Keypad module and method for manufacturing the same

A keypad and controller technology, applied in keypad modules and their manufacturing fields, can solve problems such as decreased production efficiency, increased cost, and changed production processes, and achieves the goal of improving production efficiency, realizing production modularization and automation, and reducing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

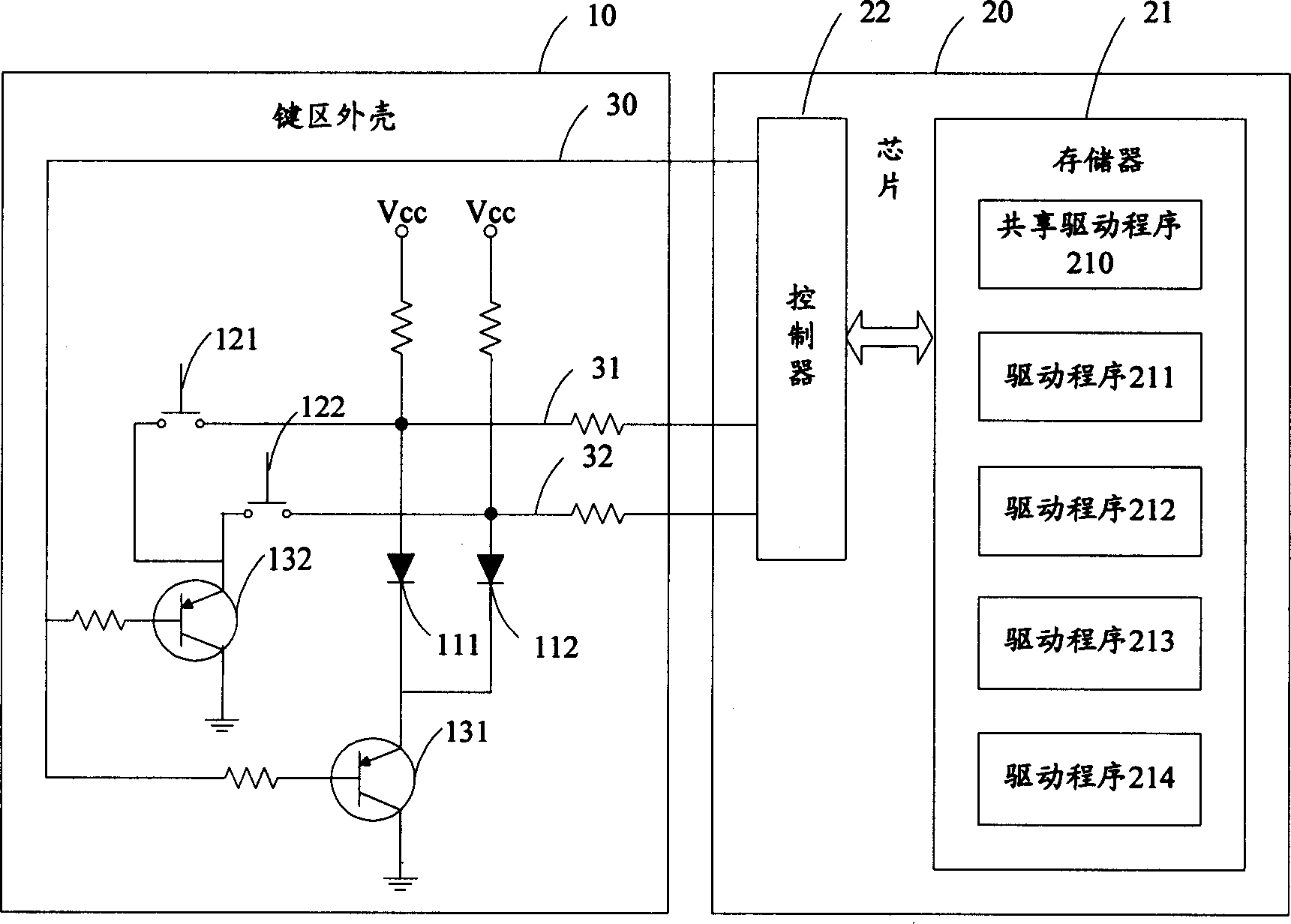

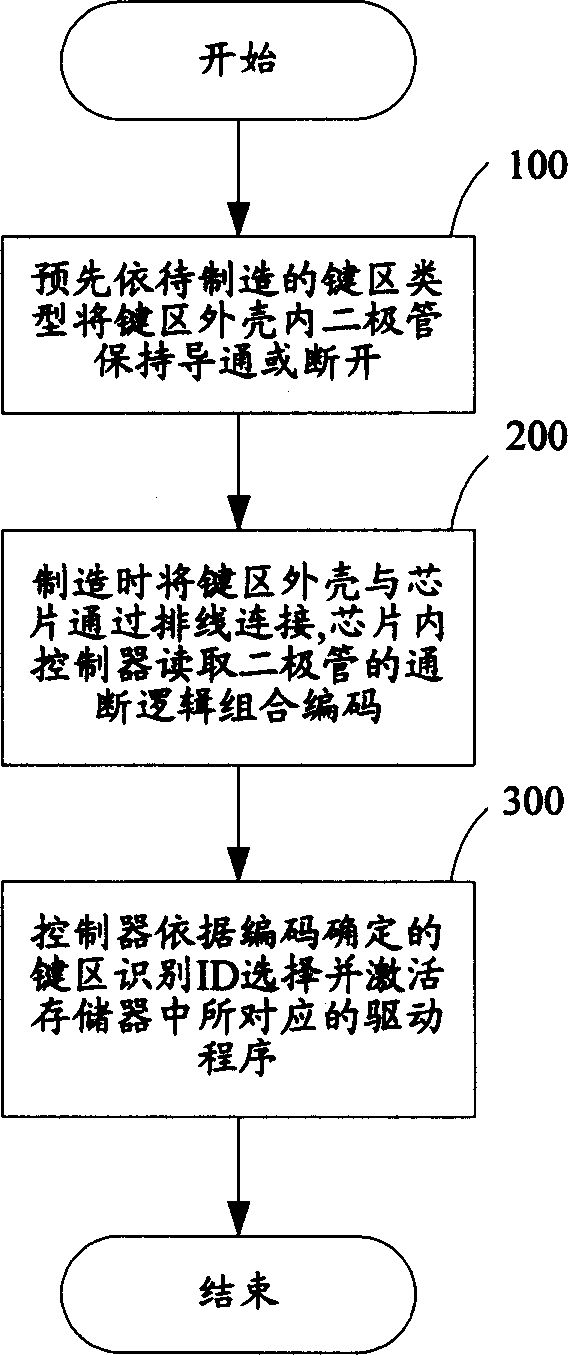

[0011] see figure 1 , is a structural schematic diagram of the keypad module of the present invention. The module includes: a keypad shell 10, which uniquely corresponds to a keypad identification ID used to identify the keypad type; a chip 20, which is shared by different types of keypads, and which is connected to the keypad shell 10 through an array. Lines 30, 31, 32 are connected. Wherein, the keypad housing 10 further includes two diodes 111, 112, the cathode of the diode 111 is connected with the cable 31, the cathode of the diode 112 is connected with the cable 32, the anode of the diodes 111, 112 is connected with the emitter of the triode 131, and the triode The base of 131 is connected to the chip 20 through the cable 30, and the collector is grounded. The chip 20 further includes a memory 21, which stores a number of keypad module shared drivers 210 and dedicated drivers 211, 212, 213, 214, wherein each dedicated driver corresponds to a different keypad identifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com