Face and side cutter

A technology of three-sided cutting edge and milling cutter, which is applied in the direction of milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of difficult control of precision, time-consuming and inconvenient, and achieve high precision and easy and reliable adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

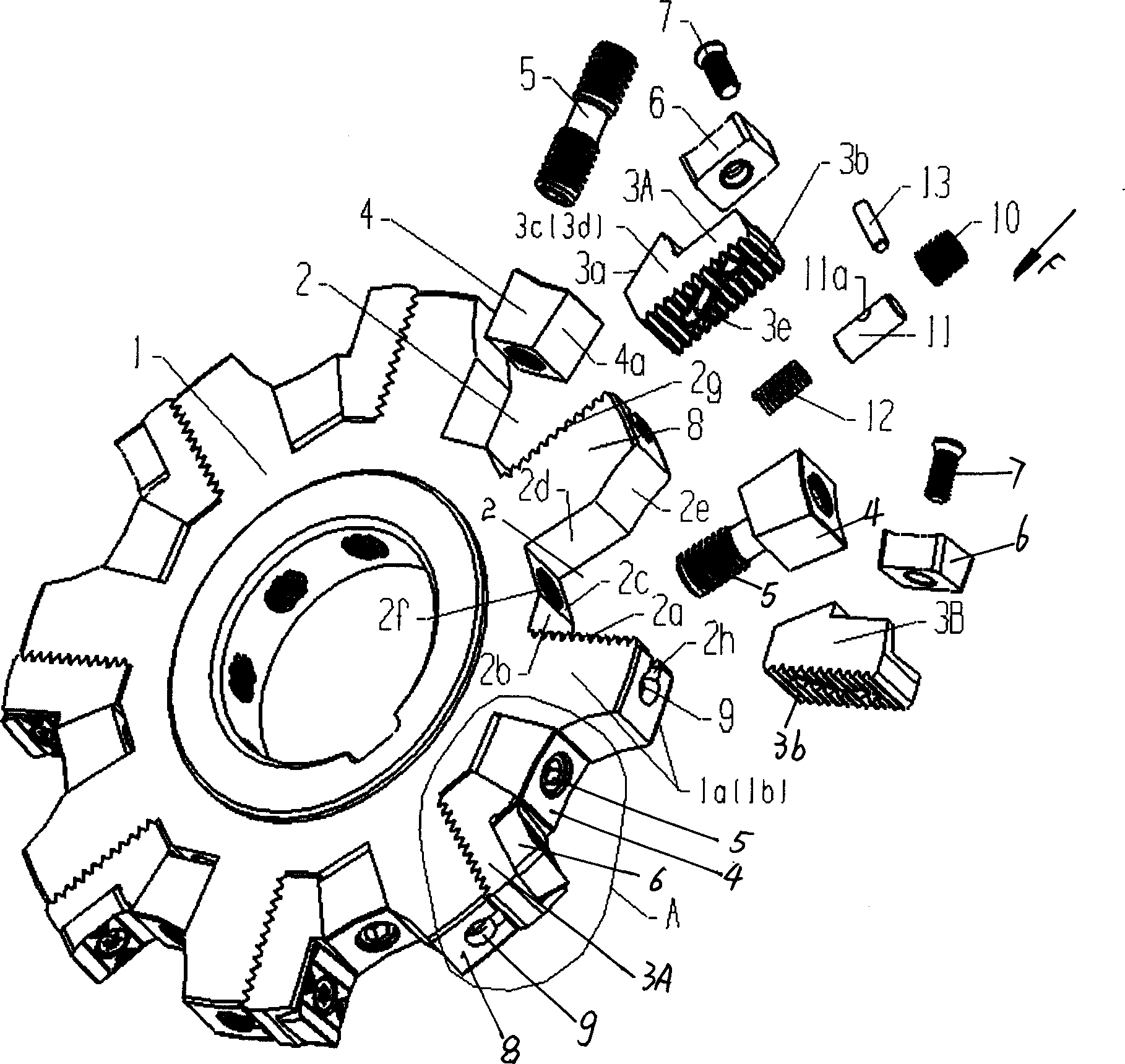

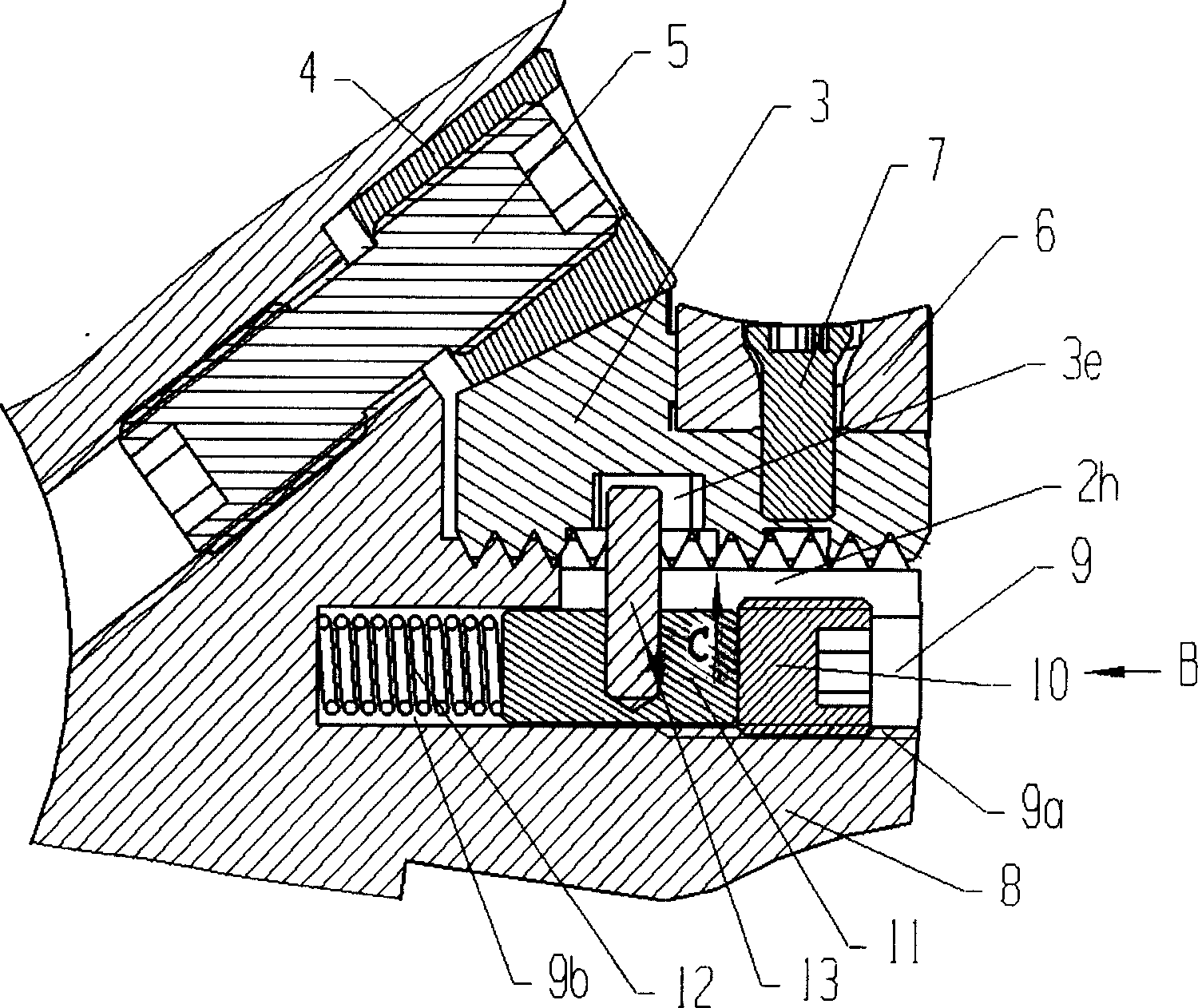

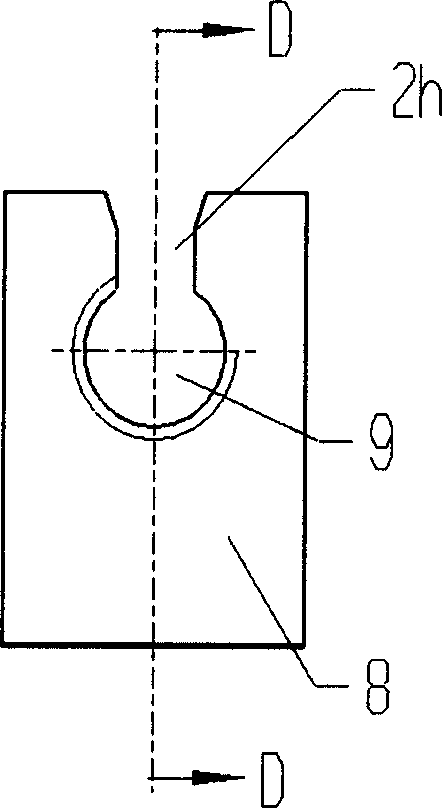

[0014] like Figure 1-Figure 2 As shown, the three-sided edge milling cutter of the present invention includes a disk 1 with chip pockets 2 distributed at intervals around the periphery, and is divided into left and right tool seats 3A, 3B, which are placed in the chip pockets 2 at intervals, and the screws 7 can be Fix the blade 6 on the tool seat 3A, 3B; the chip flute 2 is sequentially connected by a serrated surface 2a, three straight surfaces 2b, 2c, 2d and an arc surface 2e, and the serration surface 2a and the arc surface 2e are respectively It is connected to the outer edge of the disc 1; the bolt 5 is screwed on the disc 1 through the central threaded through hole of the pressing block 4 and the threaded through hole 2f on the second straight surface 2c of the chip flute 2, so that the inclined plane of the pressing block 4 4a presses the inclined surfaces 3a of the knife holders 3A, 3B, thereby wedging and fixing the knife holders 3A, 3B. The sawtooth surface 3b of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap