Carrier style hand sprayer

A sprayer, aircraft carrier-type technology, applied in the field of aircraft carrier-type hand-buckle sprayers, can solve the problems of insufficiency of liquid in the container, unreasonable design of the water dividing jacket, etc., and achieve the effects of increasing beauty, compact structure and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

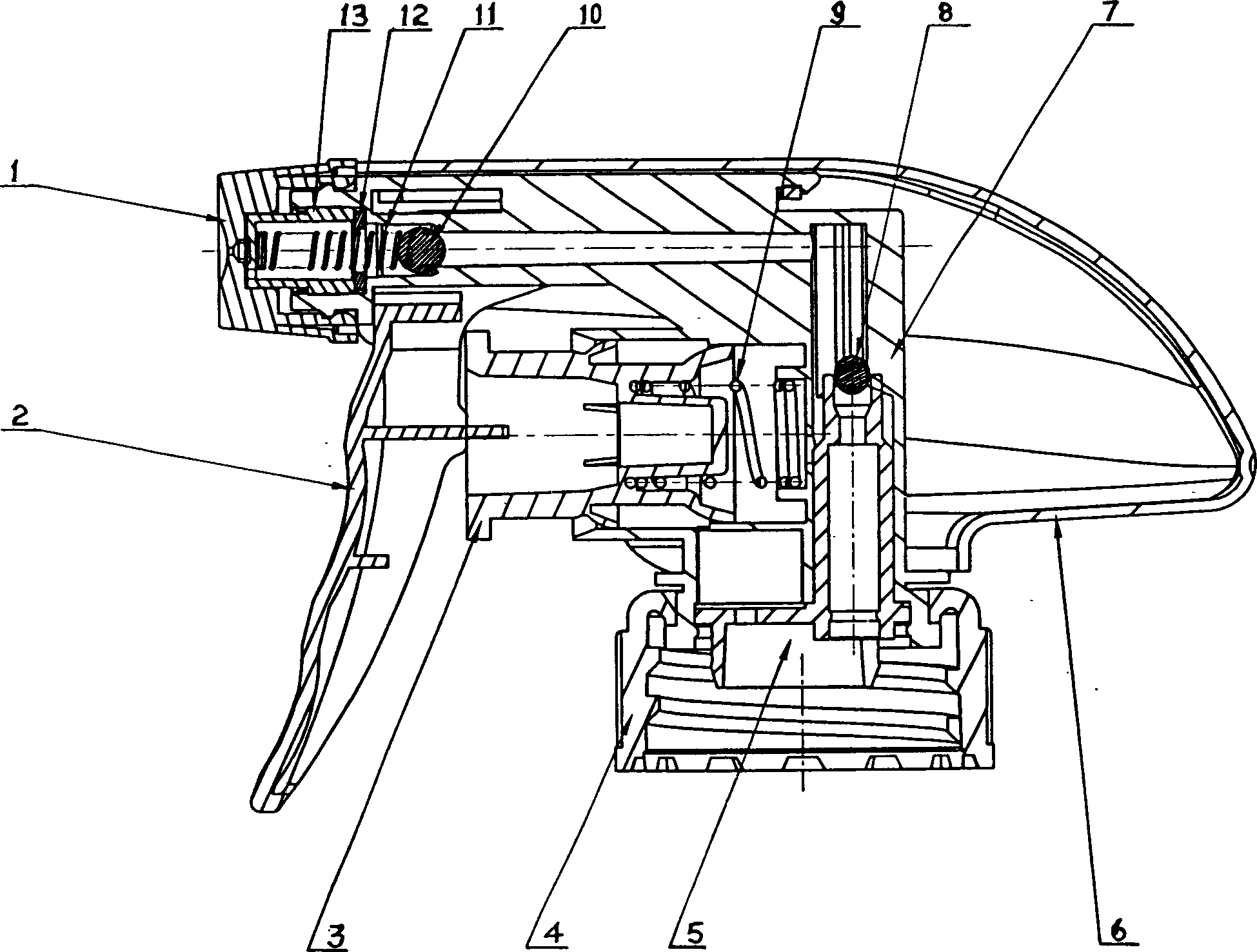

[0043] The implementation mode takes the installation and use of the present invention as an example. During installation earlier stuffy cover 5 is pressed on the main body 7, puts into glass ball 8 in vertical hole, then stuffy cover 5 is pressed, and cover plate 5-1 is pressed in the main cavity hole 7-5. Then put spring 9 and piston 3 into the main body transverse hole successively, and the pin post 7-1 of the main body is sheathed by the eyelet 2-1 of grasshopper type wrench 2. The fulcrum 2-2 of grasshopper type wrench withstands one end of piston. Insert glass ball 10, small spring 11, rubber sealing gasket 12, water-separating jacket 13 in the upper horizontal hole of main body 7 in sequence, and then press the multifunctional head cap 1 with the main body gun head 7-2. Aircraft carrier type casing 6 is inserted from left to right, because of the U-shaped groove is established at the top in the casing, the U-shaped groove is hooked and positioned by the hook tongue 7-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com