Device and methods for inspecting soldered connections

A welding point and ground connection technology, applied in measuring devices, optical testing flaws/defects, instruments, etc., can solve problems such as reducing image clarity, inspecting upper and lower soldering points, and increasing the overall price of inspection devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

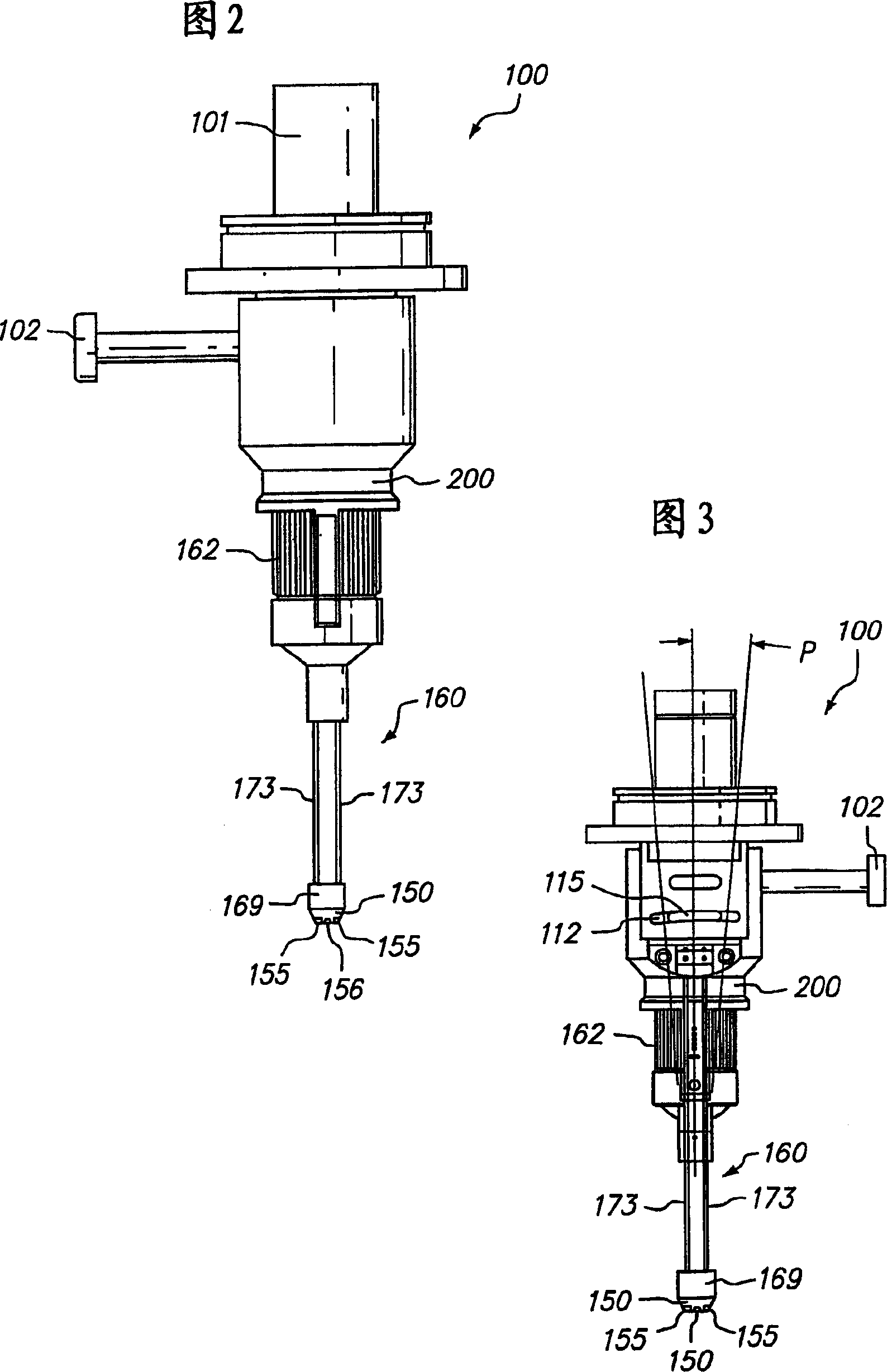

