Method of knitting knit-wear

A technology of knitted fabrics and needle beds, applied in the field of knitting with wide necklines, can solve the problems of unsightly appearance and poor fashionability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

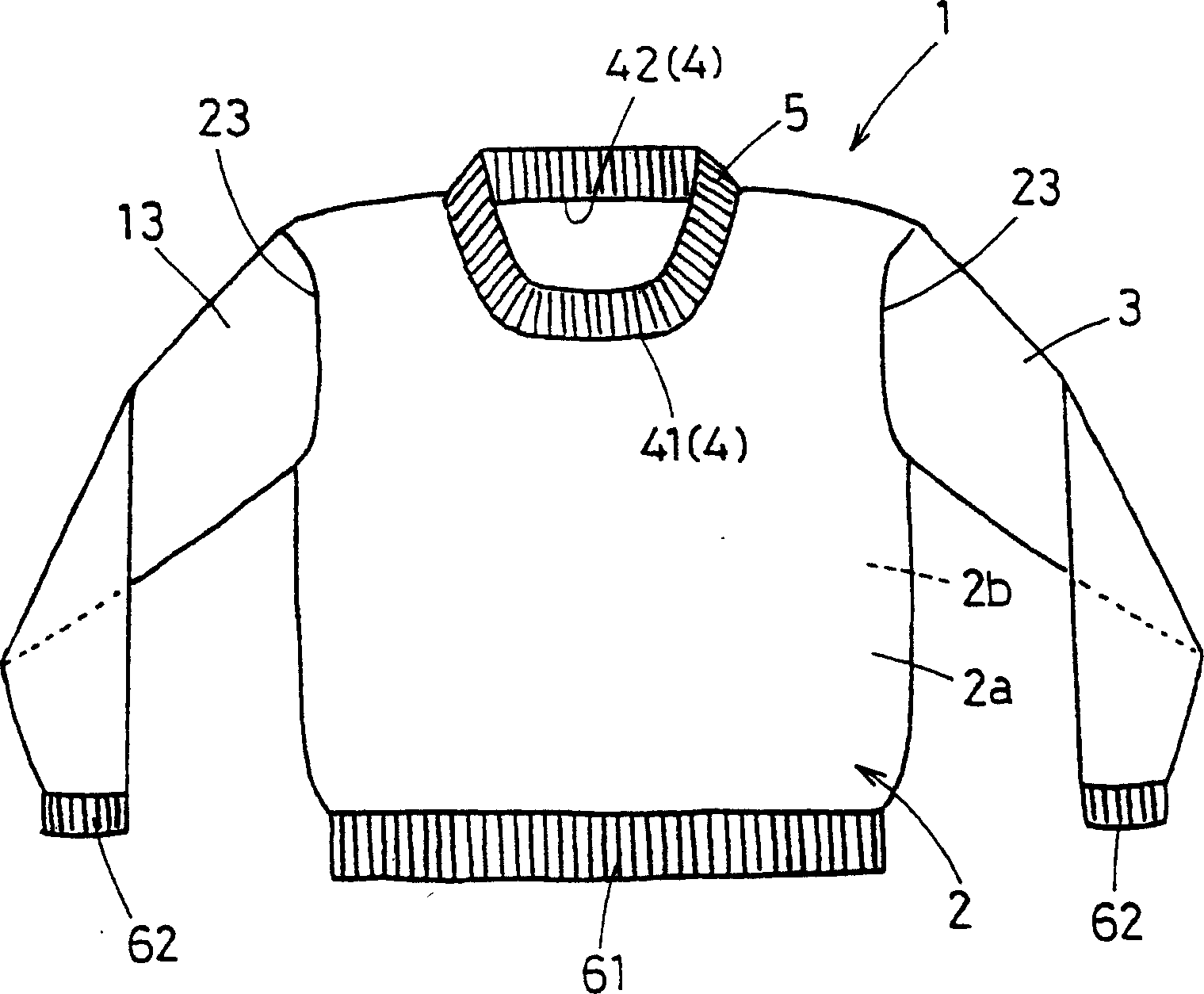

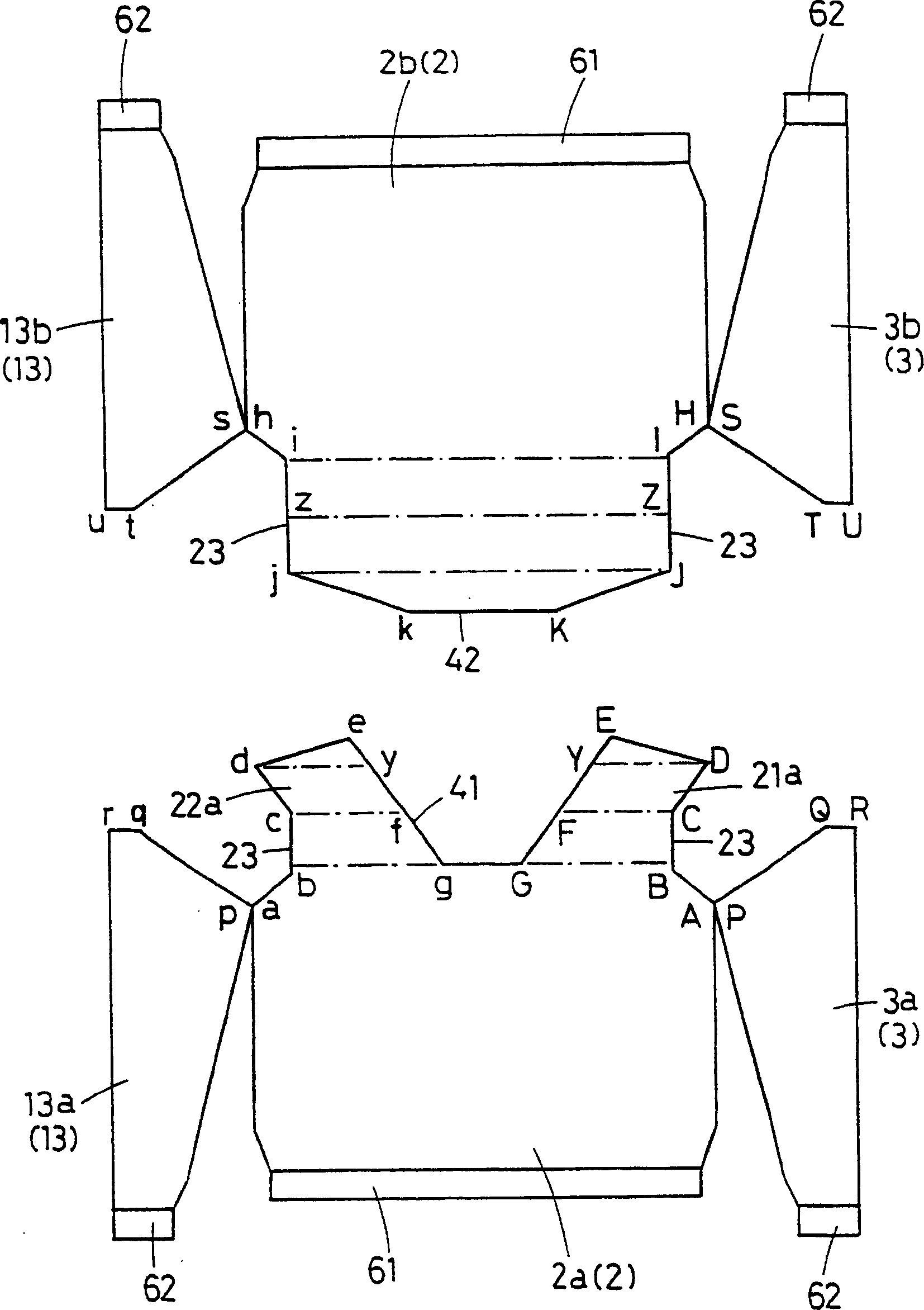

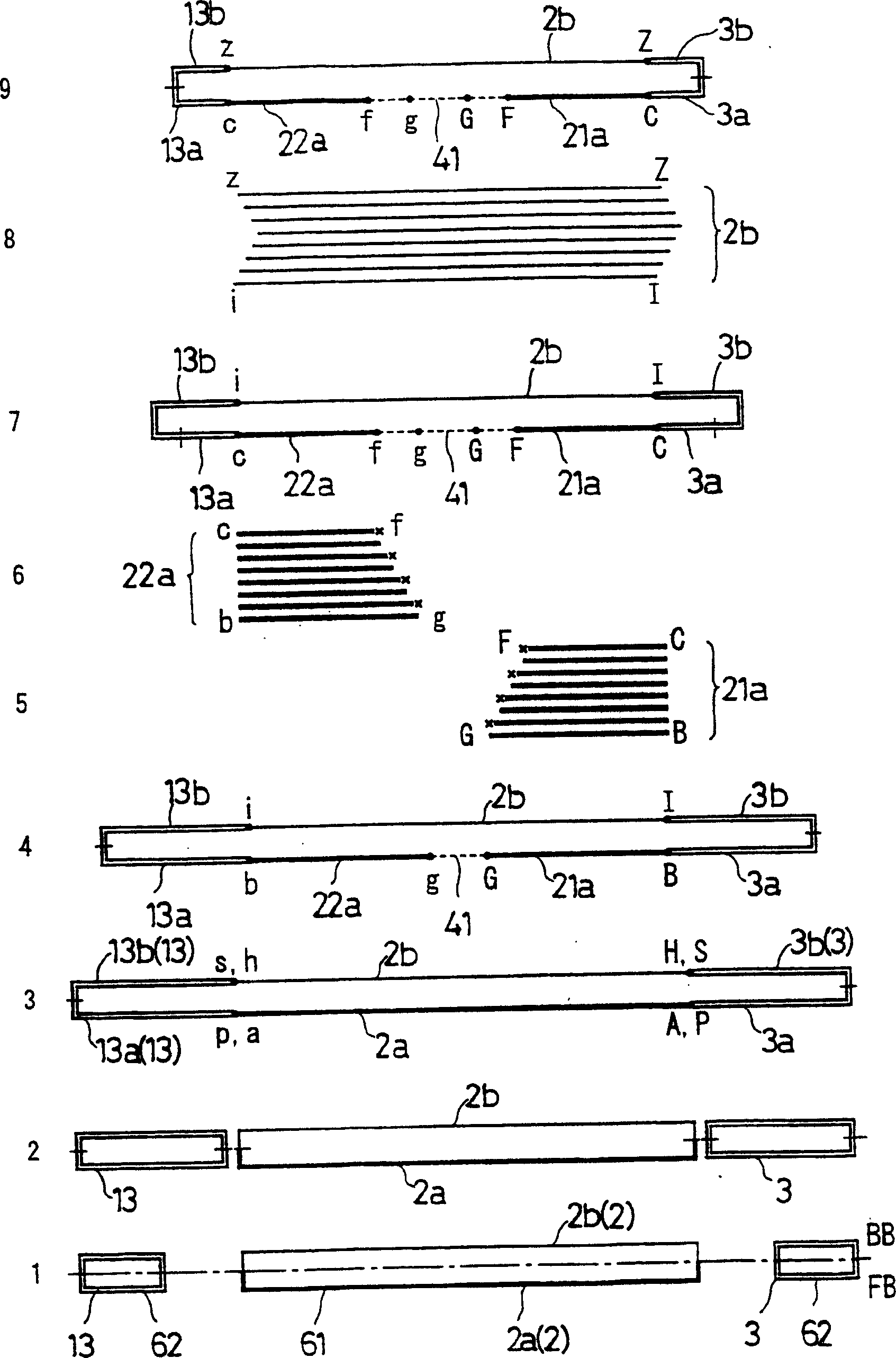

[0033] Hereinafter, an embodiment of the knitting method of the knitted fabric of the present invention will be described with reference to the drawings.

[0034] In this embodiment, two needle beds are used that have a pair of front and rear needle beds that extend in the left and right directions and face each other in the front and rear directions, and that the rear needle beds can be twisted to the left and right, and stitches can be transferred between the front and rear needle beds. Flat-knitting knitted fabric for the bottom panel.

[0035] A flat knitting machine with two base plates, when knitting tubular knitted fabrics, use a single knitting needle on the front and rear needle beds to knit, for example, the odd-numbered knitting needles on the front needle bed are mainly used to knit the front body The front part of the knitted fabric such as the front part of the piece or the sleeve is knitted, and the even-numbered knitting needles of the rear needle bed are mainl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com