Closed hollow tube member

A hollow tube and component technology, which is applied to building components, on-site preparation of building components, building construction, etc., can solve the problems of unreliable lap joints, low production efficiency, and poor joint quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the drawings and embodiments.

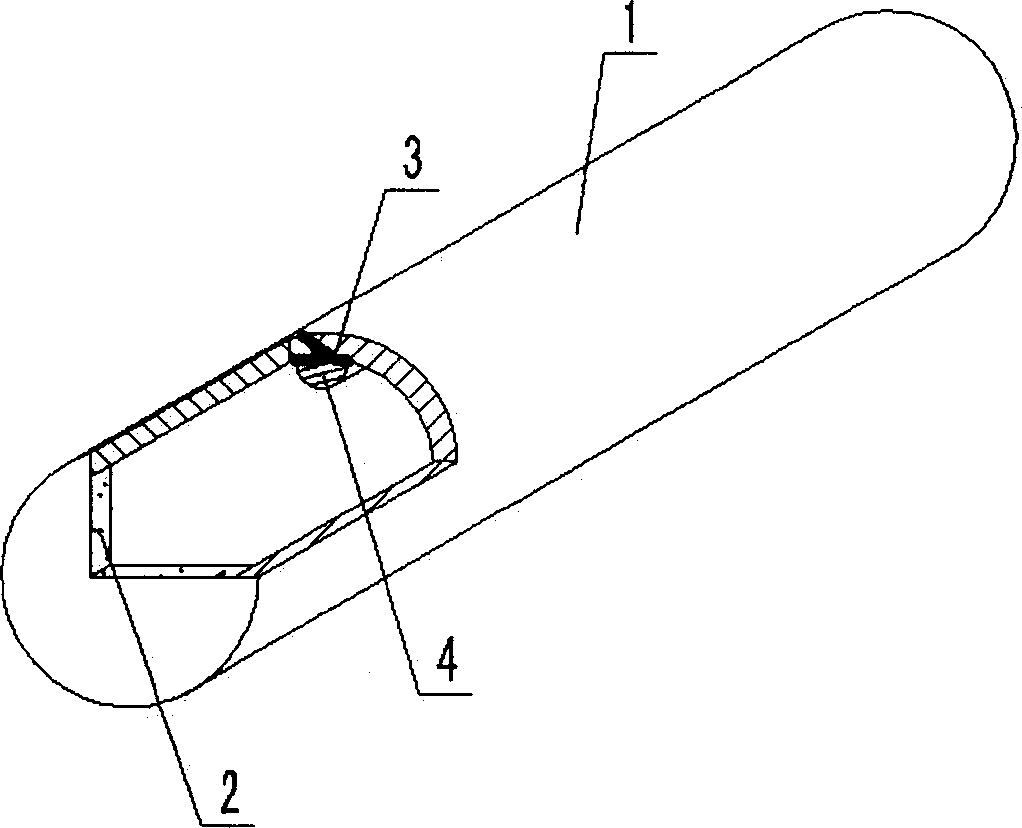

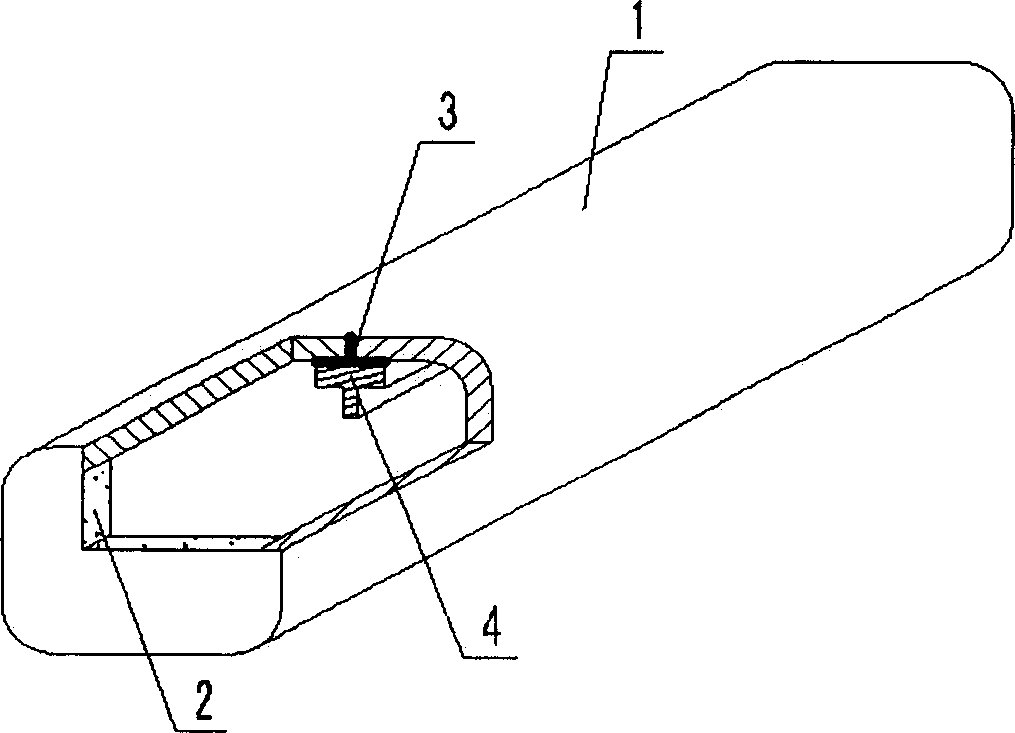

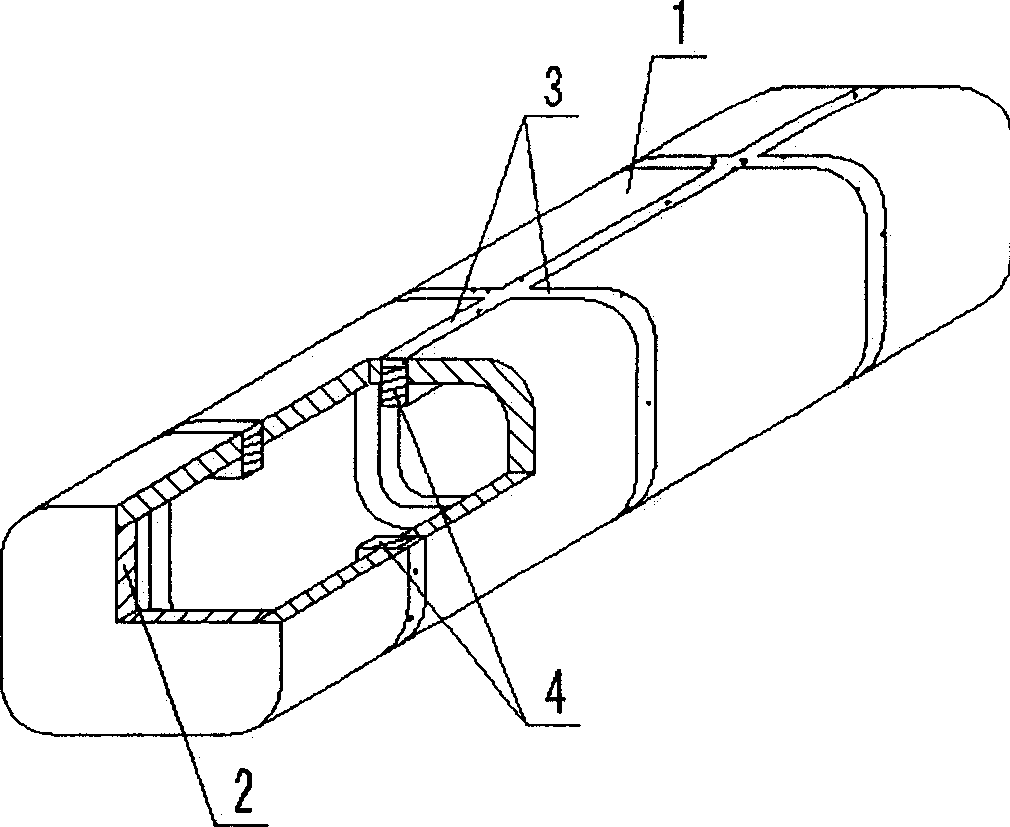

[0052] As shown in the drawings, the present invention includes a pipe body 1, a pipe end seal 2, and the pipe end seal 2 seals the pipe body 1 to form a closed hollow pipe, and is characterized in that there is at least one piece of slurry on the pipe wall of the pipe body 1 The bonding seam 3 for cementing the embryo body is provided with a prefabricated cradle member 4 that is superimposed and cemented as a whole with the embryo body at the embryo body bonding position of at least one bonding seam 3. figure 1 It is a schematic diagram of the structure of Embodiment 1 of the present invention. In the drawings, 1 is the tube body, 2 is the tube end seal, 3 is the joint seam, and 4 is the cradle member. In the following drawings, the same number is used and the description is the same. Such as figure 1 As shown, the tube end seal 2 seals the tube body 1 to form a clos...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap