Automatic repeating self-tapping nailing gun

A self-tapping screw, bursting technology, applied in nailing tools, manufacturing tools, etc., can solve the problems of difficult to meet the requirements of construction specifications, high construction intensity, low efficiency, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

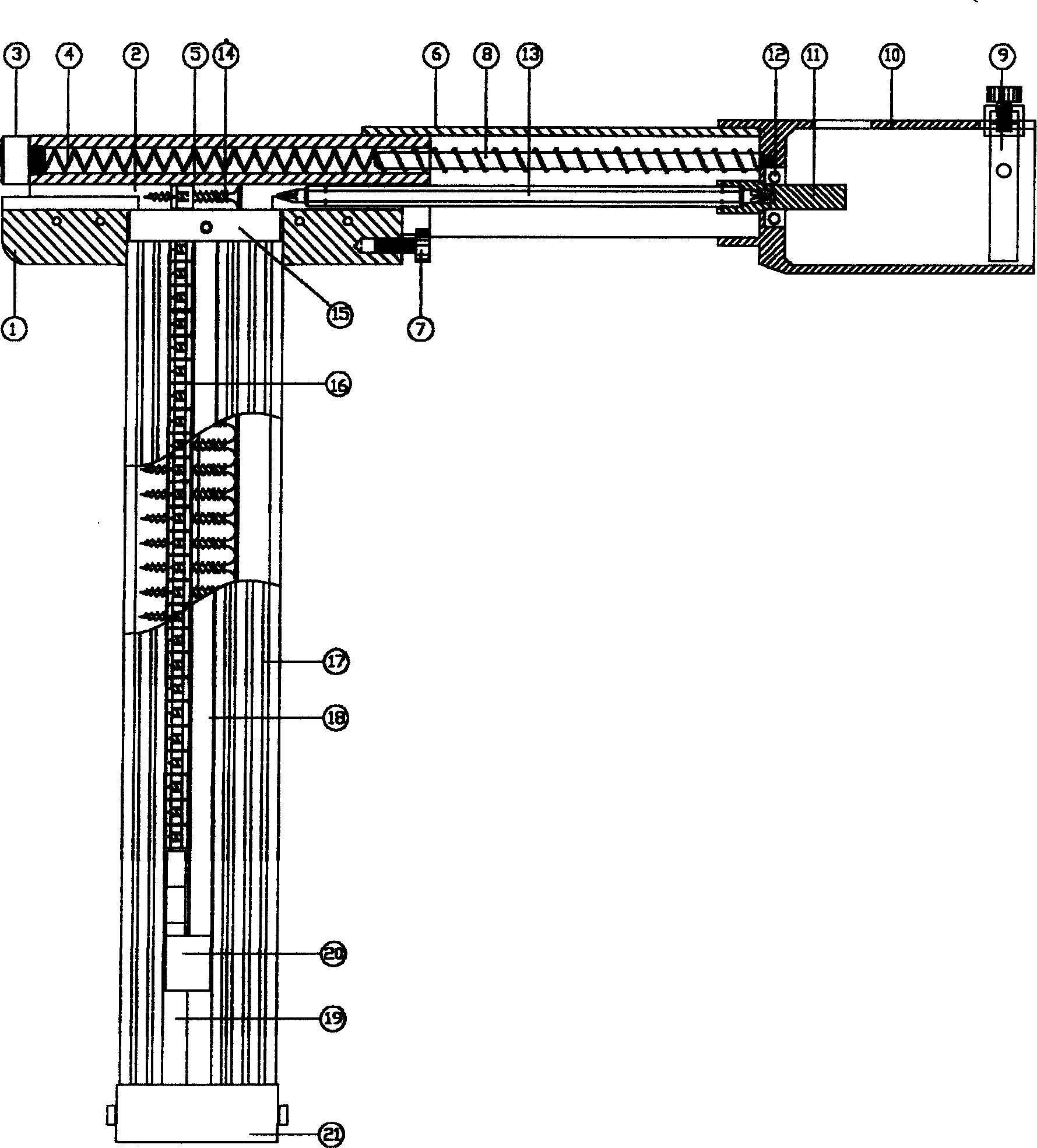

[0011] In the accompanying drawings, the main gun chamber 5 is a semi-circular casing in the shape of an 8, and the material is aluminum alloy, the front screw 3 of the upper hole of the 8 shape, the lower hole of the 8 shape is the main gun bore 2, and the main gun chamber 5 is passed by screws on both sides below. Fixing parts 1 are respectively housed. Rear chamber 6 is inverted U font and is enclosed within the rear portion of main chamber 5 and can slide on main chamber 5, forms a gun body with main chamber 5, and its material is aluminum alloy. Sheath 10 one ends are contained in the rear end of breech chamber 6 by screw, and material is cast aluminum, and spring core 8 is housed in the upper round hole of sheath 10 front ends, and spring core 8 shaft overcoats have spring 4. When the whole gun is installed, the spring 4 and the spring core 8 are packed into the main chamber 5 and the breech chamber 6 top holes. A bearing 12 is housed in the lower circular hole at the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com