Structure for positioning umbrella stick

A technology for positioning structures and umbrella ribs, applied in the direction of walking sticks, etc., can solve problems such as decoupling and falling of the pivotal hook part 98, quality loss, unstable holding and swinging of umbrellas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

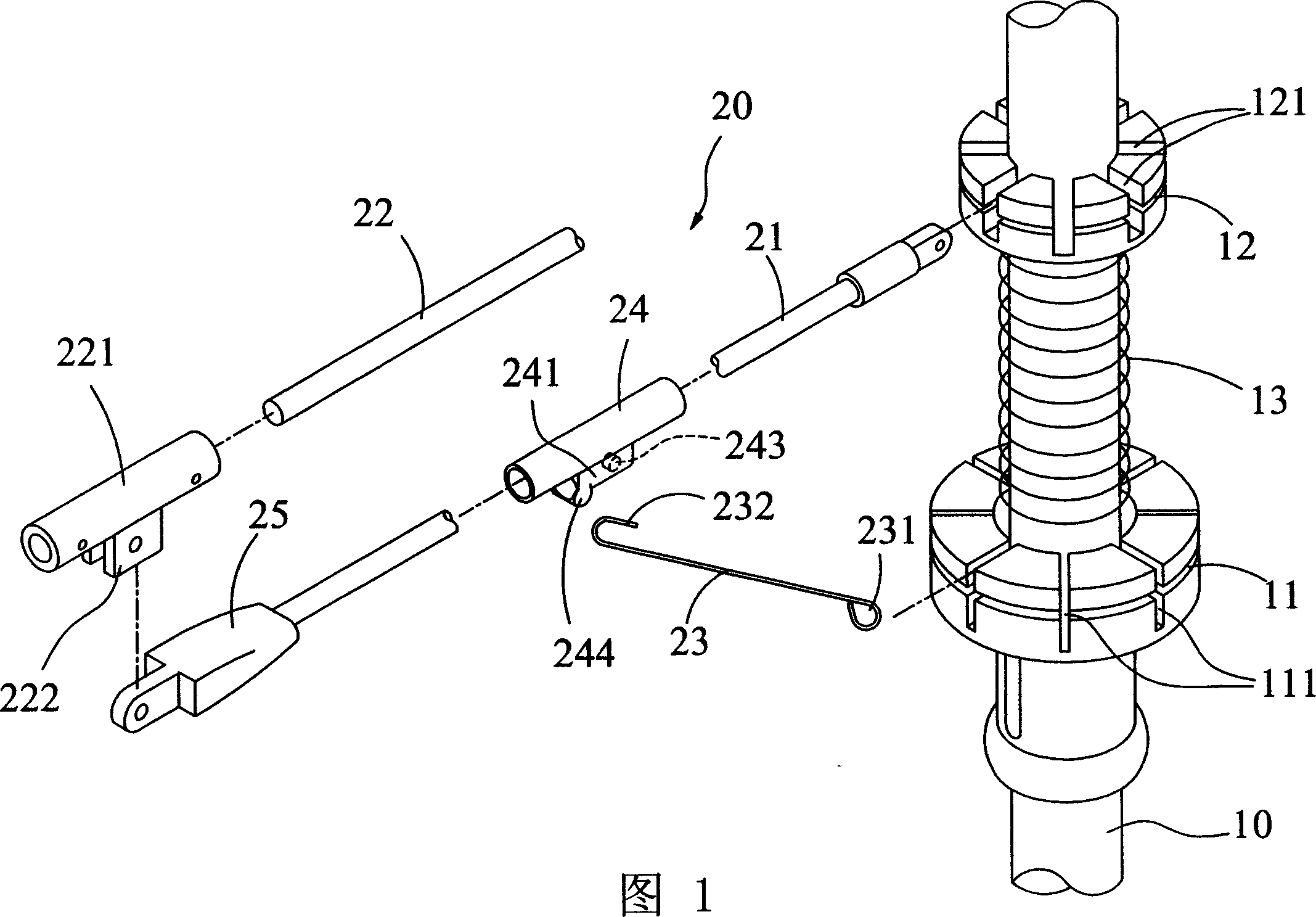

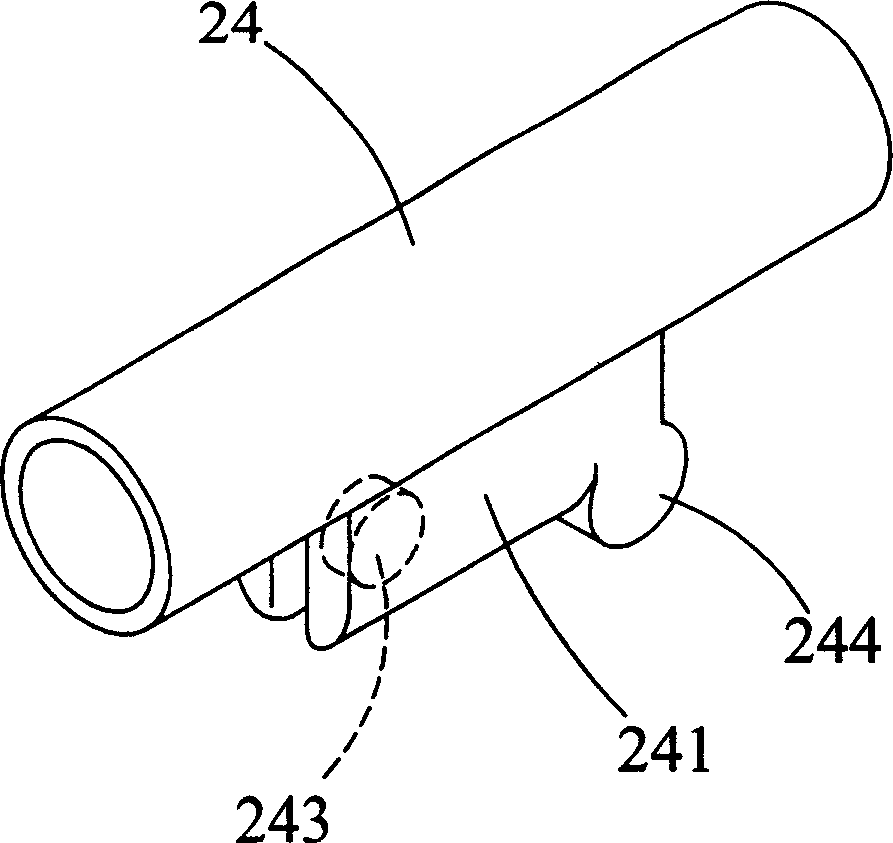

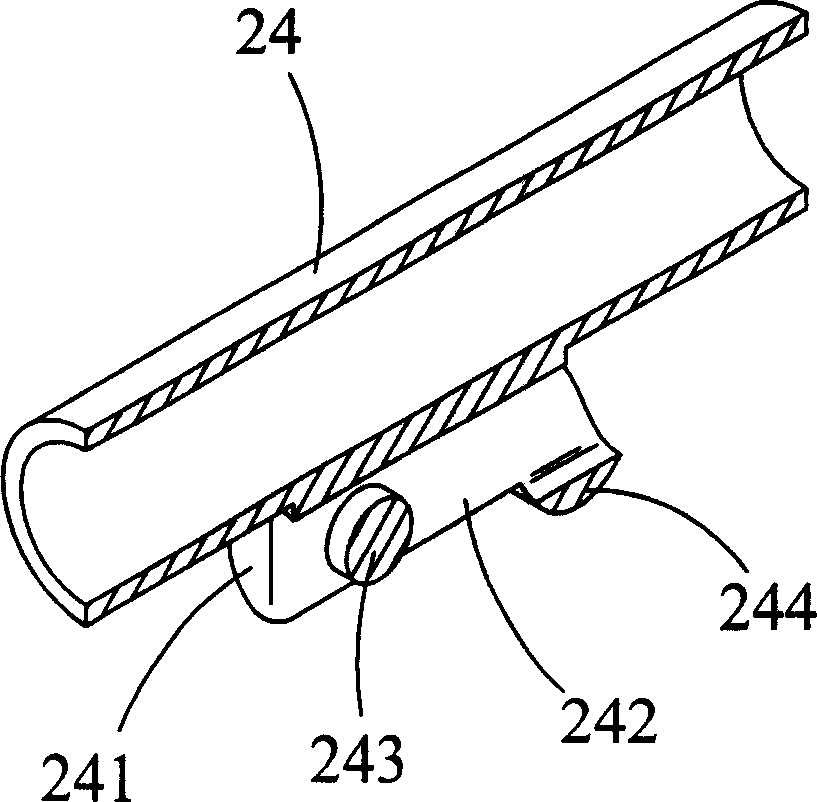

[0022] As shown in Figures 1 to 5, the umbrella rib positioning structure of the present invention includes a main shaft 10 and an umbrella rib mechanism 20, and a first nest 11 and a second nest 12 are pivotally arranged on the main shaft 10. The first nest body 11 and the second nest body 12 are respectively provided with a plurality of sockets 111, 121, and between the first nest body 11 and the second nest body 12 there is an extension spring 13 against it; the umbrella rib mechanism 20 is It includes a plurality of supporting ribs 21, a main rib 22 and a pull rod 23. The supporting ribs 21 are pivotally connected to the slot 121 of the second nest body 12, and a pivoting piece 24 and an end pivot are sleeved on it. Connecting member 25, wherein the bottom edge of the pivoting member 24 is provided with a lug 241, and the lug 241 has a perforation 242 and pivot pins 243 and stoppers 244 at both ends of the perforation 242 (such as image 3 shown); the main umbrella rib 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com