Optical fiber grating template with long stress cycle and fabricating method thereof

A fiber grating and long-period technology, which is applied in the coupling of optical waveguides, electromagnetic wave transmission systems, electrical components, etc., can solve the problem of high mechanical production requirements, poor resonant peak tuning of long-period fiber gratings, and the difficulty of making flat plates with grooves. Easy and other problems, to achieve the effect of large tunability and simple experimental equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

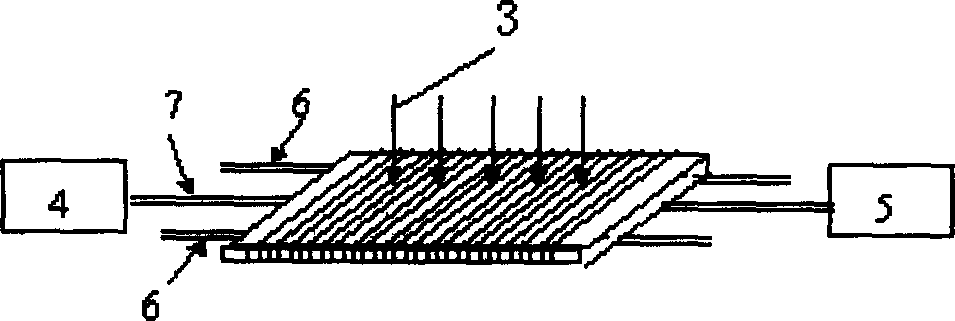

[0016] The present invention will be specifically described below in conjunction with the accompanying drawings.

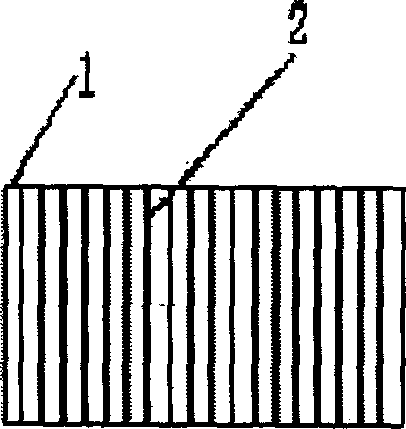

[0017] The template of this stress long-period optical fiber grating is characterized by: a rectangular plexiglass plate 1 with a periodic stripe pattern 2 on it, and copper wires are wound on the glass plate according to the stripe pattern.

[0018] The manufacturing method of this stress long-period fiber grating template is characterized in that it will go through the following steps:

[0019] 1) Process a plexiglass plate 1 earlier;

[0020] 1) Use the software Aotucad to make a rectangular stripe pattern 2 with periodic stripes, the size of the rectangle is the same as the size of one side of the plexiglass plate;

[0021] 2) Print and paste the rectangular stripe pattern on the plexiglass surface;

[0022] 3) Wind the copper wire on the glass plate according to the stripe pattern in the rectangle;

[0023] Specific processing steps: first process a plexig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com