Coating for surface of silicone rubber substrate and preparation method thereof

A coating and silicone technology, which is applied in the field of coatings and surface engineering, can solve the problems of poor coating adhesion and resistance performance defects, and achieve the effects of low volatile organic compound content, easy operation and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

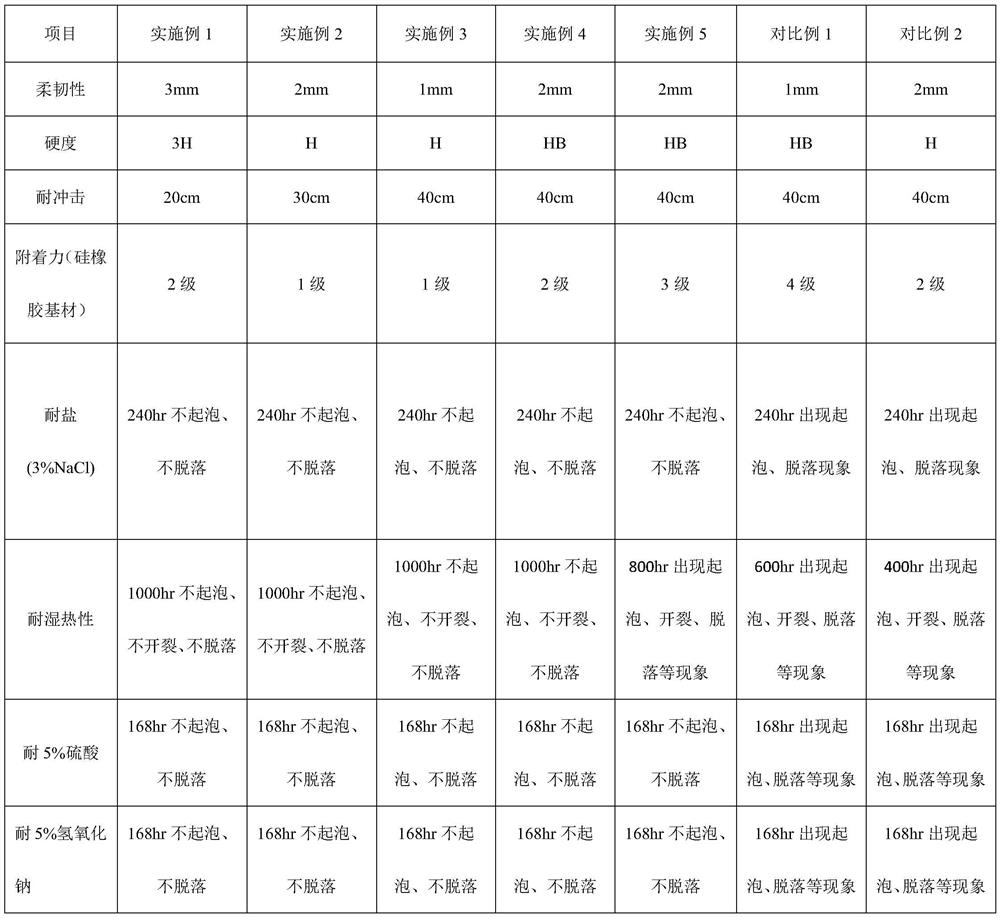

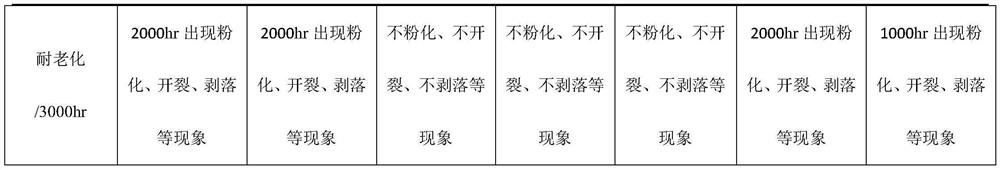

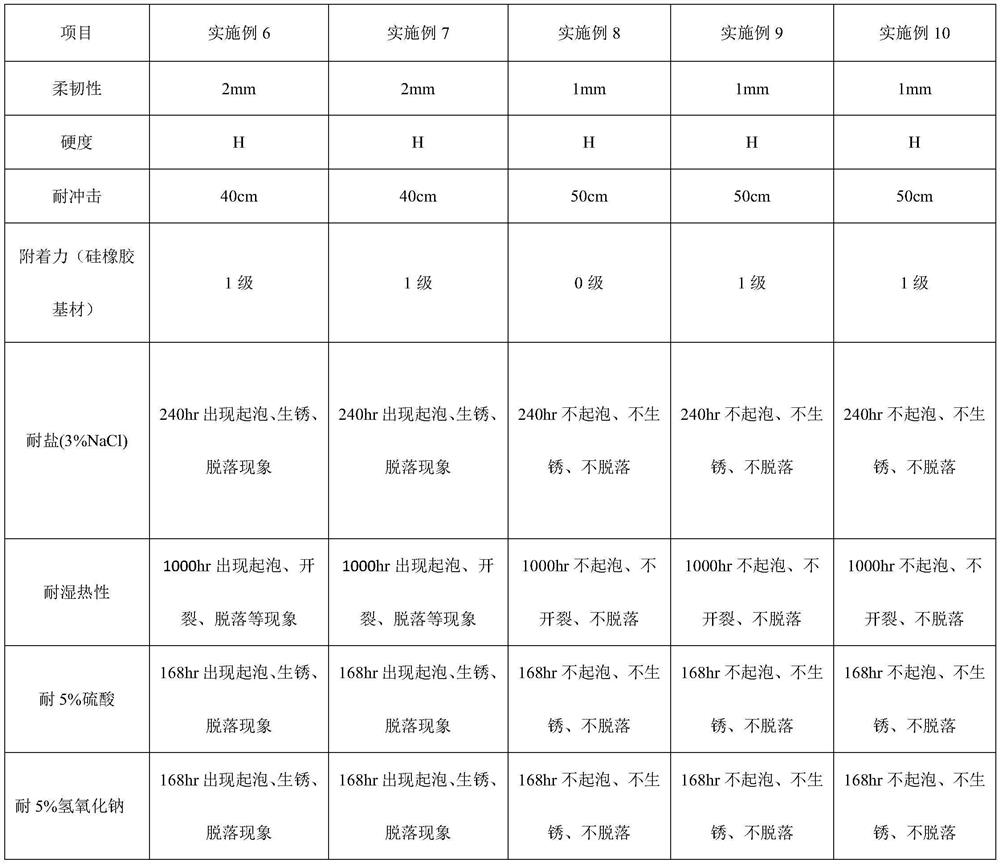

Examples

Embodiment 1

[0033] In the present embodiment, the preparation method for the coating on the surface of the silicone rubber substrate is as follows:

[0034] (1) Silicone modified polyaspartate resin

[0035] a. In parts by weight, add 90 parts of aminomethylsilane to the reagent bottle, start stirring, control the temperature at 40°C, slowly add 87 parts of diethyl maleate, and heat up to 60 ℃ heat preservation reaction for 12 hours, after passing the test, discharge to obtain resin a;

[0036] b. In parts by weight, add 115 parts of HDI trimer N3390 into the reagent bottle, start stirring, control the temperature at 40°C, slowly add 120 parts of the above-mentioned resin a, raise the temperature to 60°C for 2 hours, and obtain a prepolymer body;

[0037] c. In parts by weight, add 500 parts of polyaspartate resin NH1520 into the reagent bottle, start stirring, control the temperature at 25°C, slowly add 150 parts of prepolymer, raise the temperature to 65°C for 3 hours, A silicone-mod...

Embodiment 2

[0046] In the present embodiment, the preparation method for the coating on the surface of the silicone rubber substrate is as follows:

[0047] (1) Preparation of Silicone Modified Polyaspartic Ester Resin

