Pivoting electromagnetic actuator and integrated actuator and fluid flow control valve

A technology of fluid flow and actuators, which is applied in the direction of electromagnets, electromagnetic relays, and electromagnets with armatures, etc., and can solve the problems of actuators not having fast response time, wear, and shortening device life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

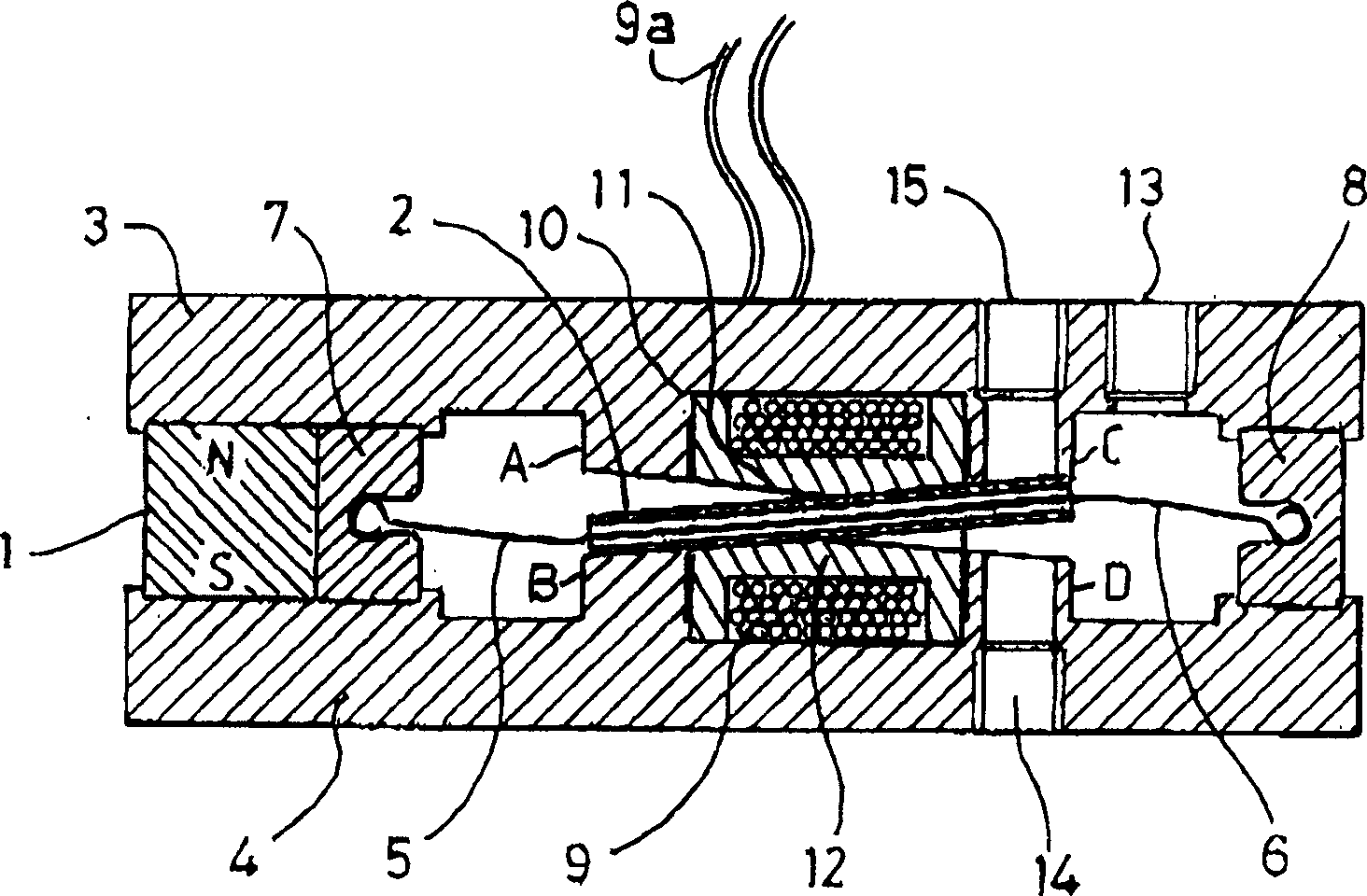

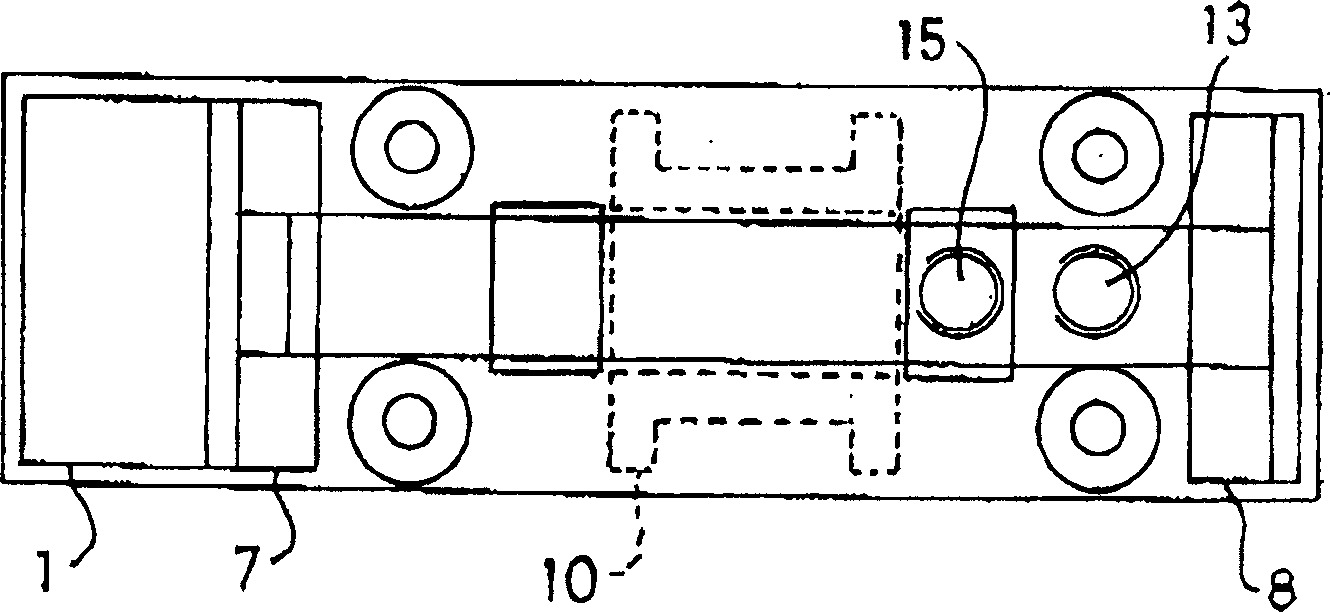

[0098] exist figure 1 and 2 Among them, the components are represented as follows: permanent magnet 1, swing armature 2, pole pieces 3, 4, springs 5, 6, spring holders 7, 8, coil 9, coil terminal 9a, coil body 10, swing edge 11, 12, entrance 13, exit 14, 15.

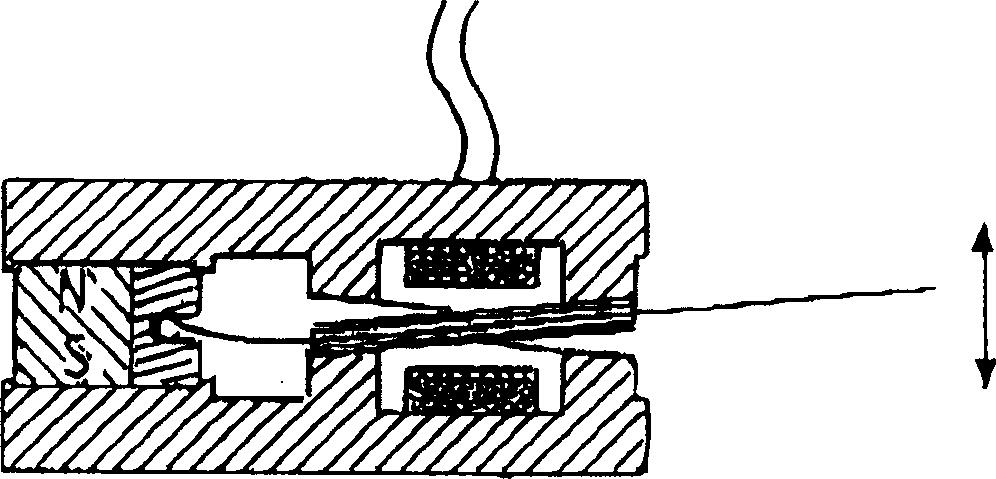

[0099] figure 1 The actuator represents a novel pulse-driven bistable device in which the movement of the ferromagnetic armature 2 is controlled by spring extensions 5, 6 anchored in two non-magnetic holders 7, 8 and formed in the coil body 10. The swinging edges 11, 12 are constrained in one plane. The armature will remain in one or the other of two steady state positions defined by poles A and D or B and C. The permanent magnet 1 provides the static magnetic flux and oscillates by changing the polarity of the armature and the balance between the magnetic flux connecting the poles and opposite ends of the armature.

[0100] This is achieved by a coil 9 mounted around the armature 2 which generates a local magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com