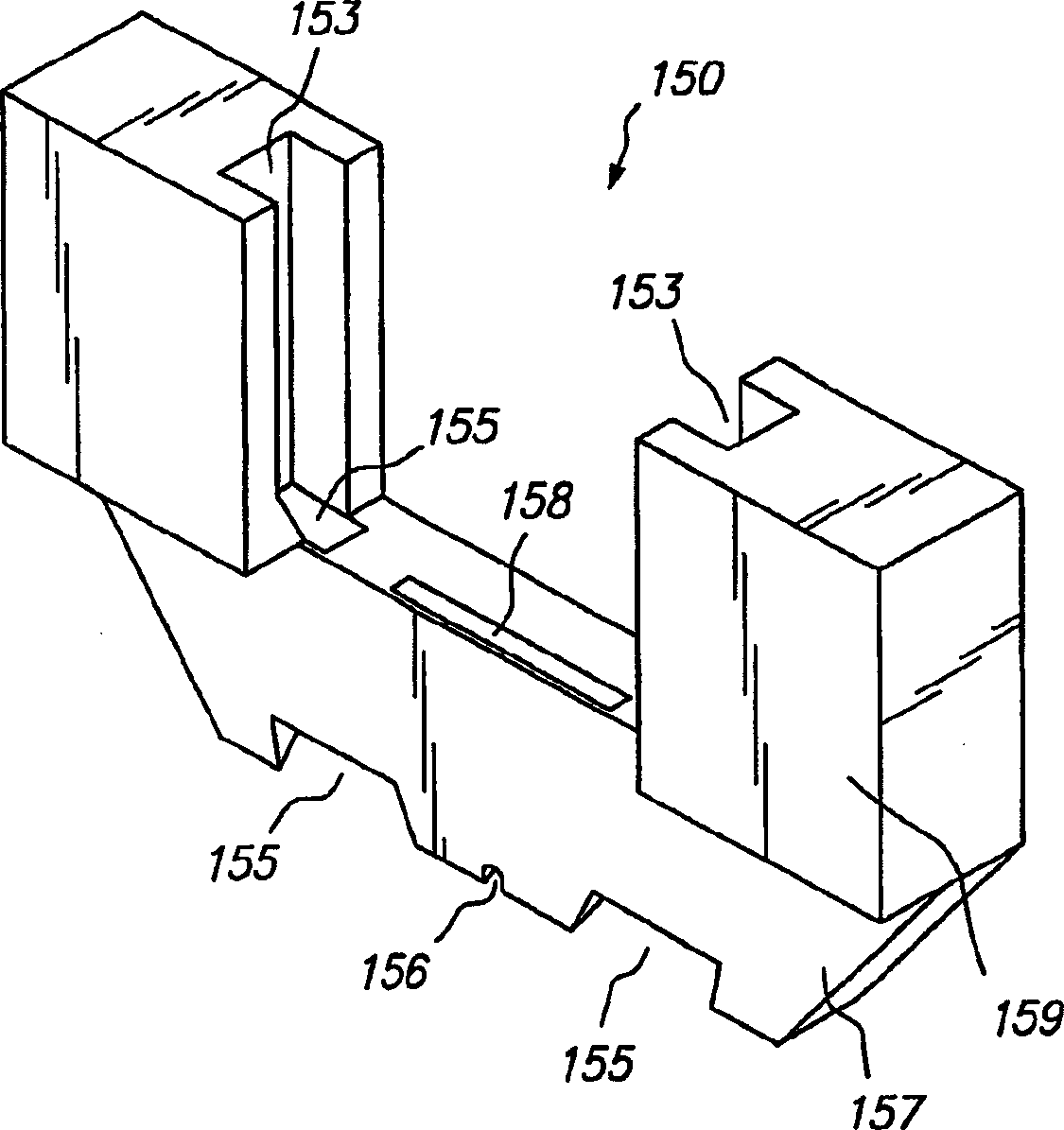

[0019] The invention includes an inspection apparatus for inspecting solder joints between a substrate and an integrated circuit. The detection device includes a base part and an optical inspection unit connected with the base. The base also includes a substantially horizontal working area in which an element to be inspected is placed. The optical inspection unit can move vertically and rotate relative to the working area.

