Biodegradable substrate, prosthetic material for tissue regeneration and cultured tissue

A technology of biodegradable and base materials, applied in the field of biodegradable base materials, can solve problems such as difficult manufacturing, low strength, and difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

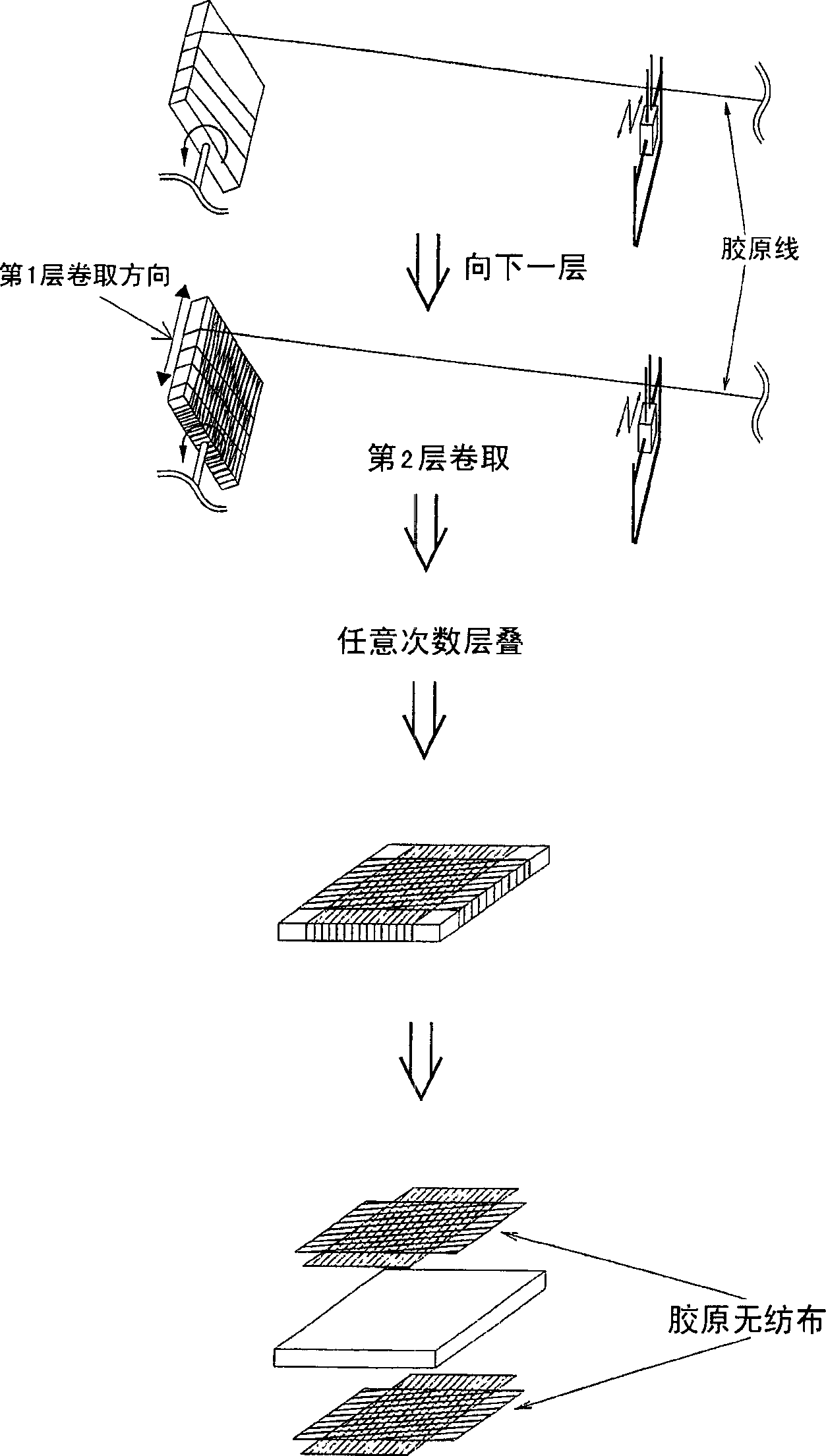

[0078] [Example 1 Production of Collagen Nonwoven Fabric]

[0079] Pig-derived type I and type III collagen powder (Nippon Ham Co., Ltd., SOFD type, lot number 0102226) was dissolved in distilled water for injection (Otsuka Pharmaceutical Co., Ltd.) to adjust to 7% by weight. Then, this 7% by weight collagen solution was filled into a syringe (manufactured by EFD, disposable tube / piston (Disposable Barrels / Pistons), 55 ml), and the collagen solution was injected into ethanol by air pressure through the needle installed on the syringe. in the slot. At this time, needles of Ultra Dispensing Tips (27G, ID: Φ0.21 mm) manufactured by EFD Corporation were attached to the syringe. After the injected 7% by weight aqueous collagen solution became a dehydrated thread, it was taken out from the ethanol tank. The pulled collagen strands were immersed in a second ethanol tank completely separated from the above-mentioned ethanol tank at room temperature for about 30 seconds to further co...

