Resin coating apparatus for light solidifying rapid forming technique

A molding process and coating device technology, which is applied in the field of rapid prototyping, can solve the problems that are difficult to achieve and the amount of resin is difficult to control accurately, and achieve the effect of saving resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

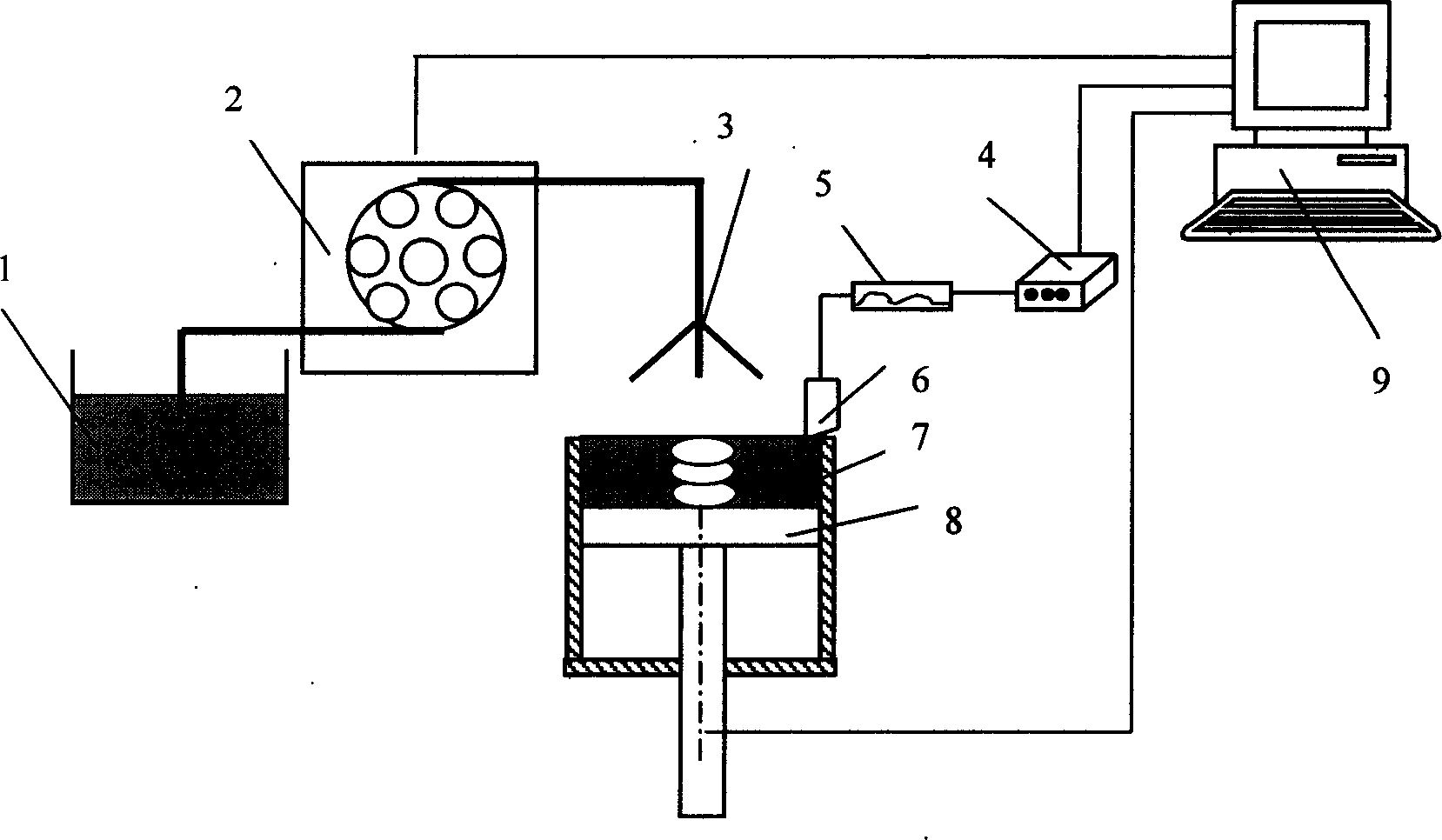

[0007] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0008] Referring to the accompanying drawings, the present invention includes a liquid storage tank 1 and a peristaltic pump 2 controlled by a computer 9 that communicates with the liquid storage tank 1. The peristaltic pump 2 communicates with the spray nozzle 3 arranged at the distribution point through a pipeline. A cylinder 7 and a piston 8 closely matched with the cylinder 7 and controlled by a computer 9 are arranged directly under the spray head 3. The space formed by the upper surface of the piston 8 and the inner cylindrical surface of the cylinder 7 serves as a resin tank for containing resin. A scraper 6 , a transducer 5 connected to the scraper 6 and an ultrasonic generator 4 controlled by a computer 9 are also arranged at the position where the upper end of the piston 8 is on the same level as the opening of the cylinder 7 .

[0009] During produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com