Diaphragm unit

一种隔膜、区域的技术,应用在隔膜单元领域,能够解决不均匀施加、未提到凸面区域和凹面区域的曲率半径、减少隔膜耐久性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

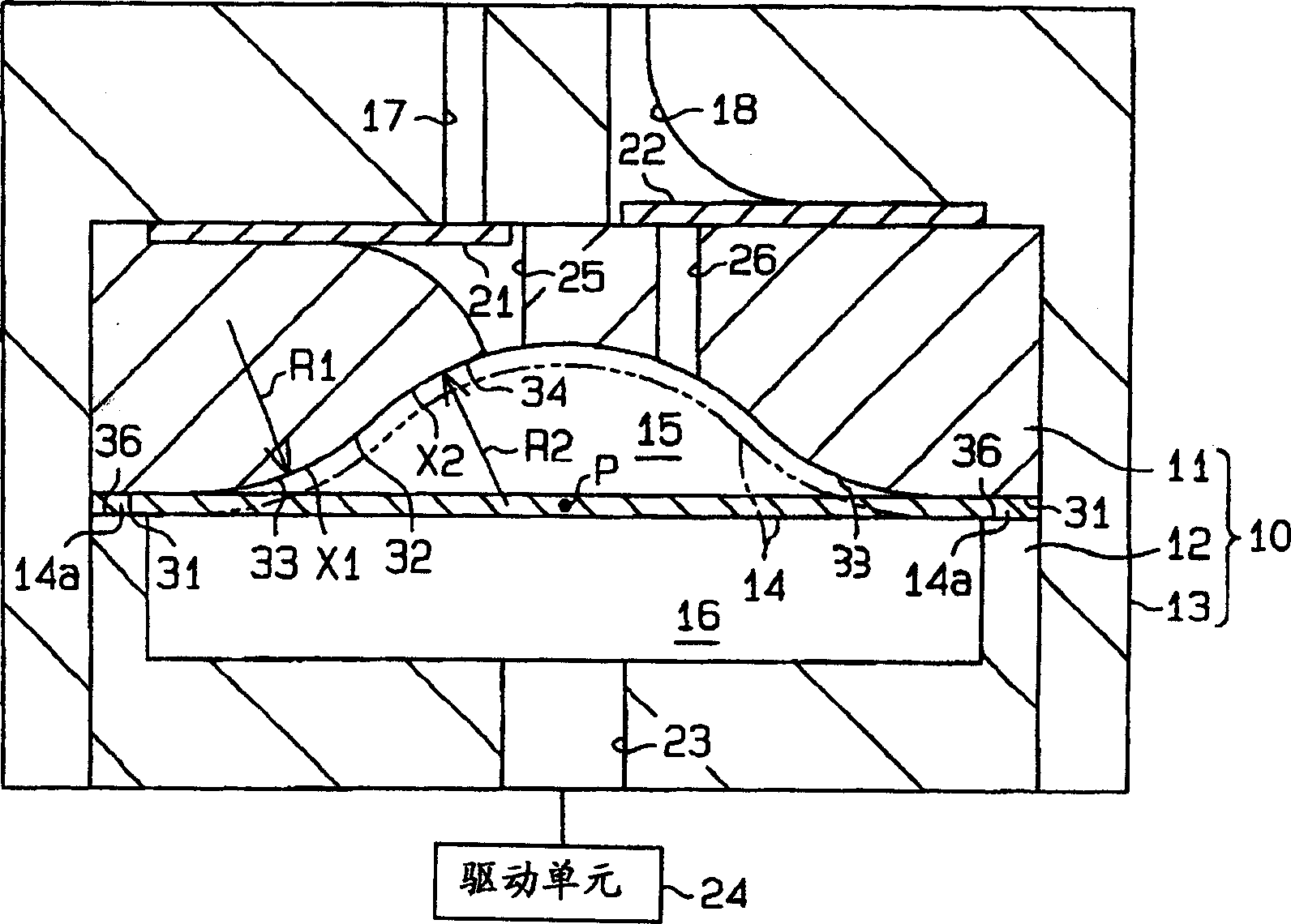

[0015] Below, based on figure 1 A diaphragm unit of a preferred embodiment of the present invention is described. The diaphragm unit in the example shown in this embodiment is used for a diaphragm pump suitable for air supply.

[0016] figure 1 A longitudinal sectional view of a diaphragm pump. Such as figure 1 As shown, the diaphragm pump has a diaphragm housing 10, the diaphragm housing 10 includes a first housing 11, a second housing 12 fixedly connected to the first housing 11, and a main body housing 13, the first housing 11 and The second case 12 is housed in the main body case 13 . Such as figure 1 As shown, the main body case 13 is formed in a cylindrical cover shape with a cover portion at the upper portion. The first and second housings 11 and 12 are accommodated in the main body housing 13 such that the first housing 11 is on the cover side.

[0017] The first housing 11 and the second housing 12 define a space therebetween, and this space is divided into a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com