Electromagnetic buffer

A technology of electromagnetic buffers and buffers, applied in the direction of shock absorbers, shock absorbers, magnetic springs, etc., can solve the problems of increasing the machining process of electromagnetic buffers, motor damage, productivity and production cost effects, and improve processing performance. and productivity, reduced installation parts, and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

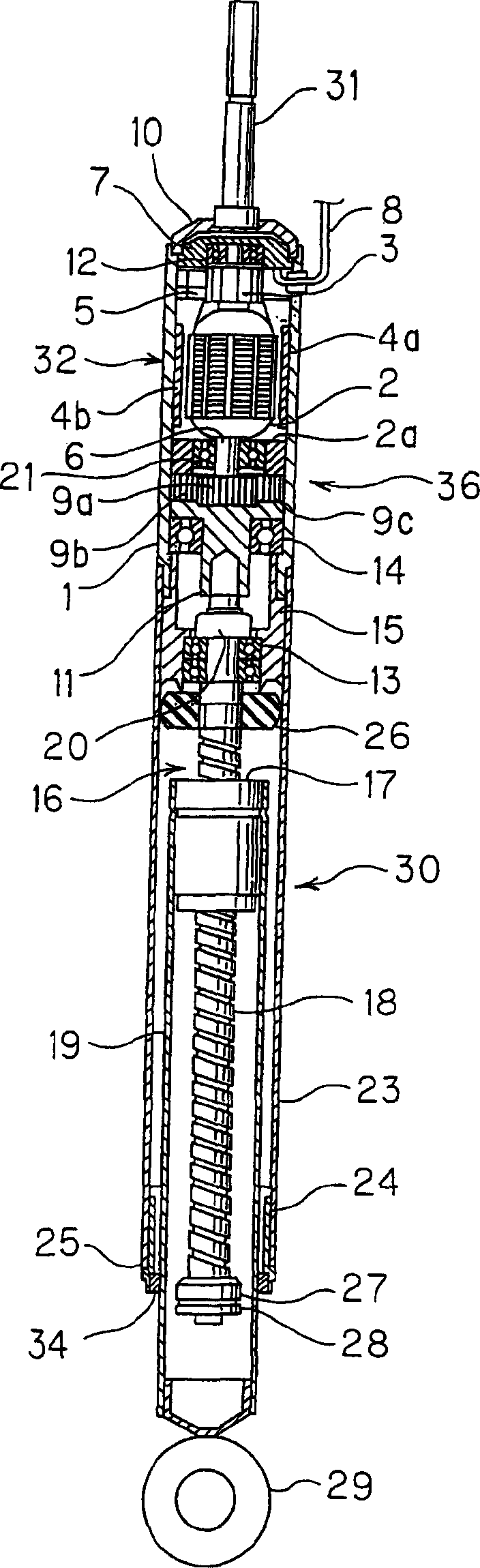

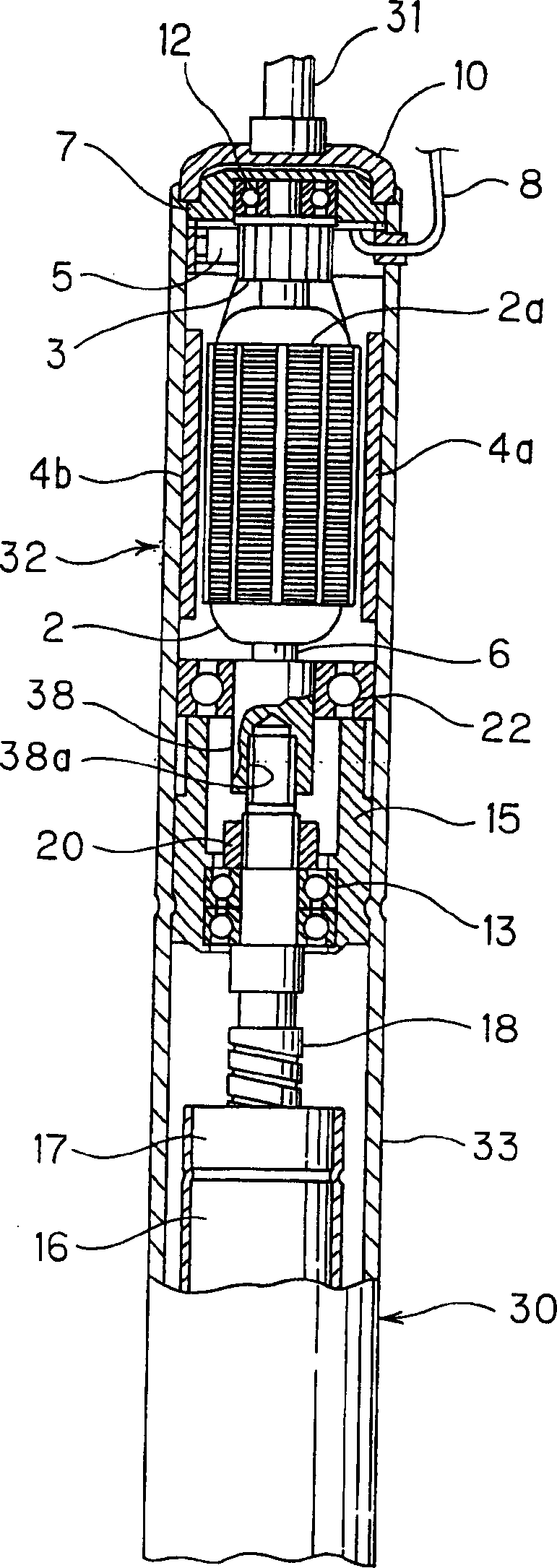

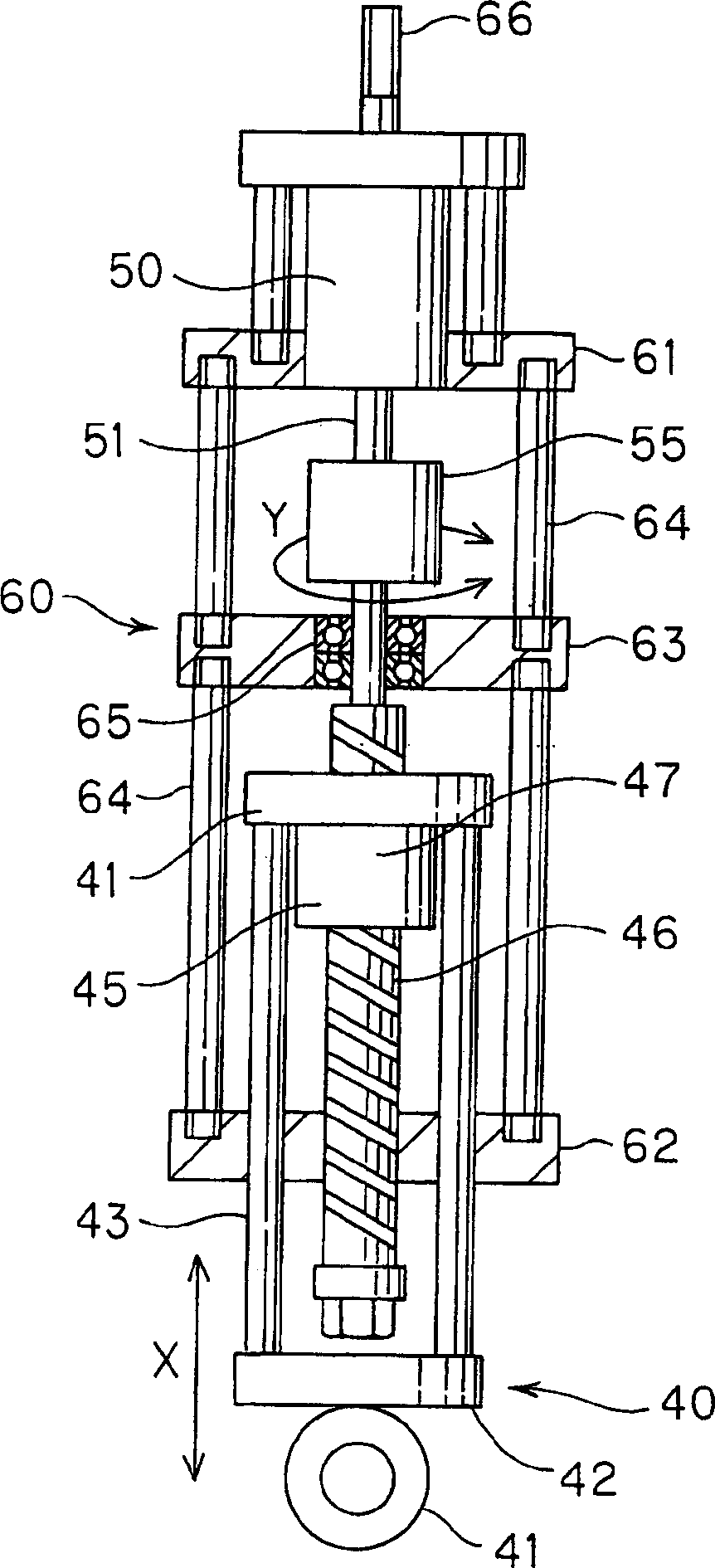

[0037] Next, the present invention will be described based on the embodiments shown in the drawings.

[0038] The damper main body 30 constituting the electromagnetic damper of the present invention includes an outer cylinder 23 into which an inner cylinder 19 is slidably coaxially inserted.

[0039] The motor 32 is arranged above the outer cylinder 23, and the screw shaft 18 constituting the ball screw mechanism 16 is arranged inside the inner cylinder 19, and the ball nut 17 screwed with the screw shaft 18 is fixed to the upper part of the inner cylinder 19. When the inner cylinder 19 expands and contracts relative to the outer cylinder 23 , the screw shaft 18 screwed to the ball nut 17 rotates at this position.

[0040] The shaft 6 of the motor 32 is connected to the screw shaft 18 with a planetary gear mechanism 36 , so that the motor 32 is rotated by the rotation of the screw shaft 18 .

[0041]In this embodiment, the motor 32 is a motor with DC brushes, and consists of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com