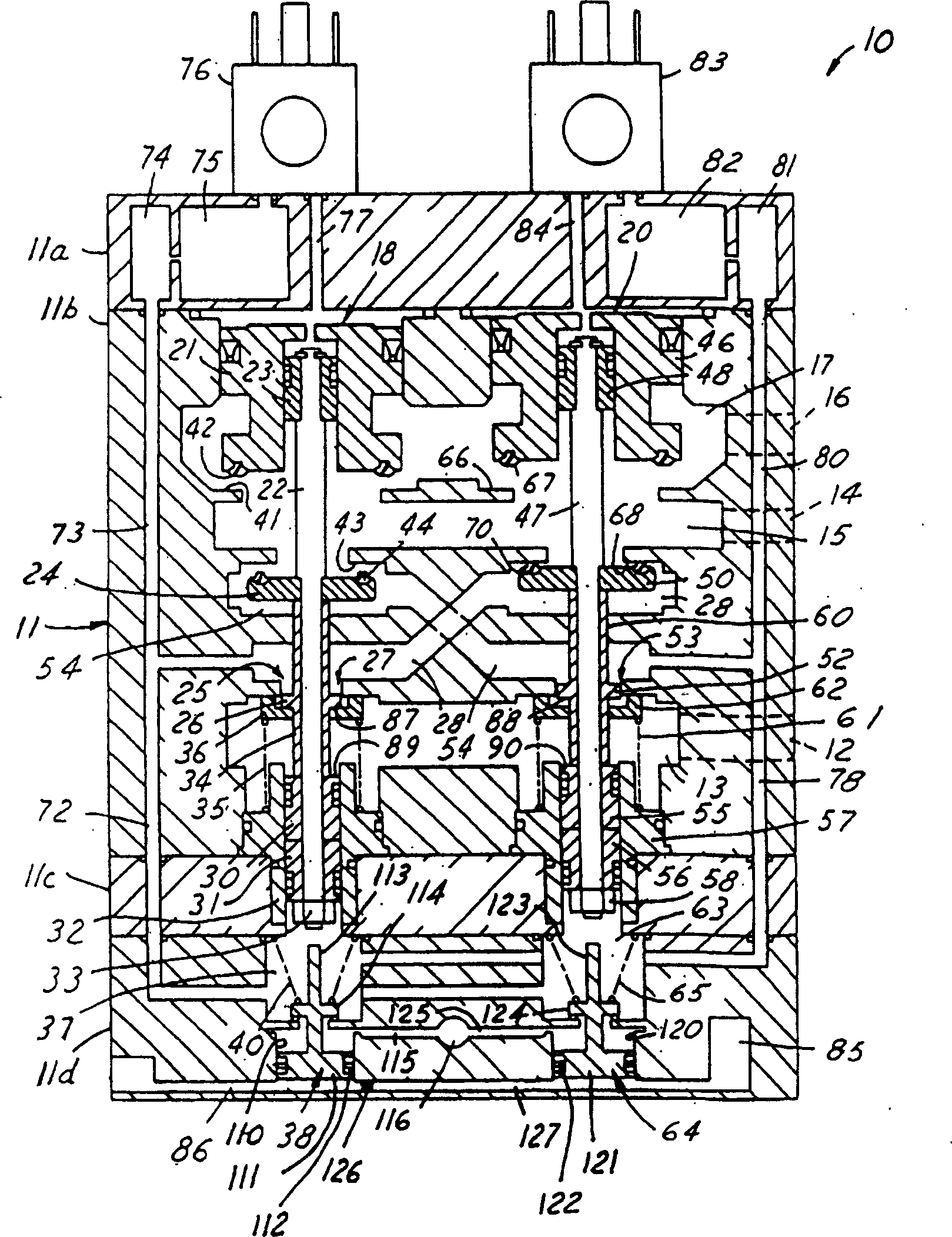

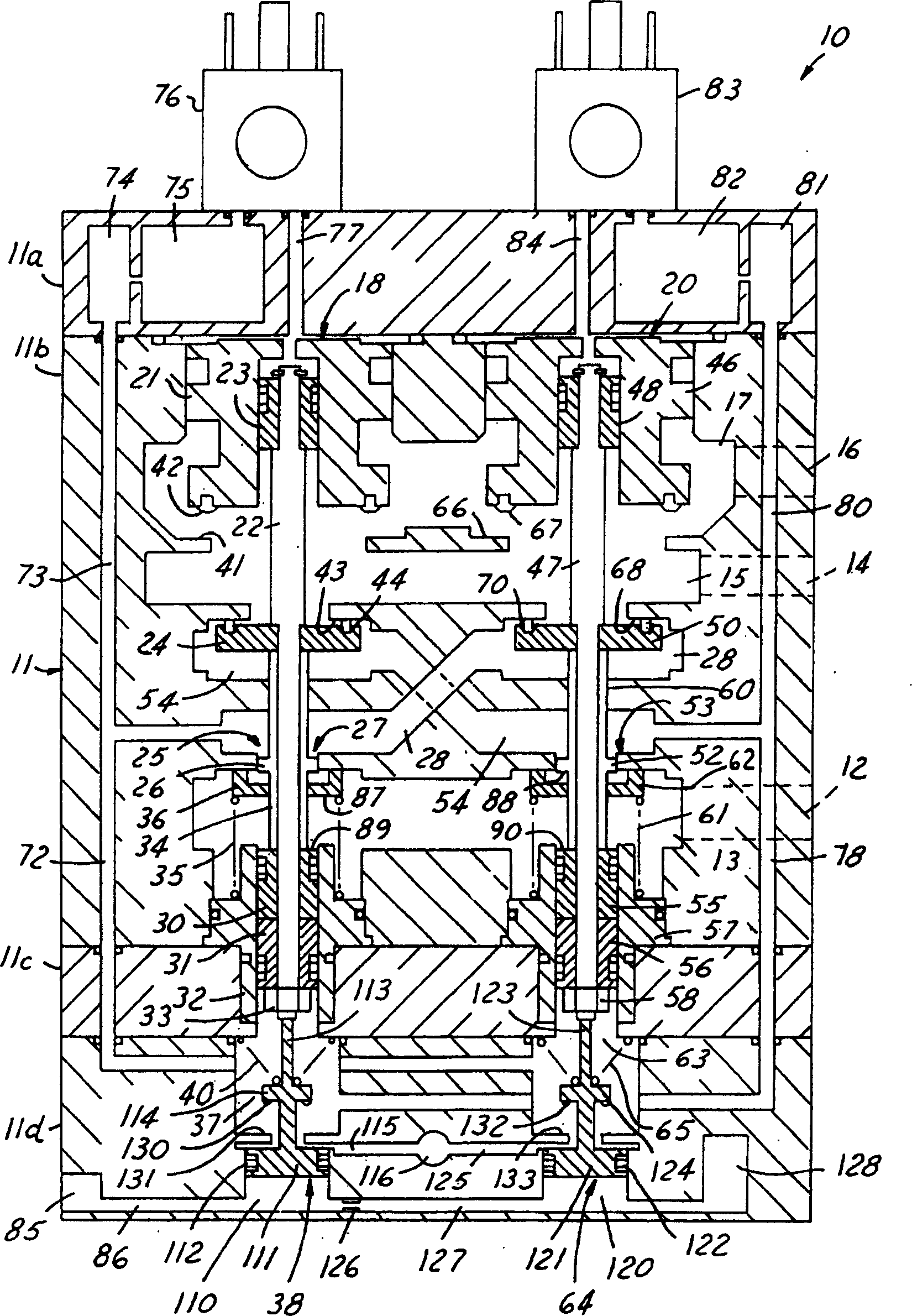

[0016] The following will refer to figure 1 , a control valve system in the form of a double valve 10 comprising a housing 11 with an inlet port 12 leading to an inlet chamber 13, an outlet port 14 leading to an outlet chamber 15 and a discharge port 16 leading to a discharge chamber 17 . Housing 11 may comprise separate blocks 11a-11d, each of which may be clamped or bolted together.

[0017] The chambers 13 , 15 and 17 are connected by a plurality of passages so as to form elongated holes for receiving the first movable valve unit 18 and the second movable valve unit 20 . The first movable valve unit 18 includes a discharge piston / poppet 21 slidably mounted on one end of a valve stem 22 via a piston 23 . The first active valve unit 18 also includes an inlet poppet valve 24 and a restrictor 25 . A disk shoulder 26 projects from a washer 34 secured to the valve stem 22 . Shoulder 26 is slidably received in channel 27 forming flow restrictor 25 , so that pressurized fluid f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com