Air conditioner shell-and-tube condenser with built-in oil cooling device

An oil-cooled, shell-and-tube technology, used in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of inconvenient structural design and engineering installation of air-conditioning units, complicated layout of related pipelines, etc., and simplify equipment configuration. , The effect of reducing product cost and facilitating engineering installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

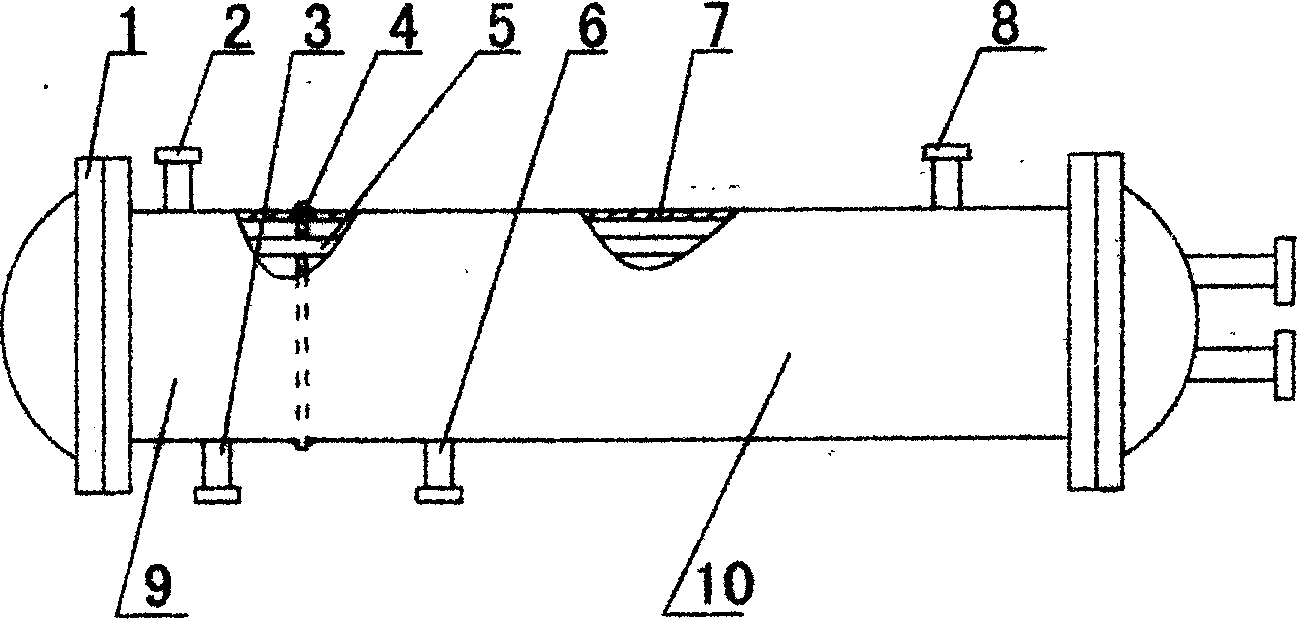

[0008] Such as figure 1 Shown, the present invention comprises oil cooling part (9) and condensing part (10), and oil cooling part and condensing part are connected in a cylinder (7), cut off with baffle plate (4) in the middle, the radiating pipe ( 5) Pass through the baffle and fix on the tube plates (1) at both ends, the compressor oil enters from the oil inlet pipe (2) and comes out from the oil outlet pipe (3), and the refrigerant enters from the refrigerant inlet pipe (8). Out of the refrigerant outlet pipe (6), the cooling water in the heat dissipation pipe cools the compressor oil while cooling the refrigerant, realizing the unification of the condenser and the oil cooler.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap