Refrigeration cycle apparatus

A technology of circulation device and refrigerant, which is applied in gas cycle refrigerators, irreversible cycle compressors, refrigerators, etc., can solve the problems of reliability decline and pressure rise of refrigeration cycle devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

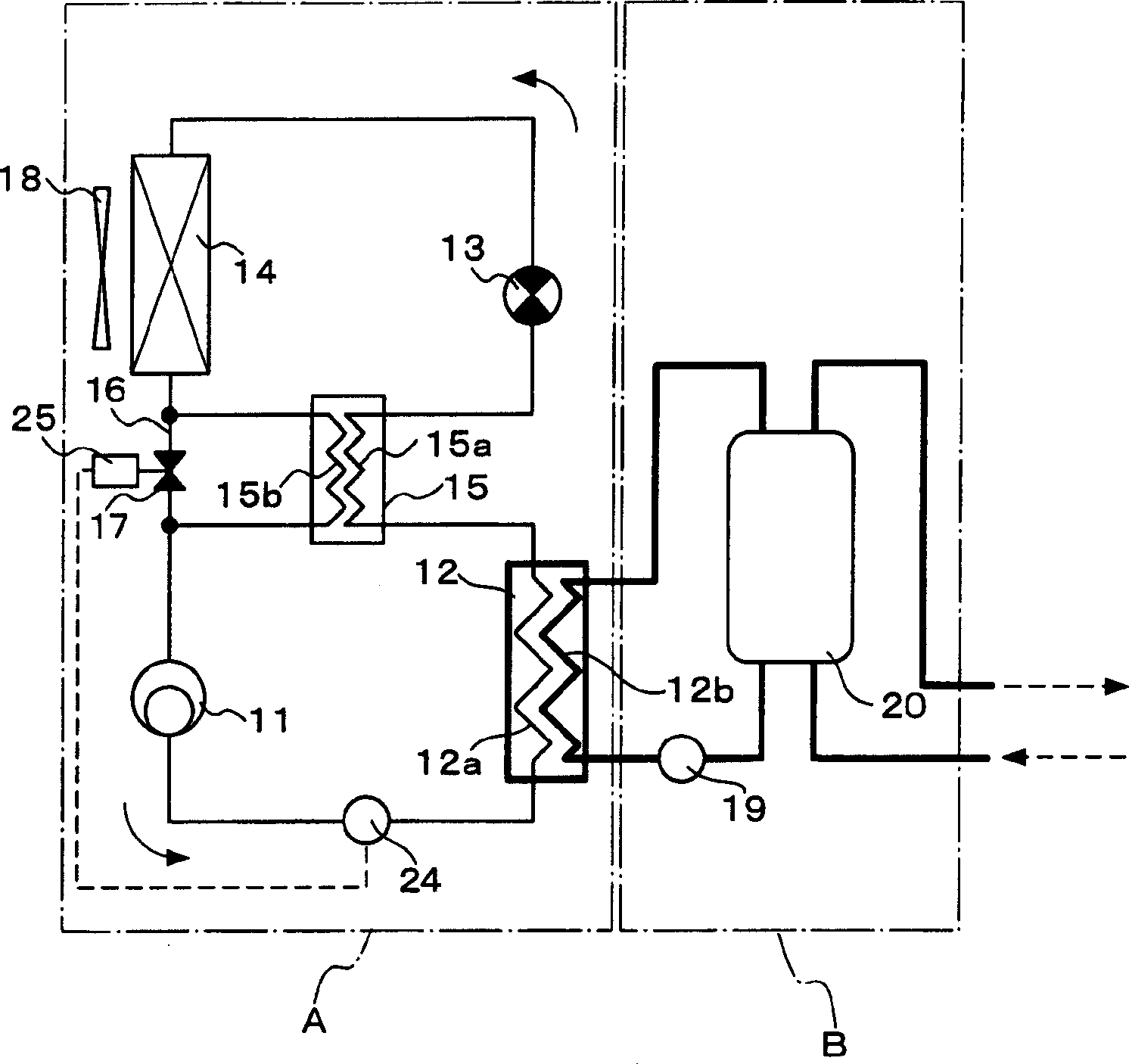

[0035] Hereinafter, a refrigeration cycle apparatus according to an embodiment of the present invention will be described by taking a hot water supplier as an example with reference to the drawings. The present invention is not limited by this embodiment. figure 1 It is a configuration diagram showing the refrigeration cycle apparatus according to the first embodiment of the present invention.

[0036] The refrigeration cycle apparatus of the first embodiment includes a refrigerant circuit A and a fluid circuit B; the refrigerant circuit A includes a compressor 11, a refrigerant flow path 12a of a radiator 12 as a heat exchanger for hot water supply, and an internal heat exchange circuit. The high-pressure side refrigerant flow path 15a of the unit 15, the pressure reducer 13, the evaporator 14, the low-pressure side refrigerant flow path 15b of the internal heat exchange unit 15, etc.; Road 12b, hot water supply tank 20, etc.

