Method for producing all cotton non-woven fabric medical dressing

A technology of all-cotton non-woven fabric and production method, which is applied in the directions of application, non-woven fabric, textile and paper making, etc., can solve the problems of low qualified rate of finished product tension, high impurity content of finished product, high production cost, and improve cleanliness. , The effect of reducing scrap rate and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

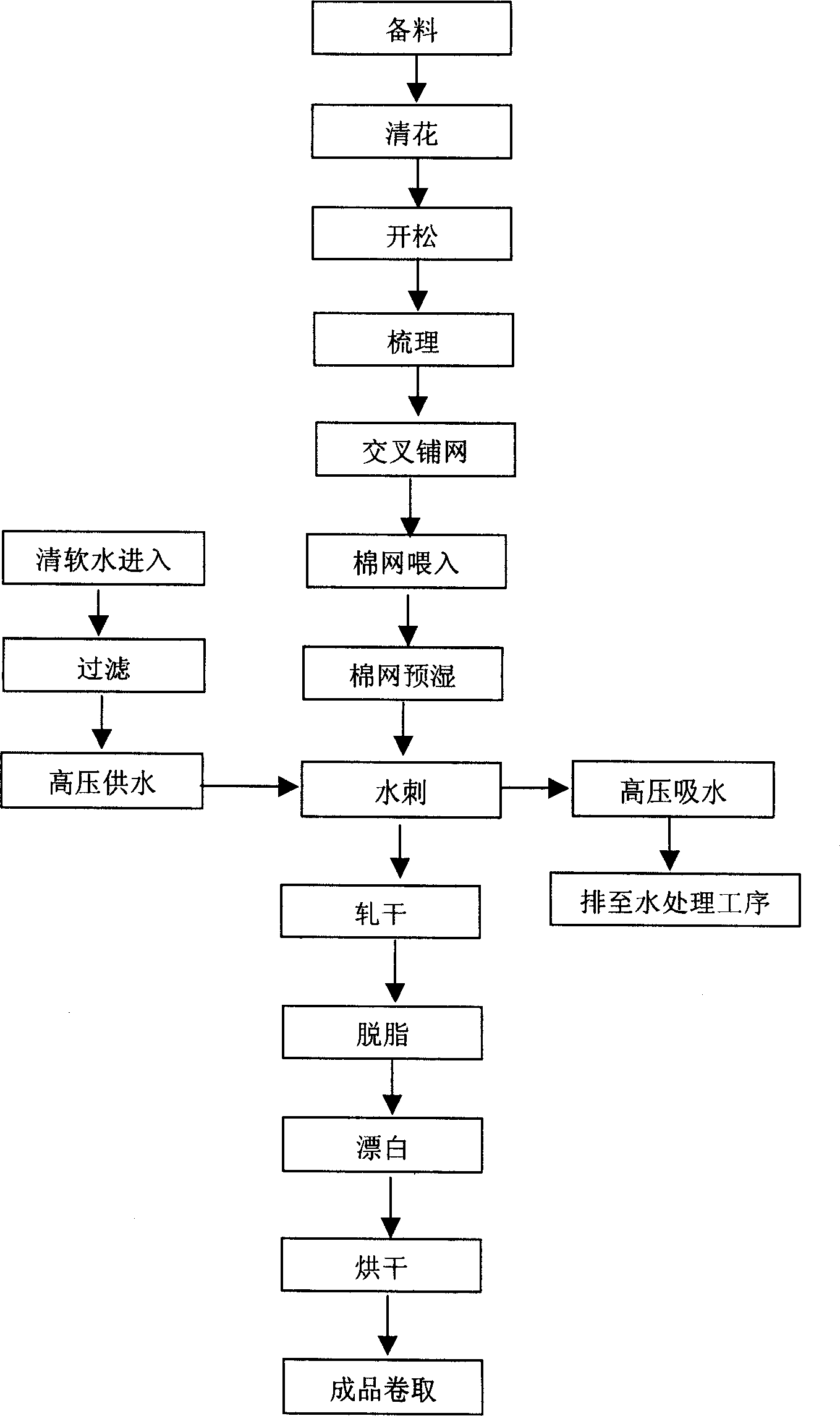

[0021] Such as figure 1 As shown, the production process of cotton non-woven medical dressing includes the following steps:

[0022] 1) Raw material preparation: the raw cotton, that is, 100% pure natural, undegreased and bleached lint-free cotton, is prepared for use;

[0023] 2) Blowing: First, the raw cotton is removed by a cleaning machine, and the three threads and foreign objects in the raw cotton, such as cotton leaves, etc., are screened out. This step is a known technology and is the same as the prior art;

[0024] 3) Carding: It includes two parts: opening and carding. Opening means using a carding machine to open the raw cotton after cleaning to form a single fiber state, which is necessary for removing small impurities and carding. Carding is to use a carding machine to comb the single fiber, and comb it according to the longitudinal direction of the raw cotton fiber, so that the tension between the fibers can be maximized. At the same time, the small impurities ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com