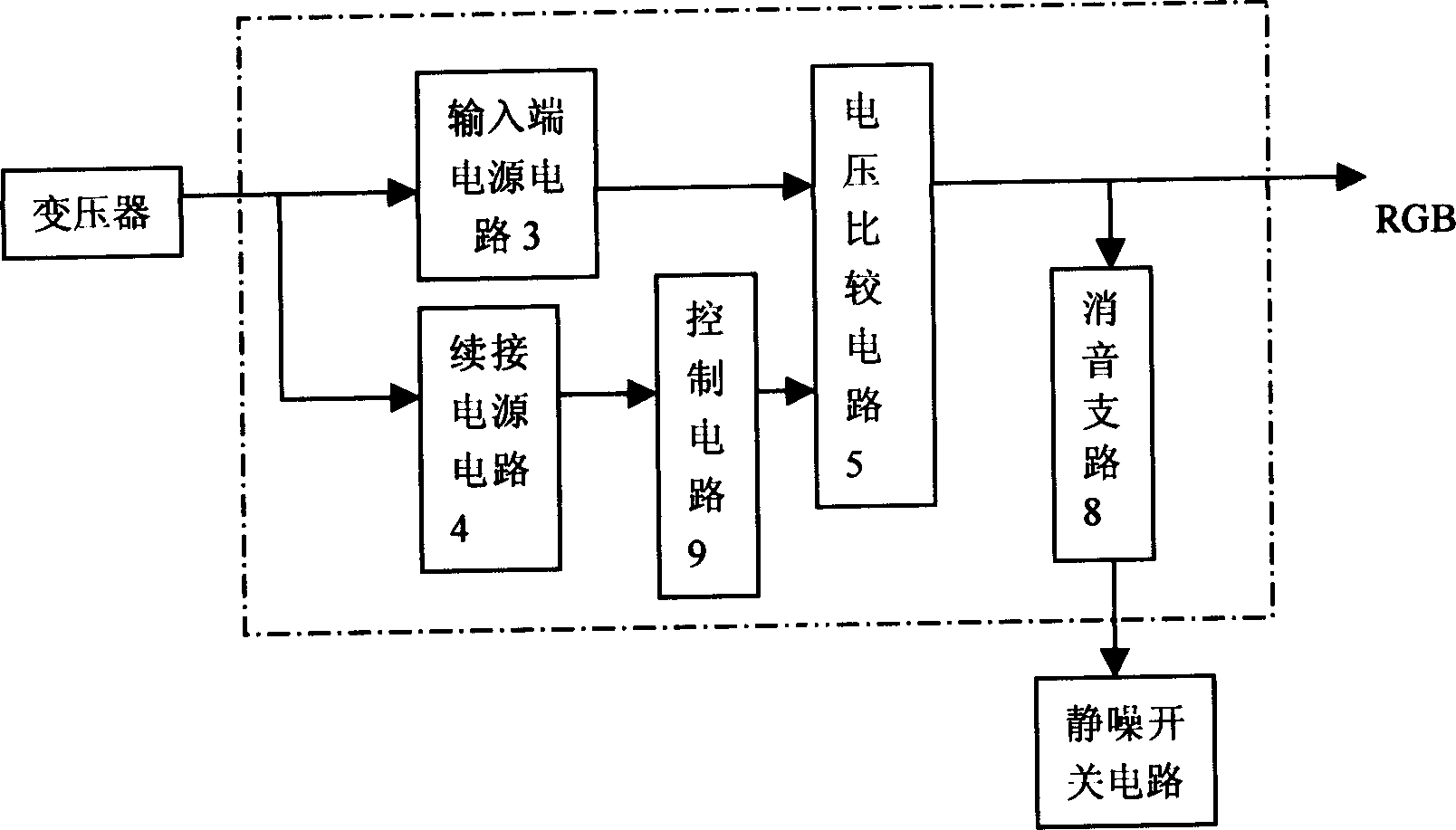

Turning-off delay circuit for video apparatus

A technology for video equipment and shutdown delay, which is used in TVs, electrical components, color TVs, etc., to achieve the effects of low cost, extended service life and simple circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