[0037]In the above-mentioned refrigerant circ...

Embodiment 2

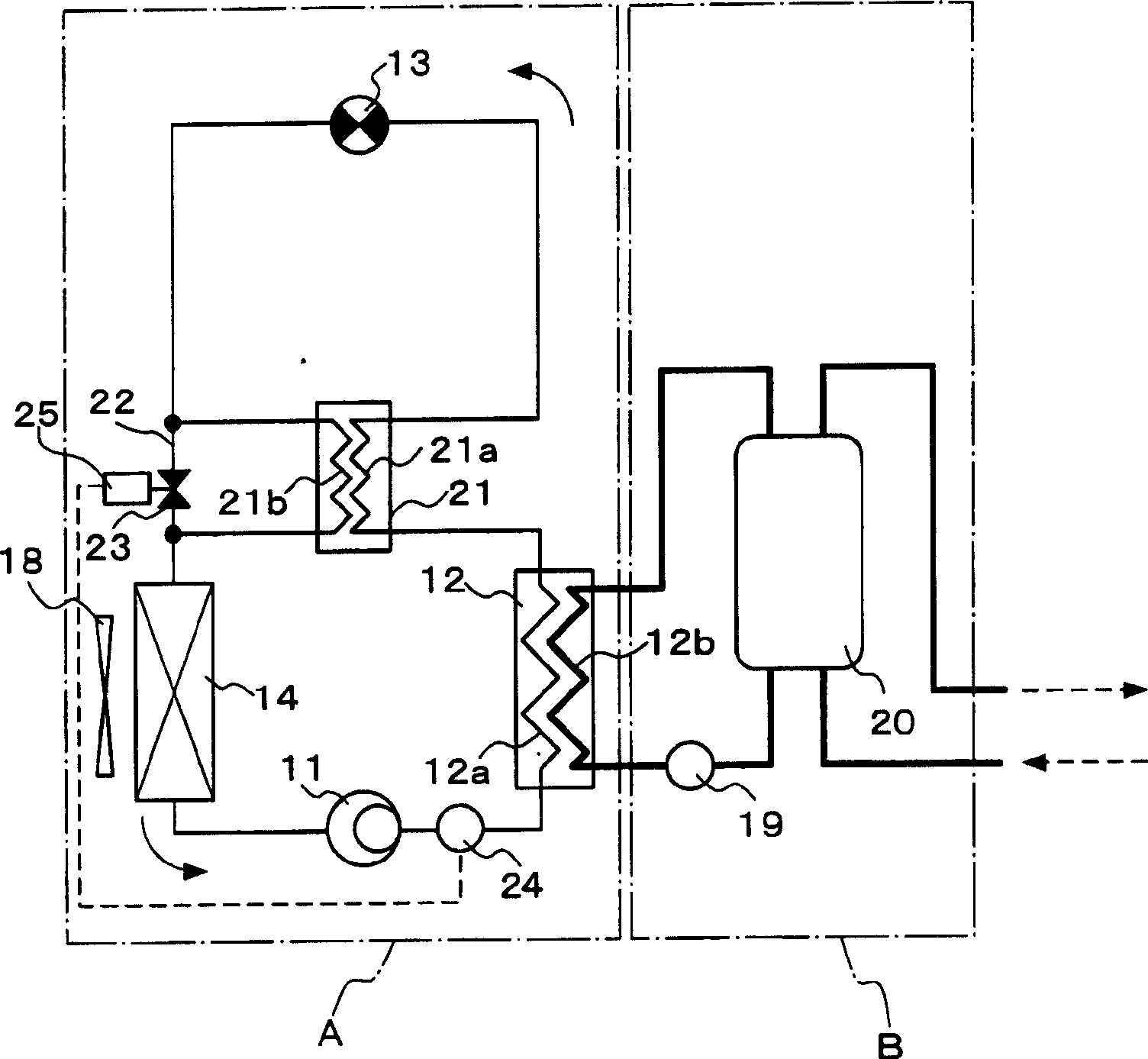

[0047] figure 2 It is a configuration diagram showing a refrigeration cycle apparatus according to a second embodiment of the present invention. In this embodiment, the same constituent elements as in the first embodiment are adopted and figure 1 The same symbols are used and their descriptions are omitted, and the configuration and operation different from those of the first embodiment of this embodiment will be described below.

[0048] In the refrigeration cycle apparatus of the second embodiment, the high-pressure side refrigerant flow path 21a of the internal heat exchange unit 21 is provided between the radiator 12 (refrigerant flow path 12a) outlet and the pressure reducer 13 inlet, and the low-pressure side refrigerant The flow path 21b is provided between the outlet of the decompressor 13 and the inlet of the evaporator 14, and is cooled in the radiator 12 by the low-pressure side refrigerant flowing in the low-pressure side refrigerant flow path 21b between the out...

