Cutter head for cutter head changeable entrydriving mechine

A roadheader and cutter technology, which is applied to mining equipment, earthwork drilling, tunnels, etc., can solve problems such as inability to adapt to soil conditions and single cutter head form, and achieve the effects of convenient conversion, low cost, and good soil balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

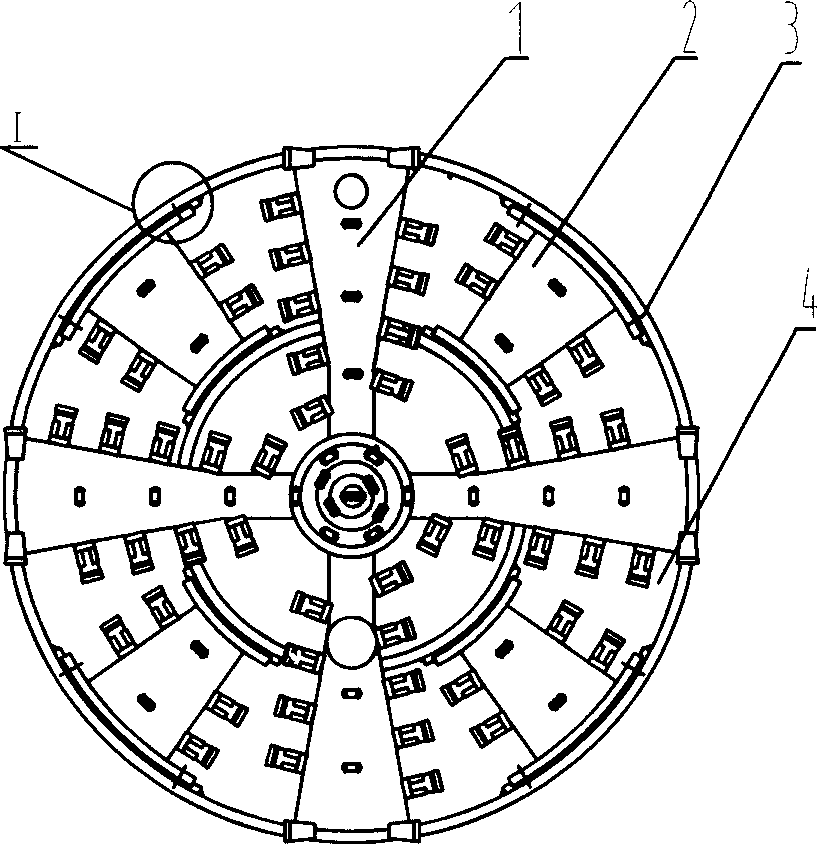

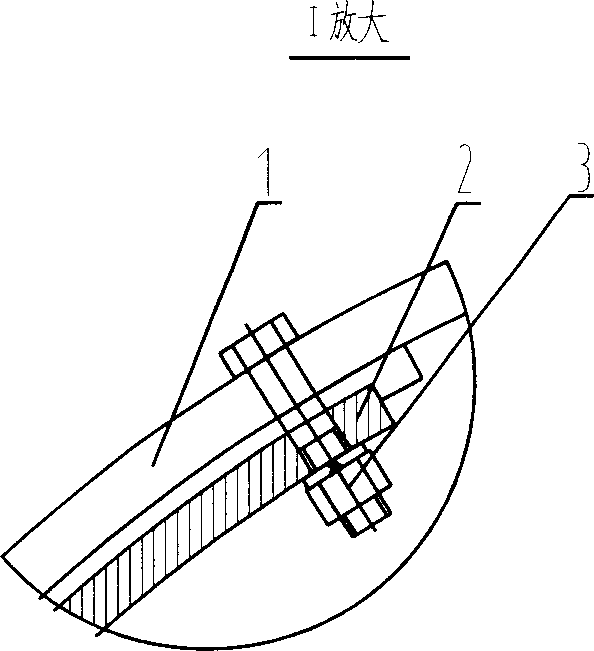

[0016] like figure 1 , figure 2 As shown in the figure, the present invention is composed of a spoke type cutter head 1, a panel type box cutter head group 2 and a bolt 3. The spoke type cutter head 1 and the panel type box cutter head group 2 are independent components respectively, and the cutter