Angle variable rotor engine with a planet gear

A planetary gear and engine technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of difficult to achieve strict sealing, unable to realize the stroke cycle of four-stroke internal combustion engine, etc., and achieve good rotational balance performance and torque output characteristics. Improved, easy-to-manufacture results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The section "4 Description of the Drawings" has preliminarily described the specific implementation when explaining the structure and function of each part. This section further explains some details of the specific implementation.

[0039] 5.1 Parameter selection in specific implementation

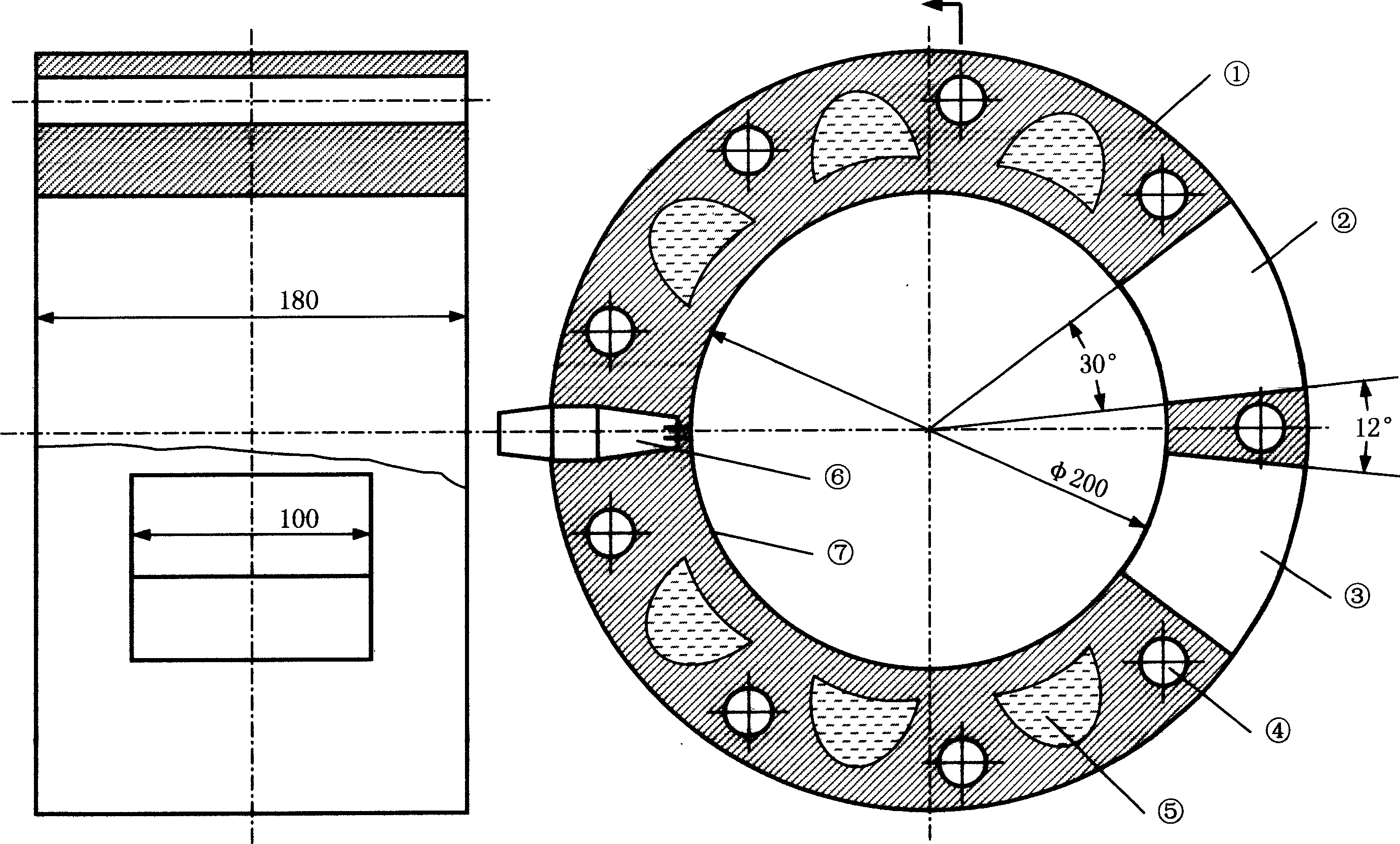

[0040] There are many options for the parameters in the specific implementation, the appended image 3 to attach Figure 7 The expressed scheme is selected based on the following parameters: the minimum included angle of the blades α=42°, the maximum included angle β=138°, the average angular thickness of the blades δ=30°, the design compression ratio K=(138°-30°) / (42° -30°)=9; the inner diameter of the cylinder is 200mm, the length of the vane along the axial direction of the cylinder is 120mm, and other parameters are as noted in the accompanying drawings.

[0041] 5.2 Assembly sequence

[0042] ① Two "U" shaped half-rotor buckles (the connecting shaft must be pre-installed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com