Embodiment 3

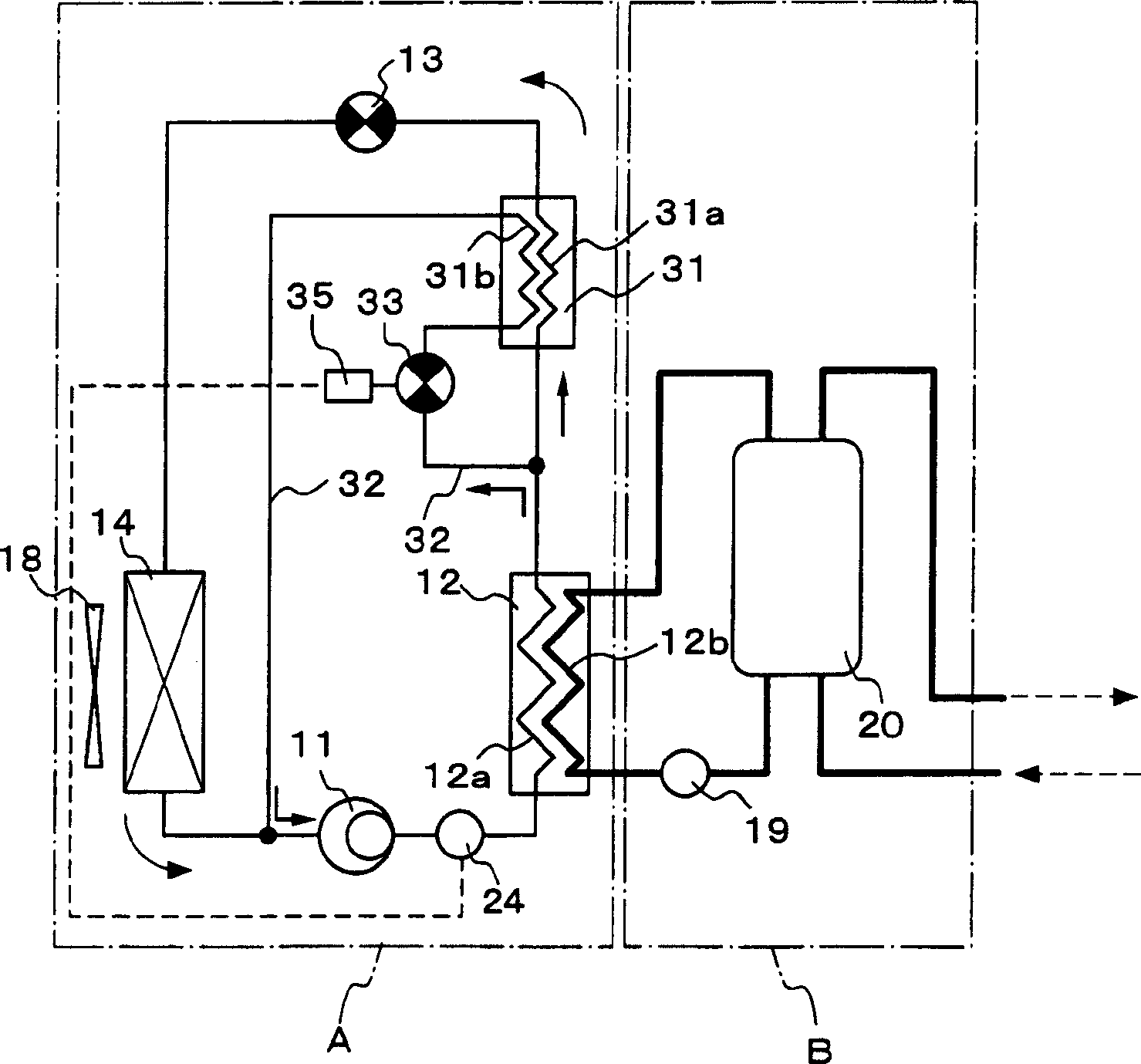

[0055] image 3 It is a configuration diagram showing a refrigeration cycle apparatus according to a third embodiment of the present invention. In this embodiment, the same constituent elements as in the first embodiment are adopted and figure 1 The same symbols are used and their descriptions are omitted, and the configuration and operation different from those of the first embodiment of this embodiment will be described below.

[0056] In the refrigeration cycle apparatus of the third embodiment, the high-pressure side refrigerant flow path 31a of the internal heat exchange unit 31 is provided between the outlet of the radiator 12 (refrigerant flow path 12a) and the inlet of the pressure reducer 13, and the low-pressure side refrigerant flow path The flow path 31b is provided in a bypass circuit 32 that branches between the radiator 12 (refrigerant flow path 12a) and the high-pressure side refrigerant flow path 31a of the internal heat exchange unit 31, and passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com