Friction clutch with intermediate plate mounting system

A technology for friction clutches and intermediate plates, applied in the direction of friction clutches, clutches, mechanically driven clutches, etc., can solve the problems of broken connecting transmission belts, complex structures, and increased manufacturing costs, so as to facilitate repair and replacement, prevent damage, and reduce manufacturing steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

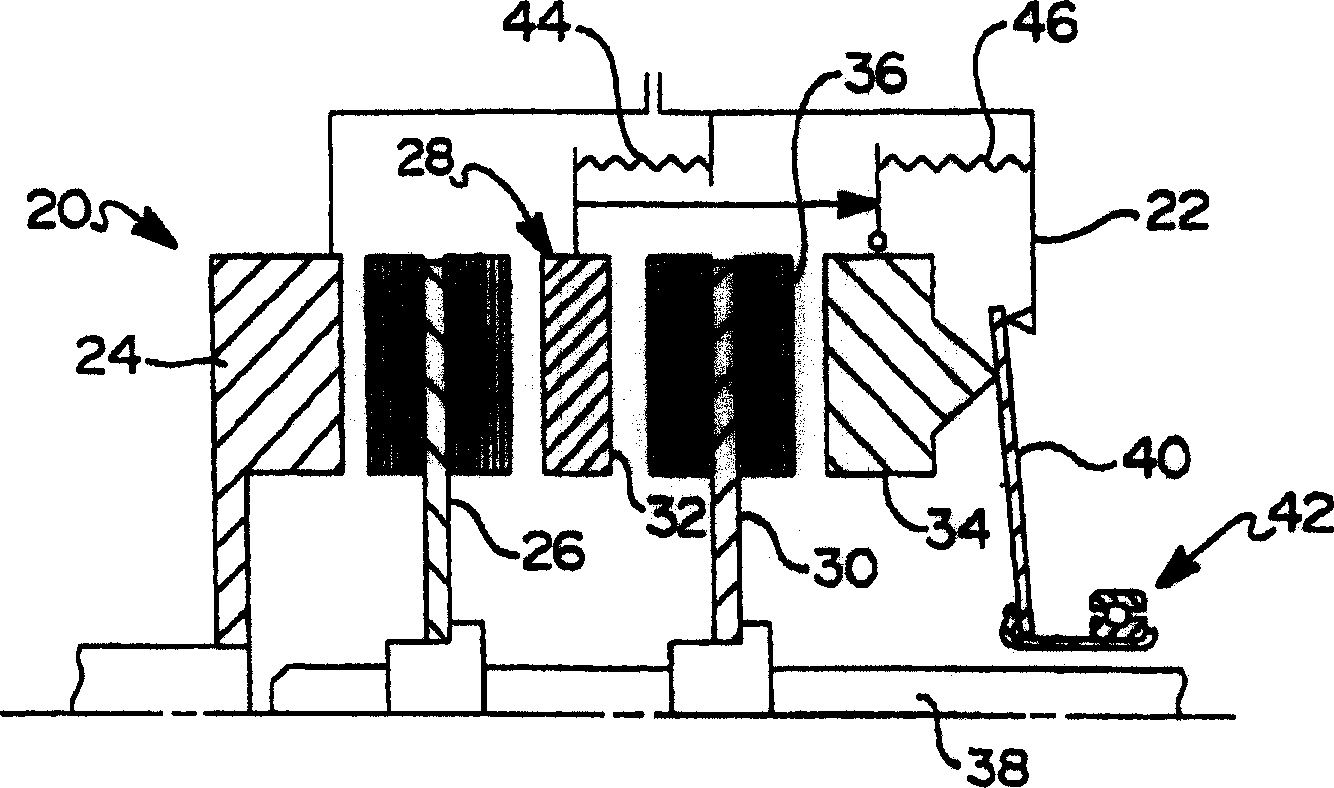

[0021] The accompanying drawings show in detail various preferred embodiments of the invention. figure 1 is a schematic diagram of a double disc friction clutch 20, and figure 2 is a partial sectional view of the clutch 20 . Clutch 20 includes a cover 22 removably mounted on a flywheel 24 of an internal combustion engine (not shown). Cover 22 houses a first friction disc 26 adjacent to flywheel 24 and an intermediate plate 28 adjacent to first friction disc 26 . A second friction disc 30 is adjacent to the transmission-facing side 32 of the intermediate plate 28 and a pressure plate 34 is adjacent to the transmission-facing side 36 of the second friction disc 30 . The first and second friction plates 26, 30 are fixed for rotation on a transmission input shaft 38, but are axially movable relative to each other.

[0022] The middle plate 28 and the pressure plate 34 are fixed to be rotatable together with the cover 22 and relatively movable in the axial direction like the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com