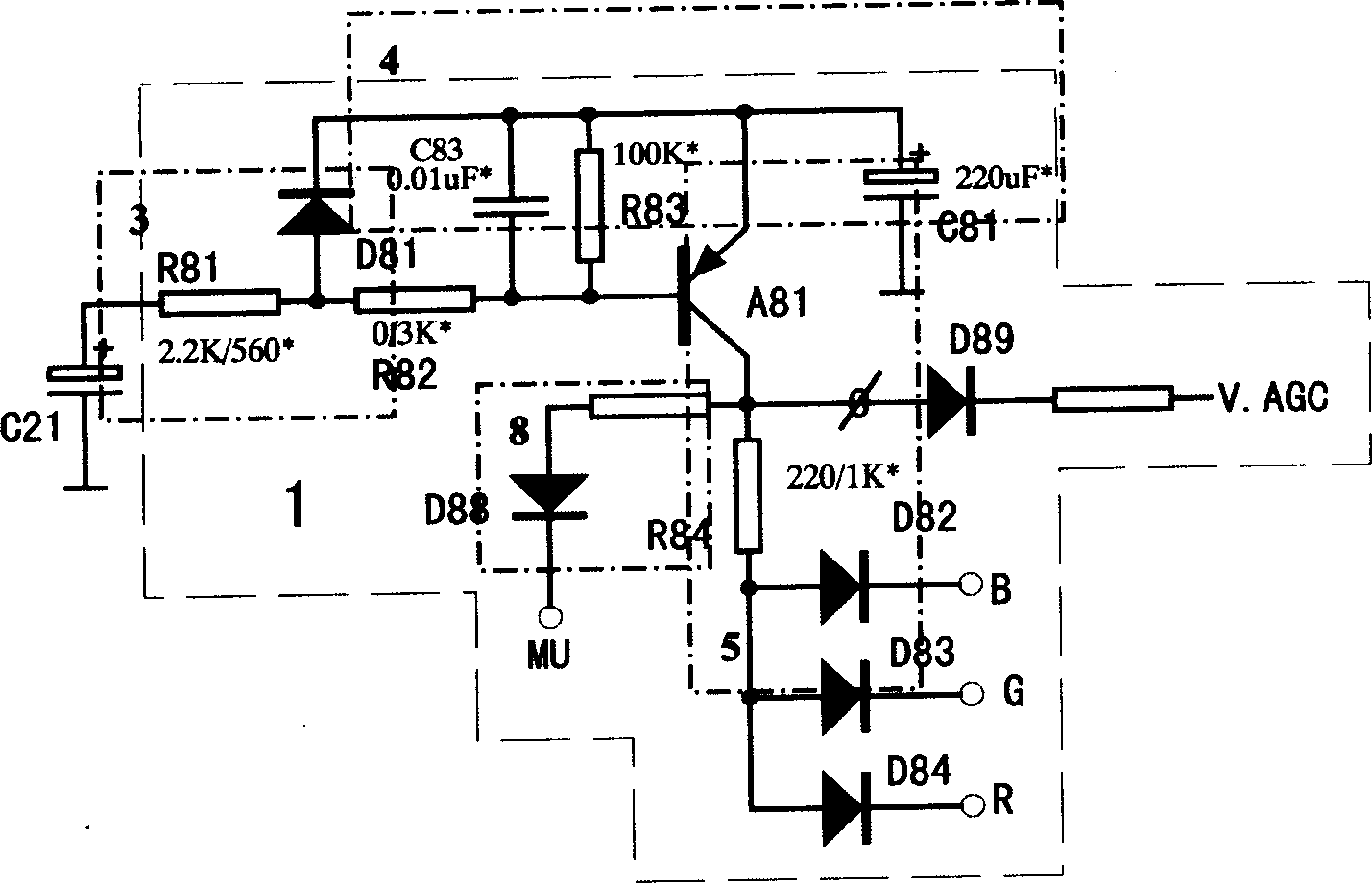

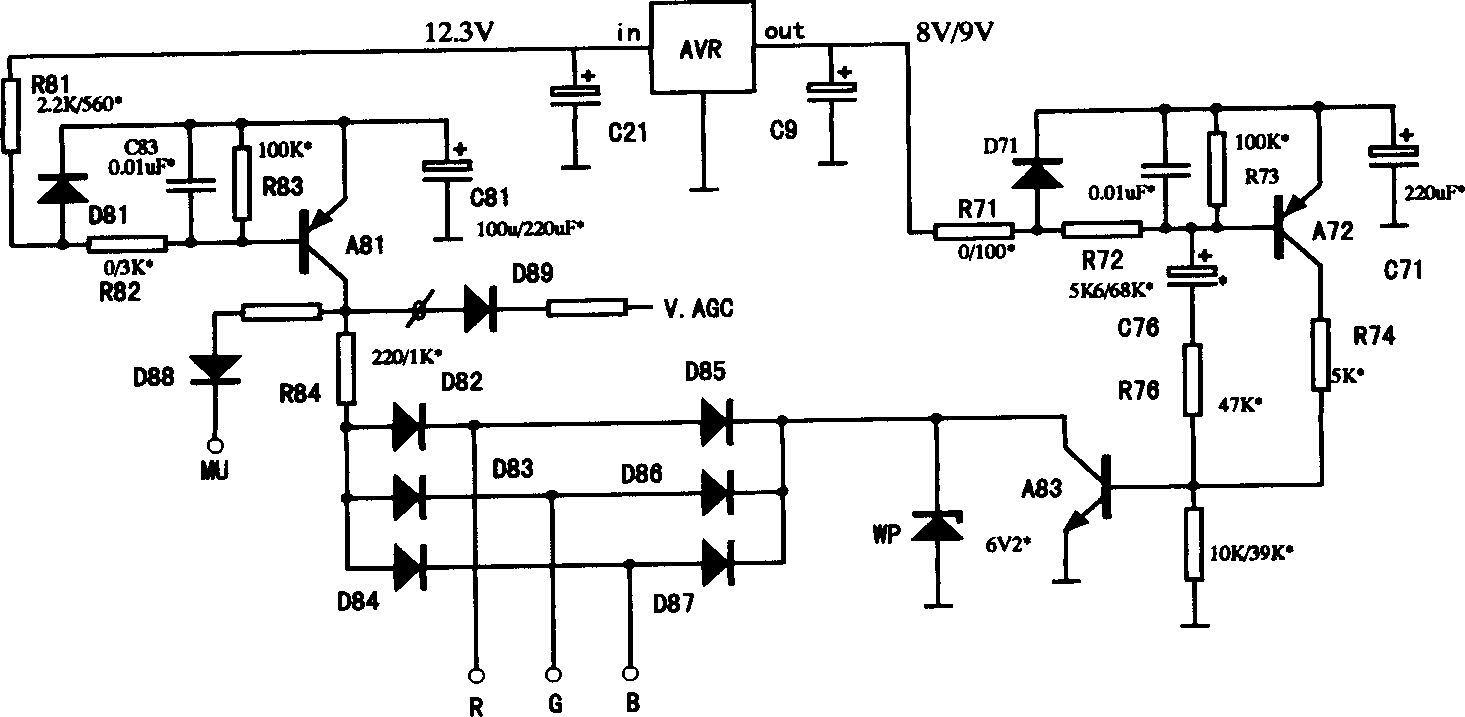

[0032] In order to further illustrate the implementation of the present invention, the technical solution is described in detail below in conjunction with the accompanying drawings:

[0033] Realize the general scheme of the present invention is: in series amplification resistance adjustment type voltage stabilizer (AVR) input terminal in and output terminal out or get two groups of voltage sources that the source has voltage difference, can make picture tube CRT enter grating gradually after setting up power-off respectively The circuit 1 in the shrinking state and the power-off or row scanning start or pause can make the picture tube CRT enter the cut-off state circuit 2. See [ Figure 6 Example]. Added monostable kinescope CRT filament preheating circuit 2 for cut-off viewing, see Figure 7 or Figure 8 example. The circuit 1 that enters the gradually shrinking state of the white raster when the added picture tube is powered off figure 2 . The added circuit 1 that ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com