Method for bending large sectional steel

A technology of bending forming and processing methods, which is applied in the field of sheet metal processing, can solve problems such as affecting the construction period, failing to complete engineering tasks on time, increasing transportation costs, etc., and achieving the effect of simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

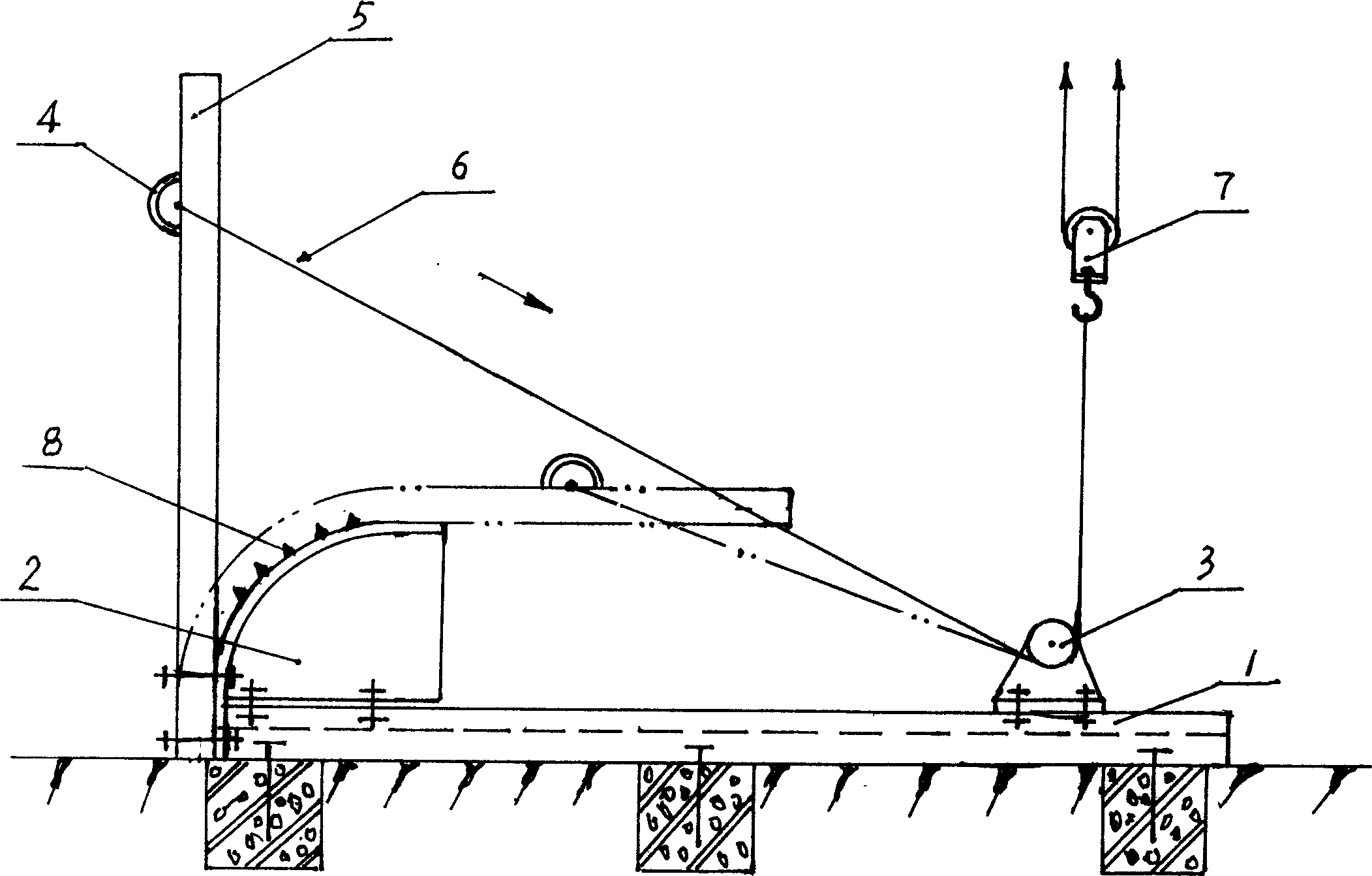

[0014] Referring to the accompanying drawings, take the processing of Q235-28# I-beam curved rail as an example to make a specific explanation: First, press a bending mold 2 and a fixed pulley 3 on the workbench 1 of the sheet metal processing factory respectively, and use bolts, The nut is fixed; the bending mold 2 determines the bending arc radius and arc length of the template according to the needs of the curved shape of the design, the extension of the template is close to the end face of the workbench 1, and the distance between the fixed pulley 3 and the extension of the template of the bending mold 2 greater than the length of the workpiece 5 after bending. Then, after the workpiece is blanked according to requirements, a device 4 for connecting the traction rope is welded at one end of the workpiece 5. The device 4 for connecting the traction rope is a pull pile, and the pull rope 6 is sleeved on the pull pile ; The other end of the workpiece 5 is press-fitted on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com