Clothes dryer

A technology of a clothes dryer and a casing, applied in the field of clothes dryers, can solve the problems of reduced driving motor efficiency, noise generation, overheating of the driving motor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Reference will now be made in detail to the preferred embodiments of the invention, which are shown in the accompanying drawings.

[0026] Examples of embodiments.

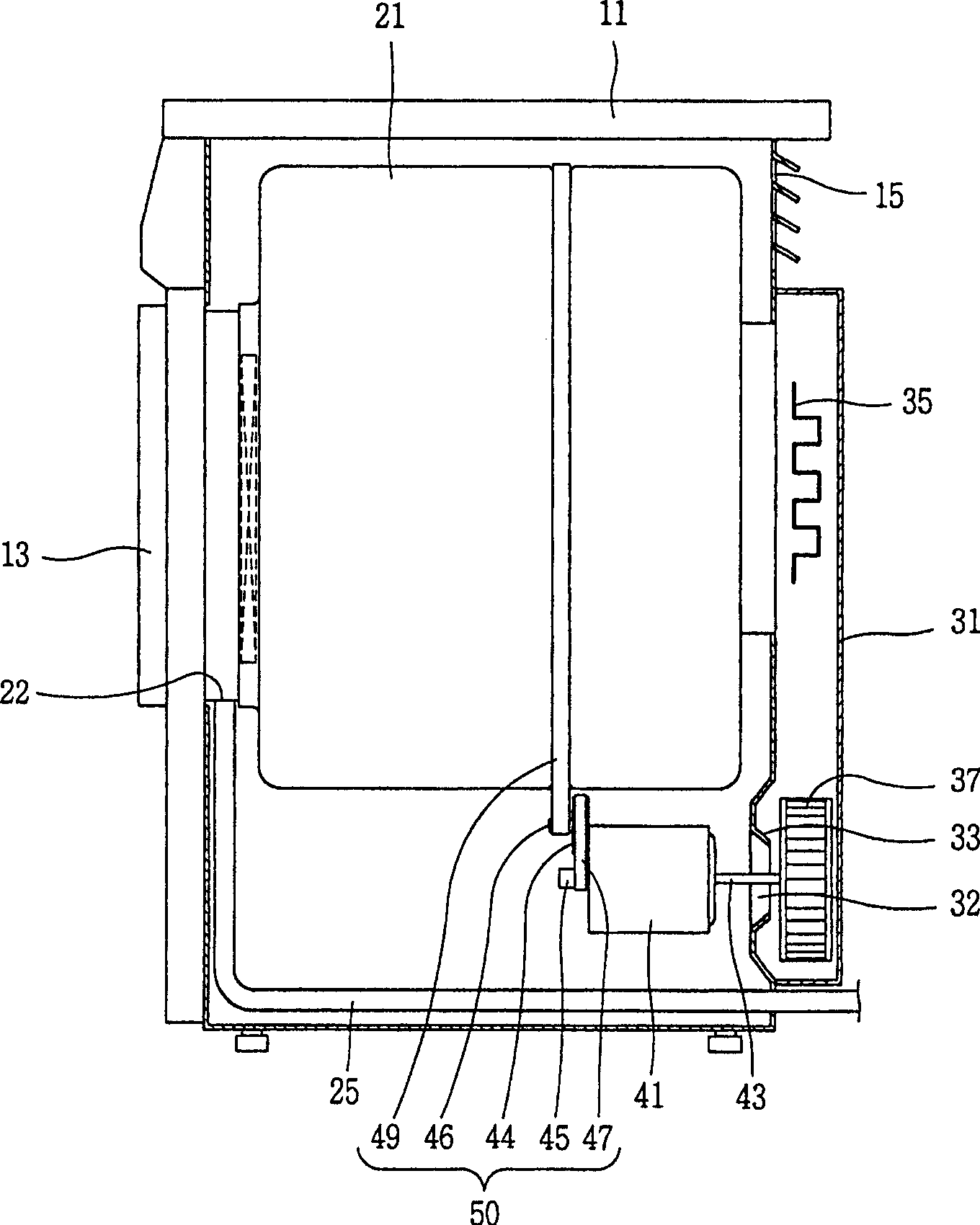

