Method for manufacturing multi-core long-period fiber gratings and fiber rotation positioning device

A multi-core optical fiber and fiber grating technology, applied in cladding optical fiber, optical waveguide and light guide, etc., can solve the problems that it is difficult to meet the production requirements of batch production and multi-grating period, and the variation of core refractive index is not uniform, so as to achieve the goal of production The process is easy to control, the quality of writing is improved, and the effect of simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

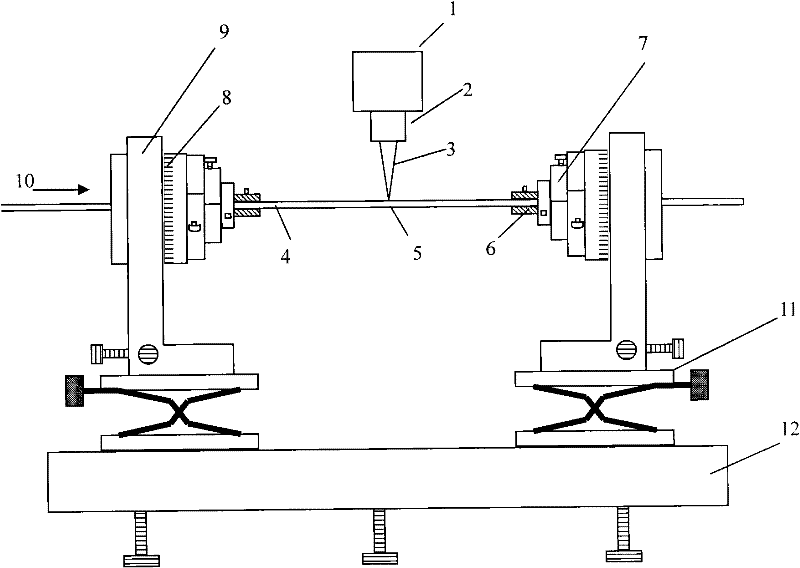

[0026] First calibrate the high frequency CO 2 Laser, and determine the parameters of the laser, such as operating frequency, duty cycle and release time, etc. The laser energy at the fiber exposure point 5 can be changed by adjusting parameters such as the frequency of the laser pulse and the Q release time. Secondly, design the resonant wavelength and loss peak size of the multi-core long-period fiber grating according to the actual production requirements, and determine the period and length of the grating.

[0027] Taking the fabrication of a four-core fiber long-period fiber grating as an example, the following steps are included:

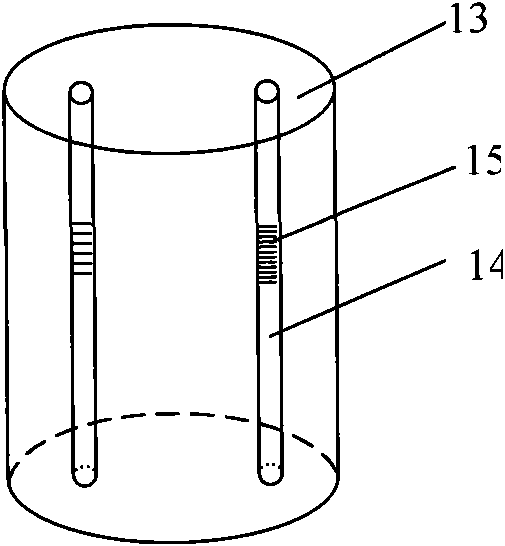

[0028] 1) Take a multi-core optical fiber 4, the optical fiber has four cores 14, and the four cores are symmetrically distributed on concentric circles, one section of which is stripped of the coating layer, which is about 50mm; use non-woven cloth dipped in alcohol and Diethyl ether mixture, repeatedly wipe the outer cladding 13 of the opt...

Embodiment approach 2

[0035] First calibrate the high frequency CO 2 Laser, and determine the parameters of the laser, such as operating frequency, duty cycle and release time, etc. The laser energy at the fiber exposure point 5 can be changed by adjusting parameters such as the frequency of the laser pulse and the Q release time. Secondly, design the resonant wavelength and loss peak size of the multi-core long-period fiber grating according to the actual production requirements, and determine the period and length of the grating.

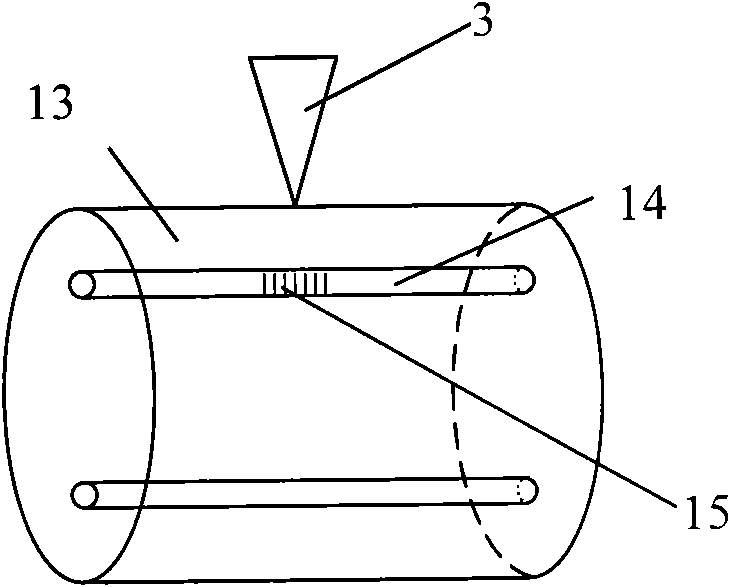

[0036] Taking the fabrication of double-period dual-core fiber long-period fiber grating as an example, the following steps are included:

[0037] 1) Get a multi-core optical fiber 4, the optical fiber has two cores 14, such as figure 2 As shown, one section of the coating layer is stripped, which is about 50 mm; use a non-woven cloth dipped in a mixture of alcohol and ether, repeatedly wipe the outer cladding 13 of the optical fiber, and fix it on the optical fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com