Braker for shuttle of tubular knitting machine

A technology for brakes and circular looms, applied to circular looms, looms, textiles, etc., can solve the problems of complicated manufacturing process of two-way springs, troublesome replacement and installation, unfavorable promotion and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

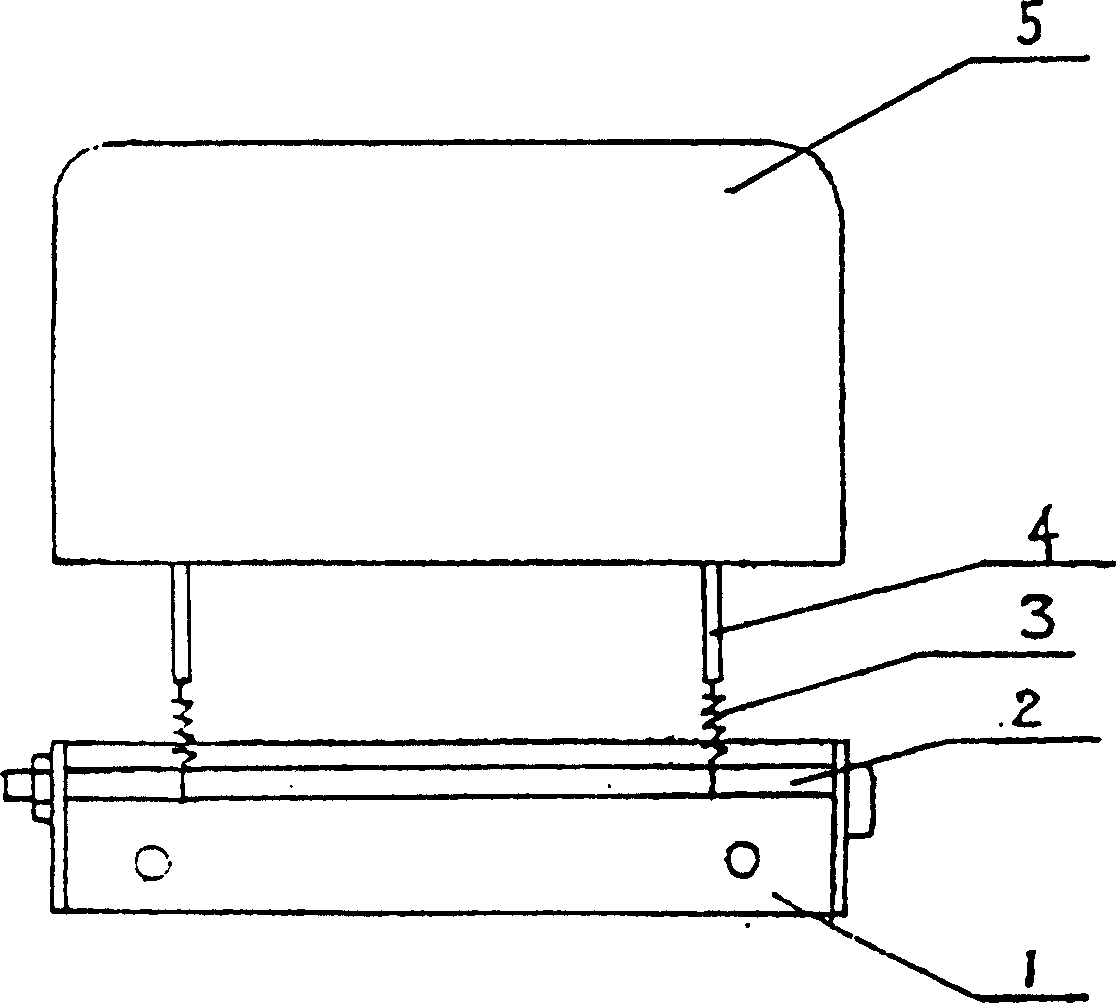

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

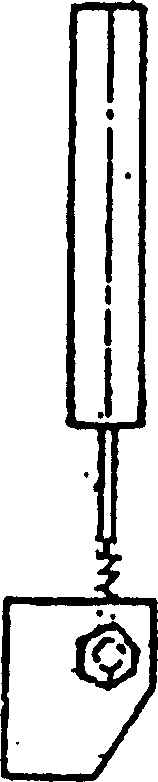

[0013] In the brake for a circular loom shuttle of the present invention, the shaft 2 is installed on the base 1, and two springs 3 with the same diameter and the same elastic coefficient are respectively hung on the shaft 2 through a hook at one end, and can freely rotate around the shaft. The material of spring 3 can be selected 45 steels for use, and the hook of spring 3 other ends is hung on the support 4 that connects double-sided cowhide 5 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com