Master and auxiliary combustion device

A technology of main burner and auxiliary burner, which is applied in the direction of burner, gas fuel burner, and the combination of multiple burners, can solve the problems of reduction of gas volume, deterioration of flame flammability, and narrow flame hole of incision, etc. Achieve the effect of increasing the amount of gas and improving the flame flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

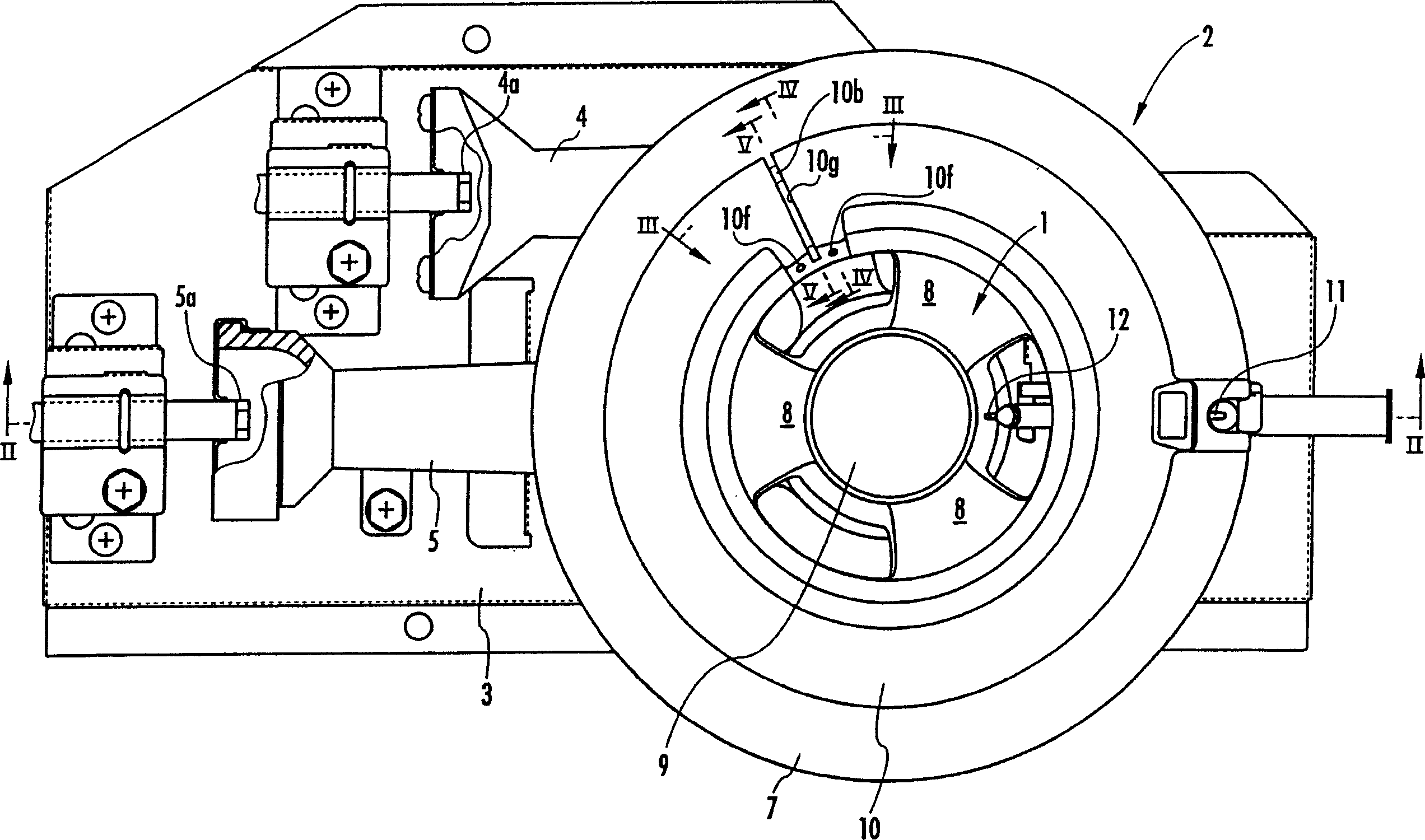

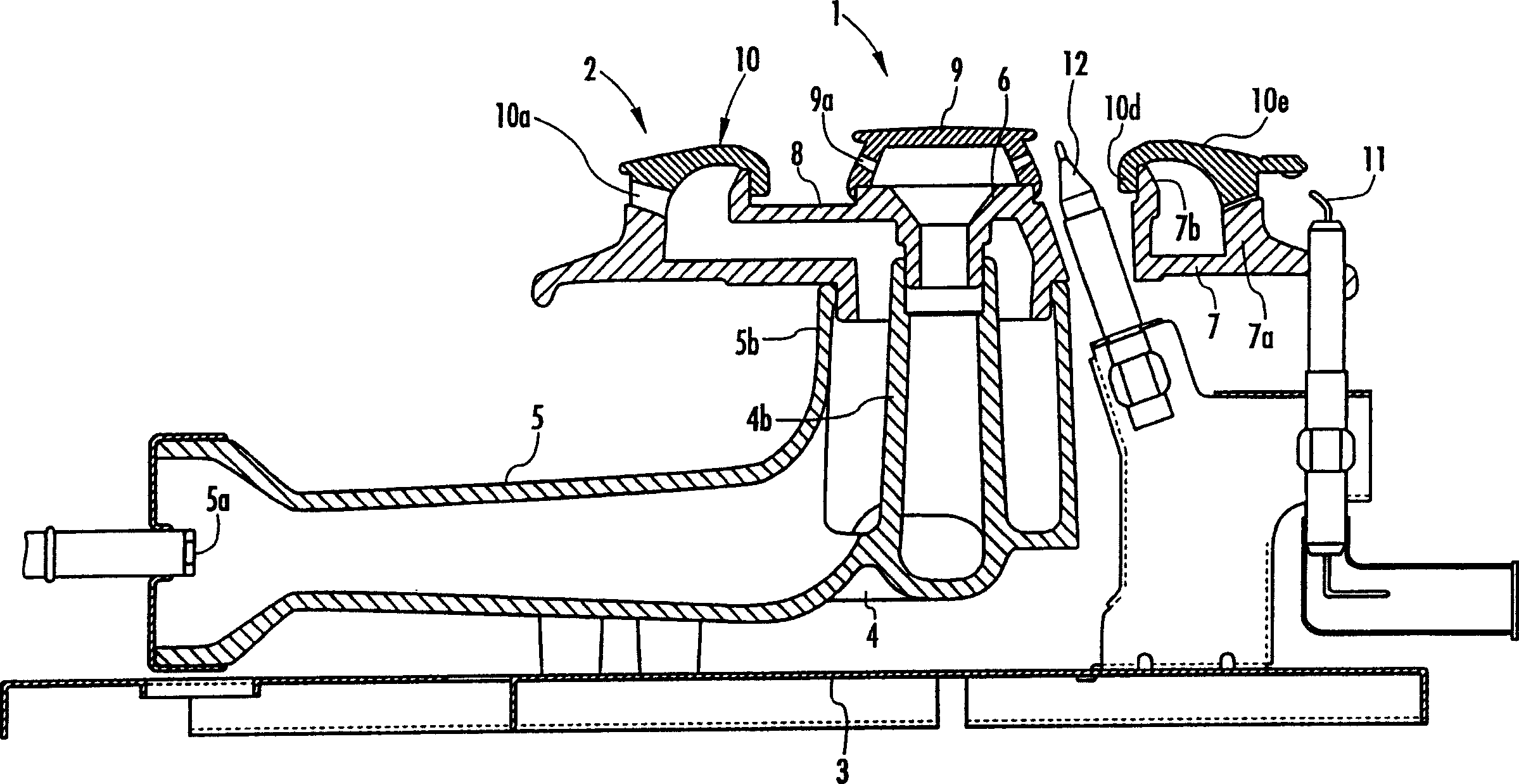

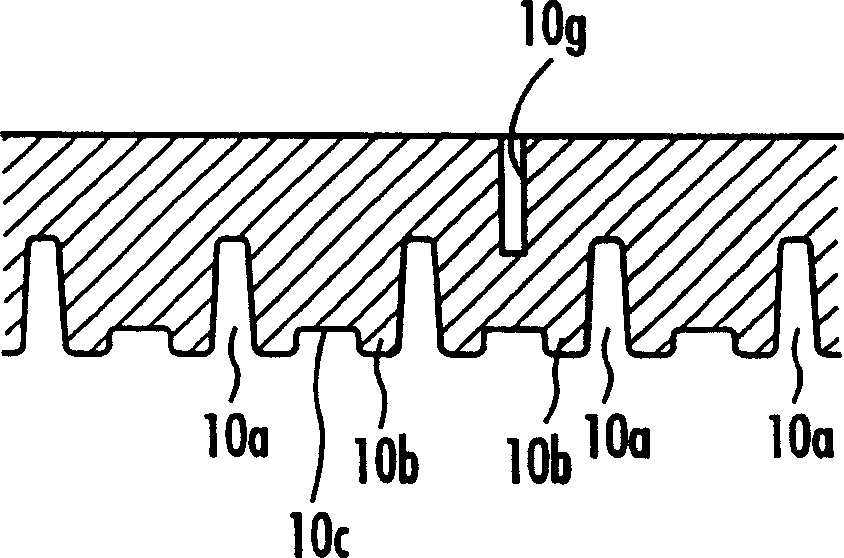

[0021] figure 1 , figure 2 The shown burner is a main and auxiliary burner composed of an auxiliary burner 1 and a main burner 2 surrounding the auxiliary burner 1, and the main and auxiliary burners are fixedly placed on a furnace base 3 inside a furnace body (not shown). superior. The main and auxiliary burners have an auxiliary burner mixing tube 4 and a main burner mixing tube 5 . And make each gas nozzle 4a, 5a face the upstream end of respective mixing pipe 4, 5, to generate in each mixing pipe 4, 5 the gas ejected from each gas nozzle 4a, 5a and the ejection of accompanying gas for suction Comes once the air is mixed with the mixture. Both mixing pipes 4, 5 are integrally formed at the downstream side thereof, and are integrally cast from cast iron. The integral part of the two mixing tubes 4 and 5 is formed by an inner tube 4b opening above the downstream ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com