Jet flow type smoke exhaust ventilator

A range hood, jet type technology, applied in the direction of removing oil fume, heating method, household heating, etc., can solve the problems of inconvenient cleaning and daily maintenance, increase energy consumption, low flue speed, etc., and achieve convenient cleaning and daily maintenance. , scientific and reasonable design, compact and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

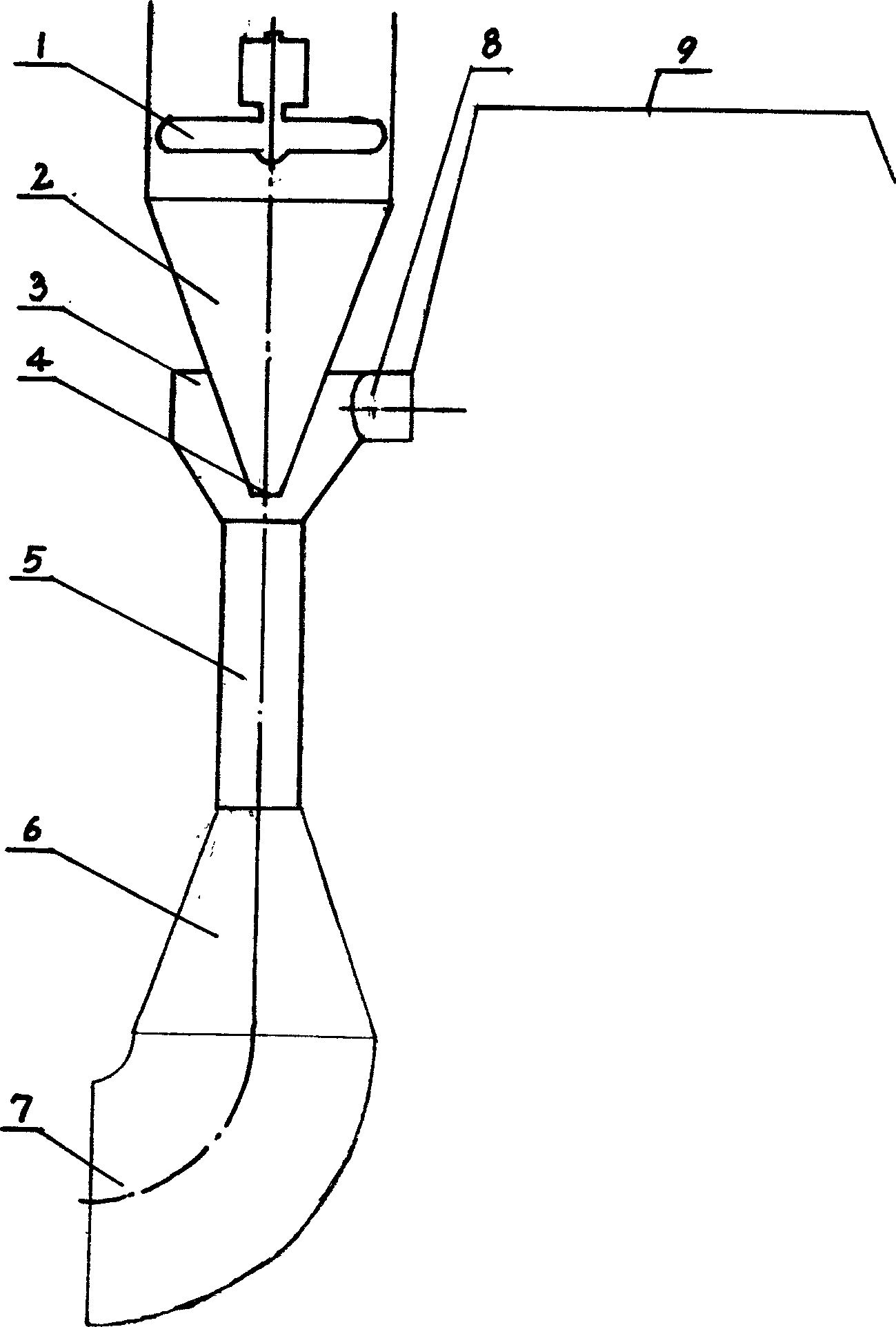

[0008] The jet-type range hood of the present invention comprises a power machine 1, a power air pipe 2, an injection port 4, a fume receiving chamber 3, a mixing pipe 5, a diffuser pipe 6, an exhaust pipe 7, a fume inlet pipe 8, and a fume collection hood 9. The power machine 1 is fixedly installed in an installation sleeve, the motor of the power machine faces the air inlet of the installation sleeve, and the fan blade faces the air outlet of the installation sleeve. The air inlet enters the power machine, and a filter screen is set on the air inlet to prevent sundries from being sucked into the motor from the air inlet of the installation sleeve. . The power air duct 2 is a tapered tube that shrinks in the shape of a trumpet, and its upper end is connected to the air outlet of the installation sleeve where the power machine 1 is installed....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com