Embodiment 2

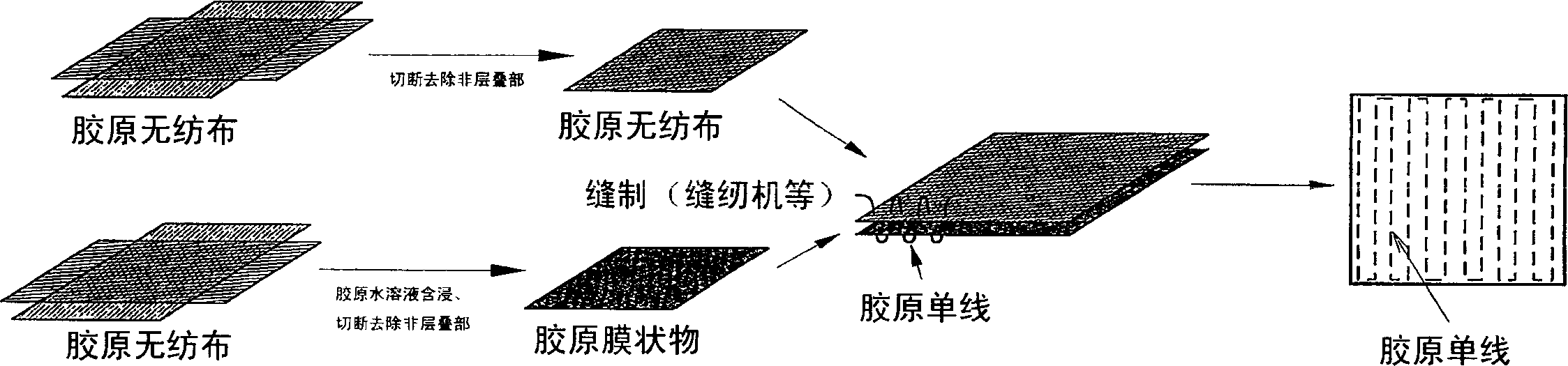

[0080] [Example 2 is processed into a collagen membrane for 2 times]

[0081] Porcine-derived type I and type III mixed collagen powder (Nippon Ham Co., Ltd., SOFD type, lot number 010226) was dissolved in distilled water for injection (Otsuka Pharmaceutical Co., Ltd.) to adjust to 1% by weight. Then, the aqueous collagen solution adjusted to 1% by weight was impregnated into one thermally dehydrated and crosslinked collagen nonwoven fabric obtained in Example 1, formed into a film, and then fully dried naturally at room temperature. Then, thermal dehydration crosslinking reaction was carried out for 12 hours under the conditions of 135° C. and reduced pressure (below 1 torr) in the same vacuum oven as above to obtain a film-like collagen nonwoven fabric.

Embodiment 3

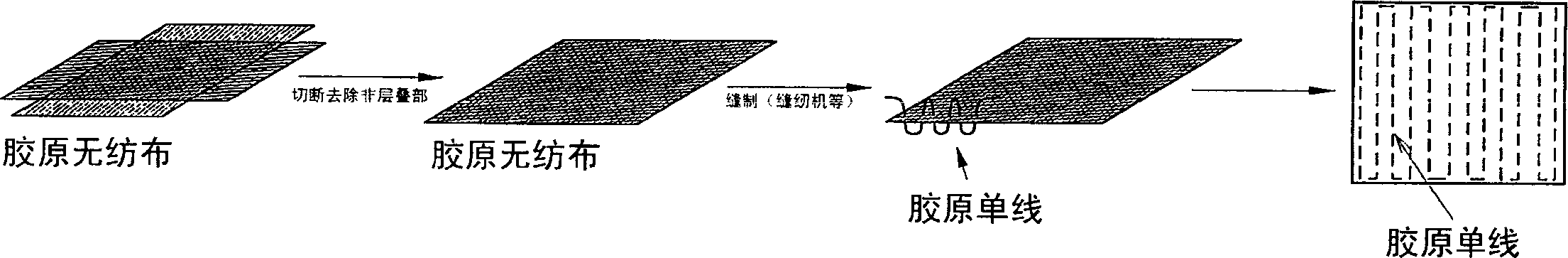

[0082] [Example 3 Production of Collagen Single Thread]

[0083] A 7% by weight aqueous collagen solution was prepared in the same manner as in Example 1. Then, after maintaining the relative humidity of the entire area of the spinning environment described later at 38% or less, the syringe (manufactured by EFD Corporation, Disposable Barrels / Pistons) filled with this 7% by weight aqueous collagen solution was 55 ml), the collagen aqueous solution was injected through the needle mounted on the syringe by applying air pressure. At this time, a needle of Ultra Dispensing Tips (27G, ID: 0.21 mm) manufactured by EFD Corporation was attached to the syringe. The injected 7% by weight collagen aqueous solution was immediately dehydrated and coagulated into a thread shape in an ethanol tank filled with 3 L of 99.5% by volume ethanol (Wako Pure Chemical Industries, Ltd., special grade). The linear collagen pulled out of the ethanol tank was immersed in a second ethanol tank complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com