[0048] a. In parts by weight, add 90 parts of aminomethylsilane to the reagent bottle, start stirring, control the temperature at 40°C, slowly add 87 parts of diethyl maleate, and heat up to 60 ℃ heat preservation reaction for 12 hours, after passing the test, discharge to obtain resin a;

[0049] b. In parts by weight, add 120 parts of HDI trimer N3390 into the reagent bottle, start stirring, control the temperature at 40°C, slowly add 110 parts of the above resin a, raise the temperature to 60°C and react for 2 hours to obtain a prepolymer body;

[0050] c. In parts by weight, add 500 parts of polyaspartate resin NH1520 into the reagent bottle, start stirring, control the temperature at 25°C, slowly add 150 parts of prepolymer, raise the temperature to 65°C for 3 hour...

Embodiment 3

[0059] In the present embodiment, the preparation method for the coating on the surface of the silicone rubber substrate is as follows:

[0060] (1) Silicone modified polyaspartate resin

[0061] a. In parts by weight, add 90 parts of aminomethylsilane to the reagent bottle, start stirring, control the temperature at 40°C, slowly add 87 parts of diethyl maleate, and heat up to 60 ℃ heat preservation reaction for 12 hours, after passing the test, discharge to obtain resin a;

[0062] b. In parts by weight, add 125 parts of HDI trimer N3390 into the reagent bottle, start stirring, control the temperature at 40°C, slowly add 100 parts of the above resin a, raise the temperature to 60°C and react for 2 hours to obtain a prepolymer body;

[0063] c. In parts by weight, add 500 parts of polyaspartate resin NH1520 into the reagent bottle, start stirring, control the temperature at 25°C, slowly add 150 parts of prepolymer, raise the temperature to 65°C for 3 hours, A silicone-modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com