Dust-catcher with water-filtering and vortex separation device

A cyclone separator, cyclone separation technology, applied in the direction of suction filter, etc., can solve the problems of overflow, water and dust can not be fully mixed, pollute the environment, etc., to achieve the effect of increased volume, good dust collection effect, and no pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

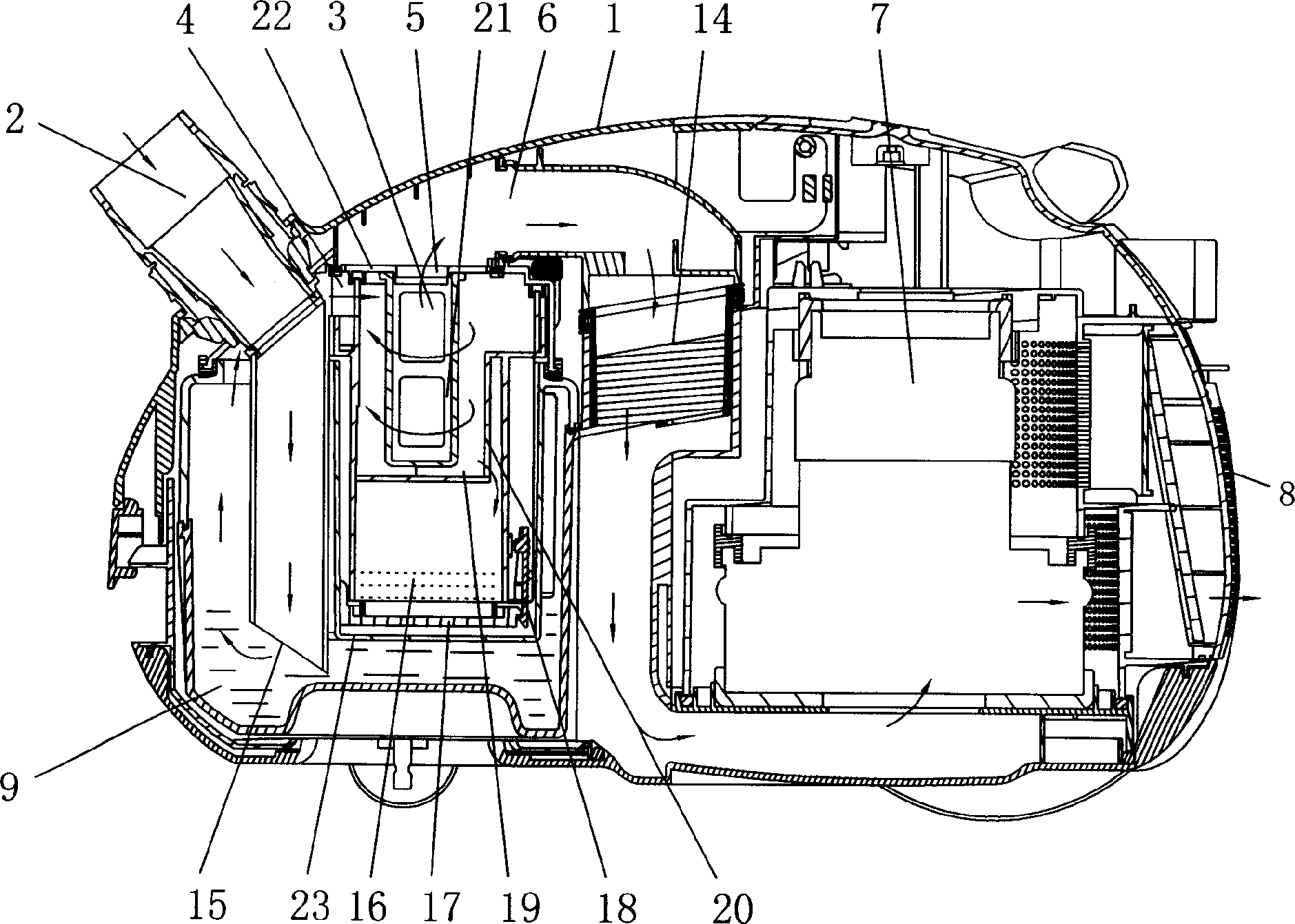

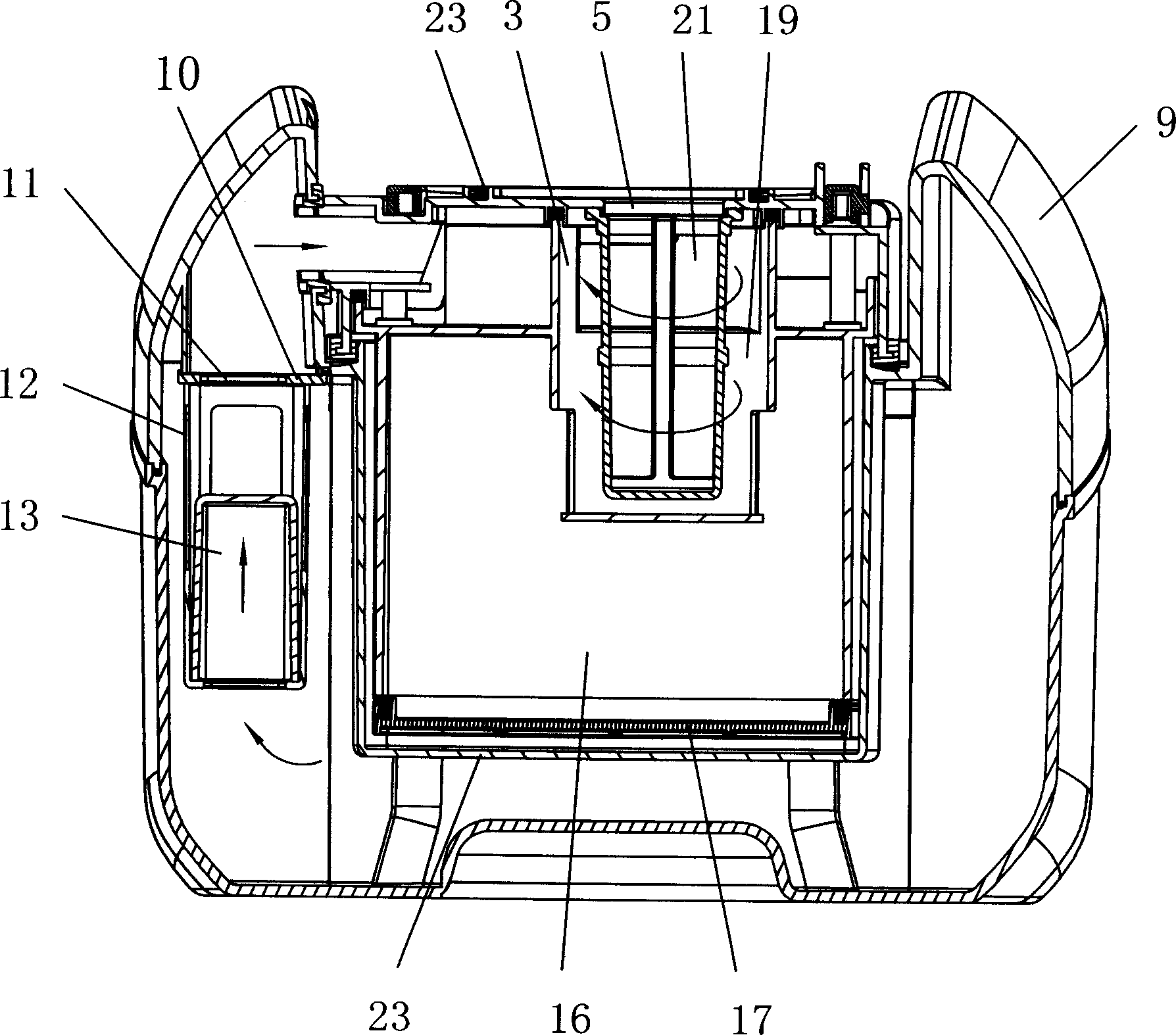

[0018] Example: such as figure 1 , figure 2 As shown, a vacuum cleaner with water filtration and cyclone separation includes a body 1, a main suction pipe 2, a cyclone separator 3, an air duct 6 inside the machine, a filter hypa 14 installed on the air duct 6 inside the machine, a vacuum motor 7, and an air outlet grille 8.

[0019] The body 1 is provided with a water cup 9, the main suction pipe 2 extends into the water surface in the water cup 9, and the outlet end face of the main suction pipe 2 extending into the water surface is an inclined plane 15, and a small part of the inclined plane 15 is above the water surface, and most of them are on Under the water surface, a concave seat 23 is provided in the water cup 9, and the cyclone separator 3 is installed in the concave seat 23. The air outlet 5 at the upper end of the cyclone separator 3 communicates with the air duct 6 in the machine through the water cup cover 22, and the cyclone separator The tangential air inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com