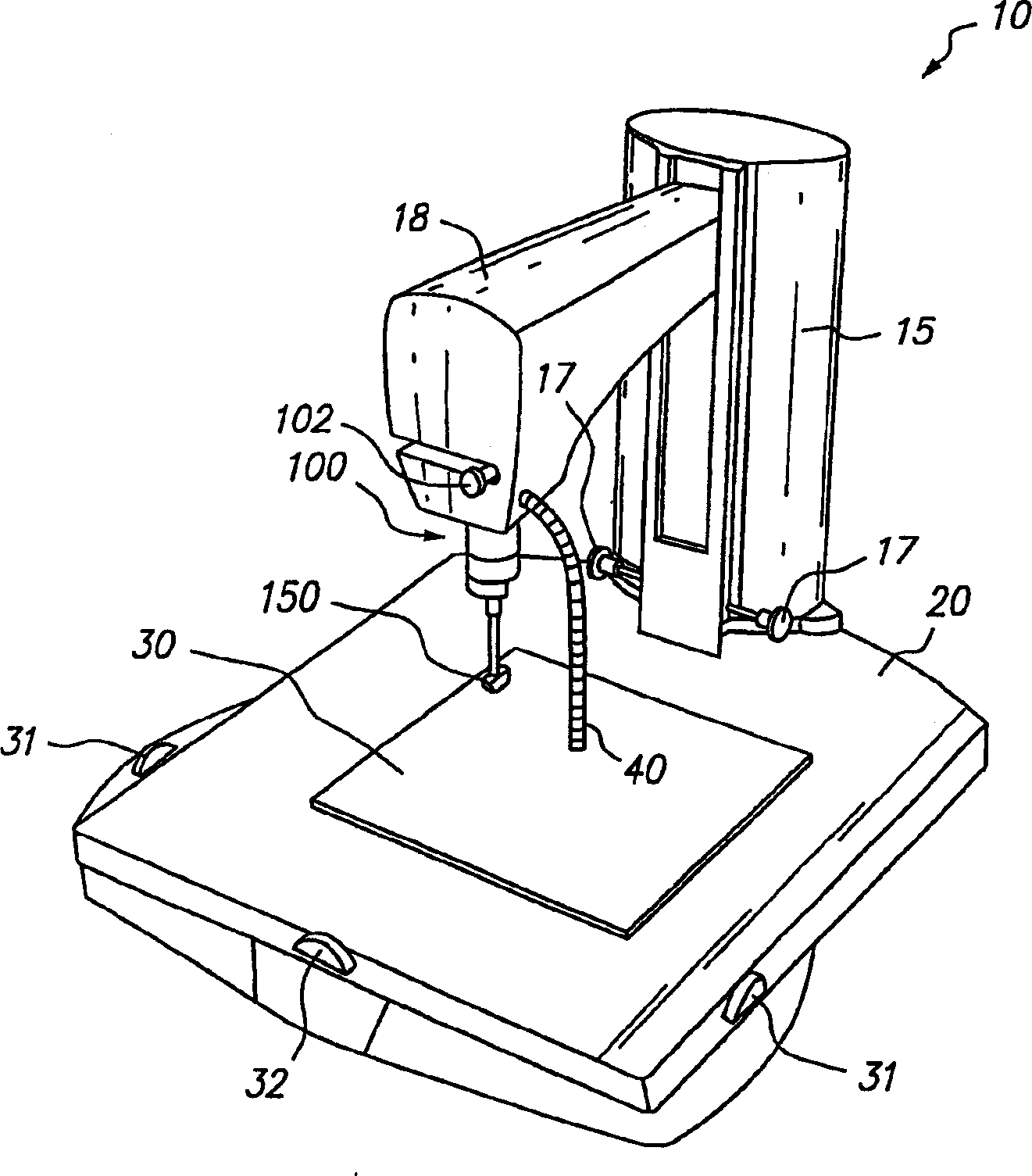

[0020] Now refer to figure 1 , which shows a detection device 10 according to the present invention. The detection device 10 comprises a base part 20 and an optical inspection unit 100 . The base member 20 also includes a horizontal working surface 30 that can move relative to the optical inspection unit 100 along a vertical plane and a horizontal plane.

[0021] The working surface 30 is movable by turning knobs 31 and 32, which are operatively connected to the working surface 30 by known mechanical components. Alternatively, the working surface 30 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com