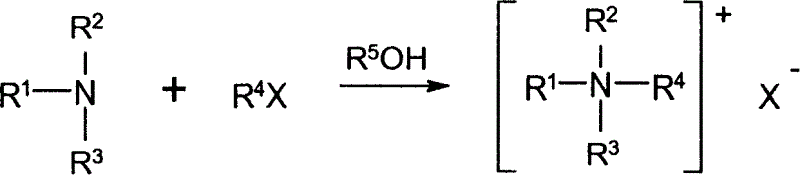

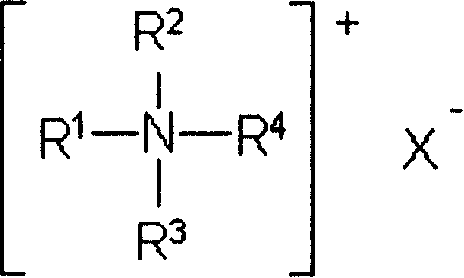

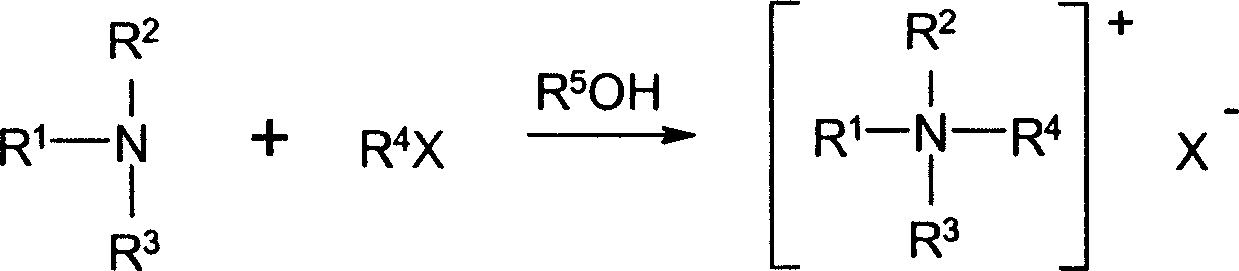

Quaternary ammonium salt and preparation thereof

A technology of quaternary ammonium salts and monohydric alcohols, which is applied in the field of quaternary ammonium salts and its preparation, using tertiary amines as raw materials to prepare quaternary ammonium salts, which can solve the problems of unsafe production, storage and transportation, human hazards, etc. The effect of convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] Example 1

[0029] Put 30g cetyl alcohol and 114g trihexadecyl tertiary amine into the reaction vessel. 8.3g of methyl chloride was introduced, the reaction temperature was 100°C, the pressure was 196KPa (gauge pressure), and the reaction was carried out for 30 hours. The reaction is stopped to obtain a product, which is a white solid with an active content of 80.36%.

Example Embodiment

[0030] Example 2

[0031] Put 30g cetyl alcohol and 130g trihexadecyl tertiary amine into the reaction vessel. Pass in 9.5g of methyl chloride, reaction temperature 85℃, pressure 147KPa (gauge pressure), after 30 hours of reaction, add 30g of cetyl alcohol, continue the reaction for 10 hours, stop the reaction to obtain the product, the product is a white solid, the content of active matter It is 71.63%.

Example Embodiment

[0032] Example 3

[0033] 16 g of stearyl alcohol and 126 g of trihexadecyl tertiary amine were put into the reaction vessel. Pass in methyl chloride, a total of 9.2g. The reaction temperature is 100°C, the pressure is 98KPa (gauge pressure), after 30 hours of reaction, the reaction is stopped, and 8 g of stearyl alcohol is added to obtain the product, which is a white solid and the active content is 85.55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com