head panel is in the form of spokes. When the cutter head is a type of cutter head, the cutter head panel adopts the spoke type cutter head 1; or when the cutter head panel is a panel type, the panel type box cutter head group 2 is connected to the large box body seat 11 and the spoke type cutter head by bolts 3. The panel-type cutter head 4 is formed on the small box base 12 . The aperture ratio of the cutter head can be changed by selecting different sizes of the panel box cutter head group 2 .

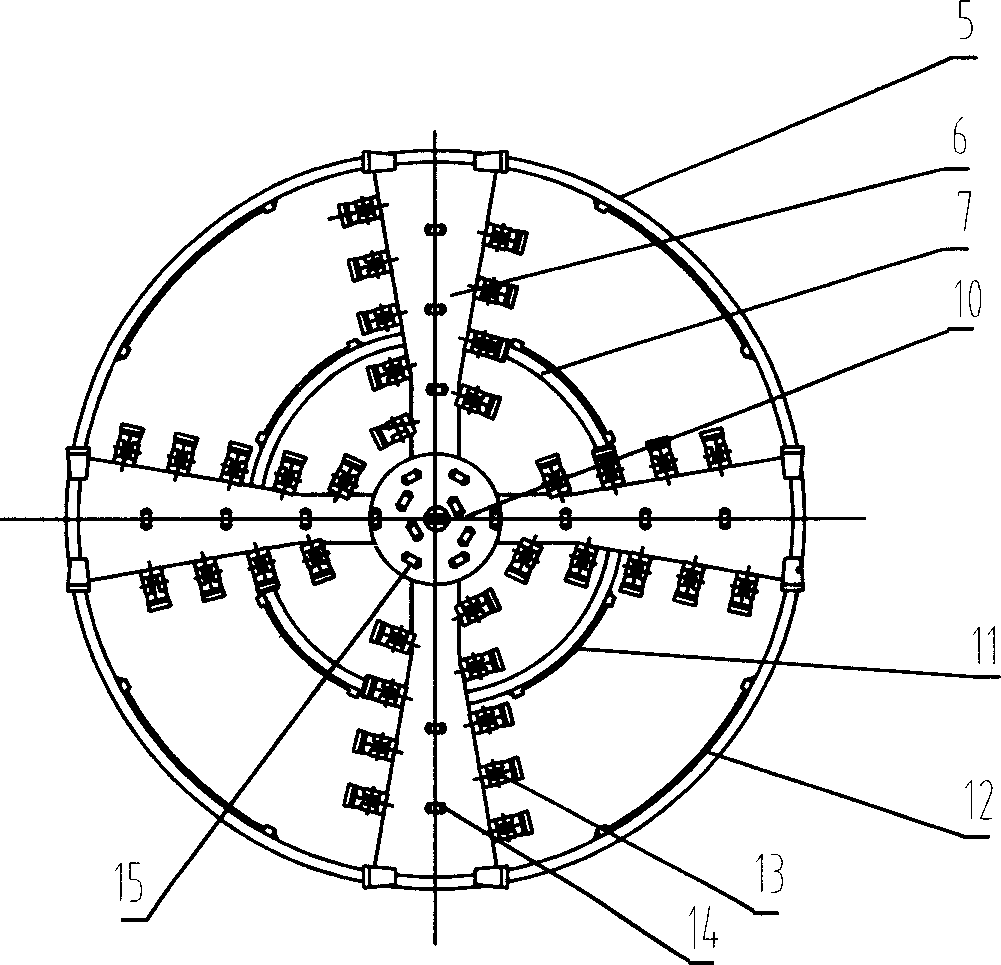

[0017] like image 3 , Figure 4 As shown, the spoked cutter head 1 is composed of a disc outer ring 5, four spoke-shaped spokes 6, a ring rib 7, a front panel 8, a rear panel 9, a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com