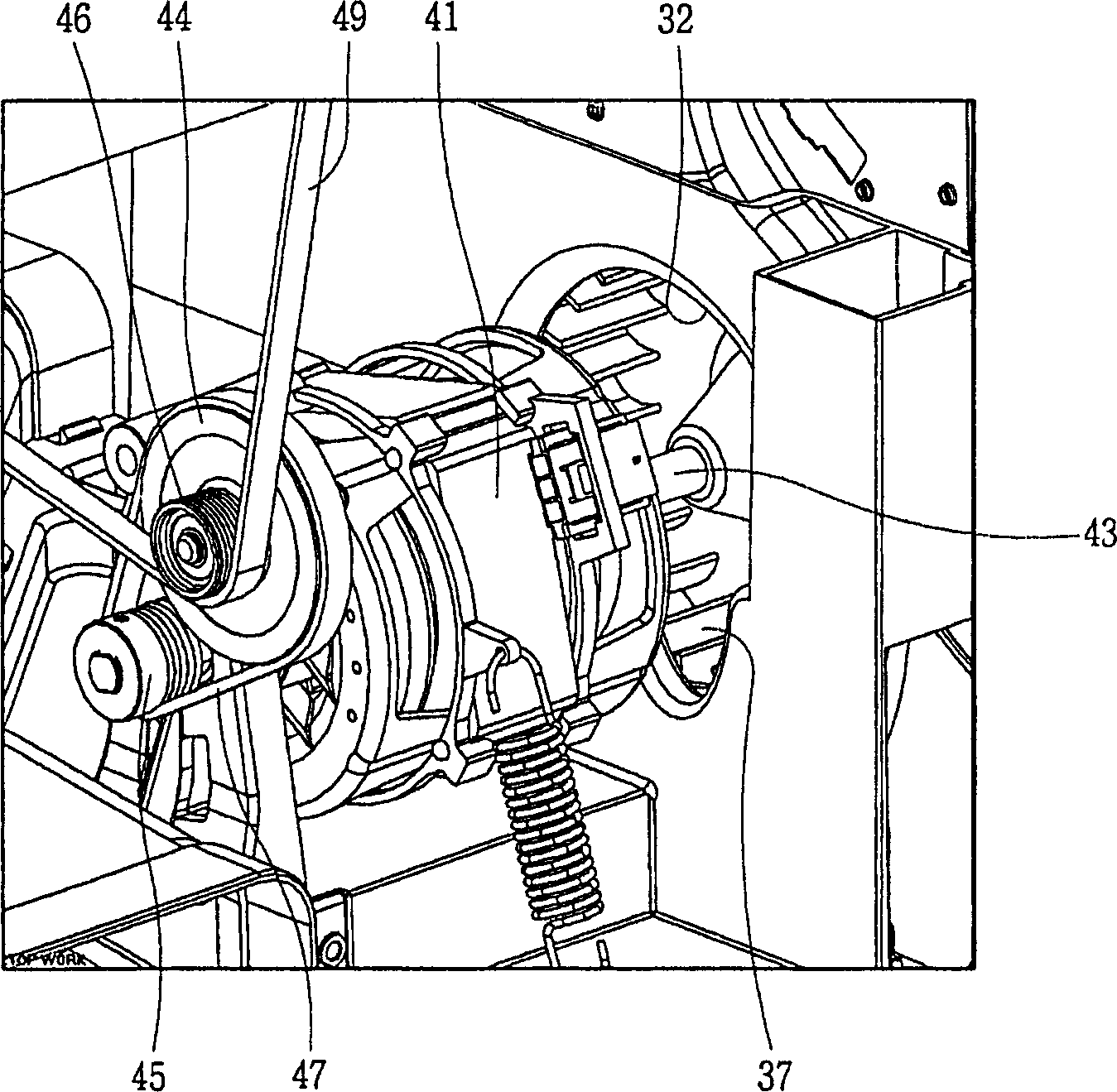

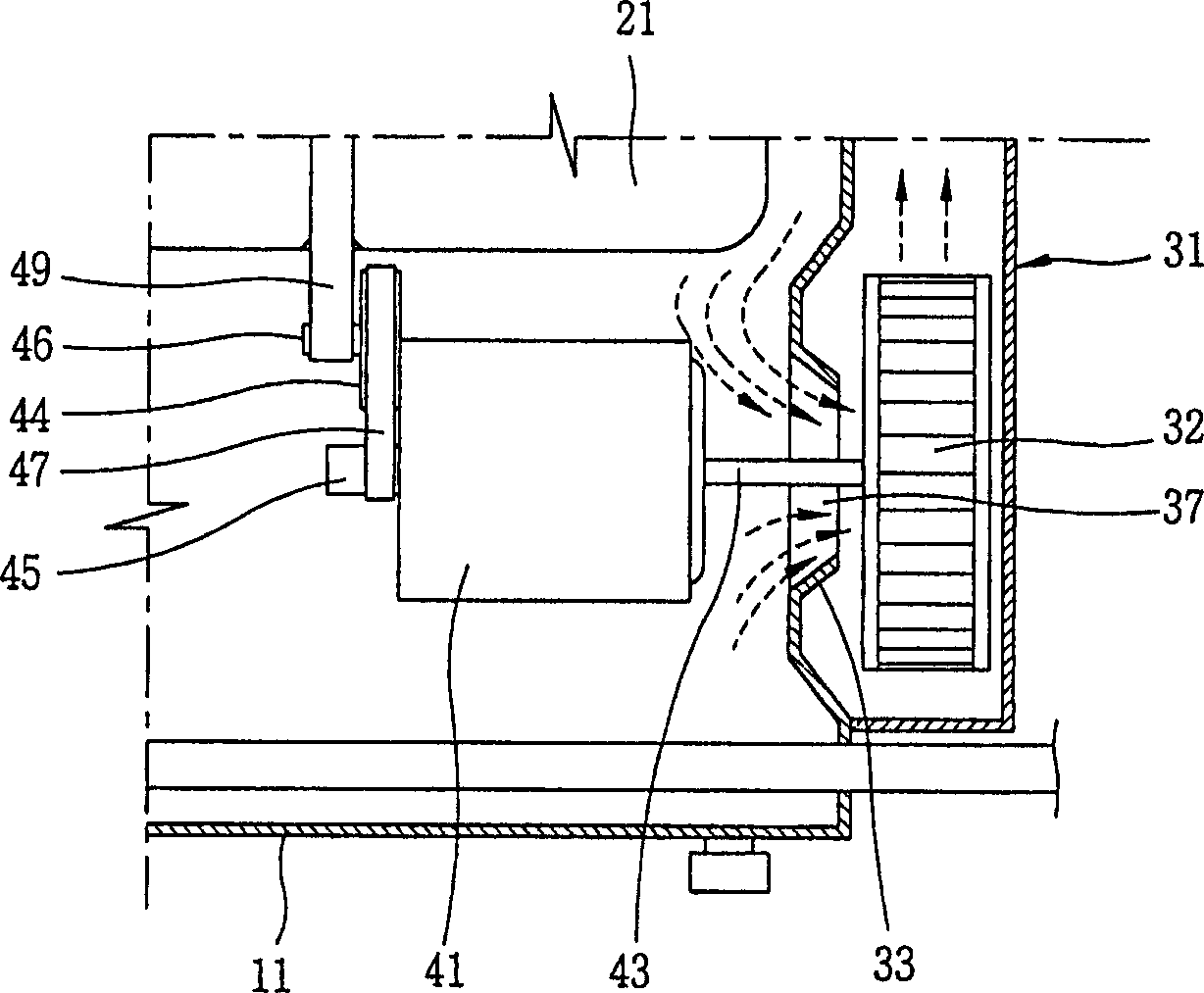

[0027] Figure 4 To illustrate a cross-sectional view according to one embodiment of the invention, Figure 5 for showing Figure 4 Perspective view of the middle suction guide, and Figure 6 for Figure 4 An enlarged view of the main components in .

[0028] As shown in the figure, a clothes dryer according to one embodiment of the present invention includes: a cabinet 80 having a receiving space therein; a drum 90 rotatably installed in the cabinet 80; a suction pipe 95 having Suction hole 95a is used to provide the air in the casing 80 into the drum 90, while the suction pipe is connected to the drum 90 at one side of the drum 90; the suction pipe arranged in the suction pipe 95 The fan 101 is used to suck the air in the housing 80 through the air suction hole 95a; to the air in the suction pipe 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com