Method for producing hyamine

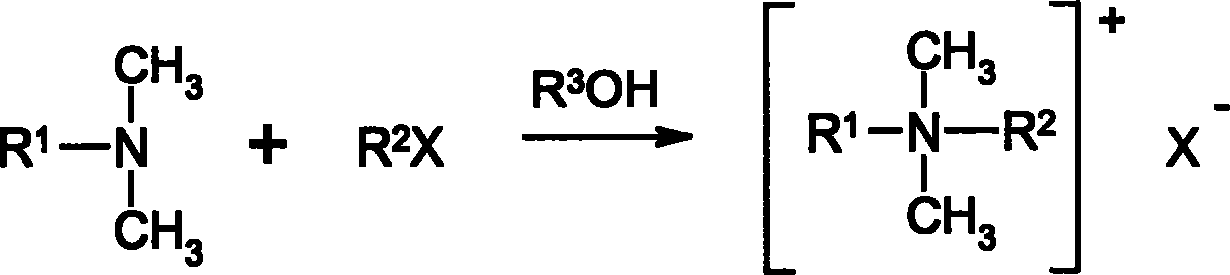

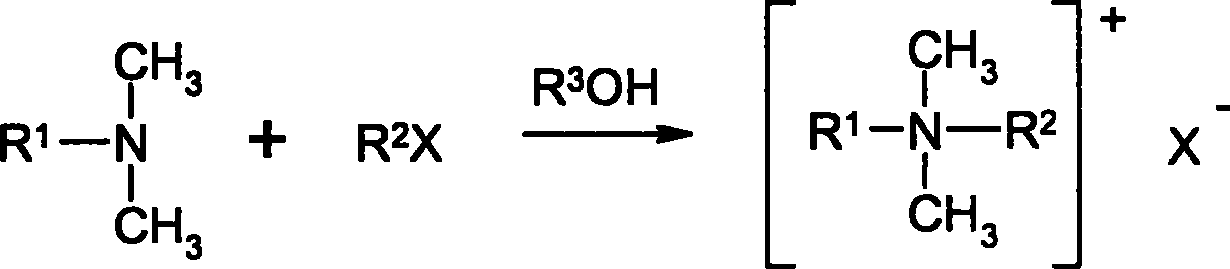

A technology of quaternary ammonium salt and monohydric alcohol is applied in the field of preparation of cationic surfactants, which can solve the problems of unsafe production, storage and transportation, human harm and the like, and achieve the effects of safe production, storage and transportation and convenient preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Put 117.5g of cetearyl alcohol and 100g of cetearyl tertiary amine into the reaction vessel. 17.5 g of methyl chloride was introduced, the reaction temperature was 100° C., the pressure was 196 KPa (gauge pressure), and the reaction was carried out for 4 hours. The reaction was stopped to obtain the product, which was a white solid, and the active matter content of the analyzed product was 51.74%.

Embodiment 2

[0031] 40g dodecyl / tetradecyl alcohol, 65g dodecyl tertiary amine are dropped into reaction vessel. Pass into 11.4g methyl chloride, 85 ℃ of reaction temperature, pressure 147KPa (gauge pressure), after reacting for 1 hour, add 35g dodecyl / tetradecyl alcohol, continue reacting after 2.5 hours, stop reaction, obtain product, product is white solid, The active matter content of the analyzed product was 48.60%.

Embodiment 3

[0033] Put 70g of hexadecyl / octadecyl tertiary amine into the reaction vessel. Pass into 8g of methyl chloride. The reaction temperature was 90°C and the pressure was 294KPa (gauge pressure). After reacting for 1 hour, 27.4g of cetyl alcohol was added, and after continuing the reaction for 5 hours, the reaction was stopped to obtain the product. %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com