High power LED package

A LED packaging, high-power technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as low thermal conductivity, insignificant heat dissipation performance, and reduced LED luminous performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

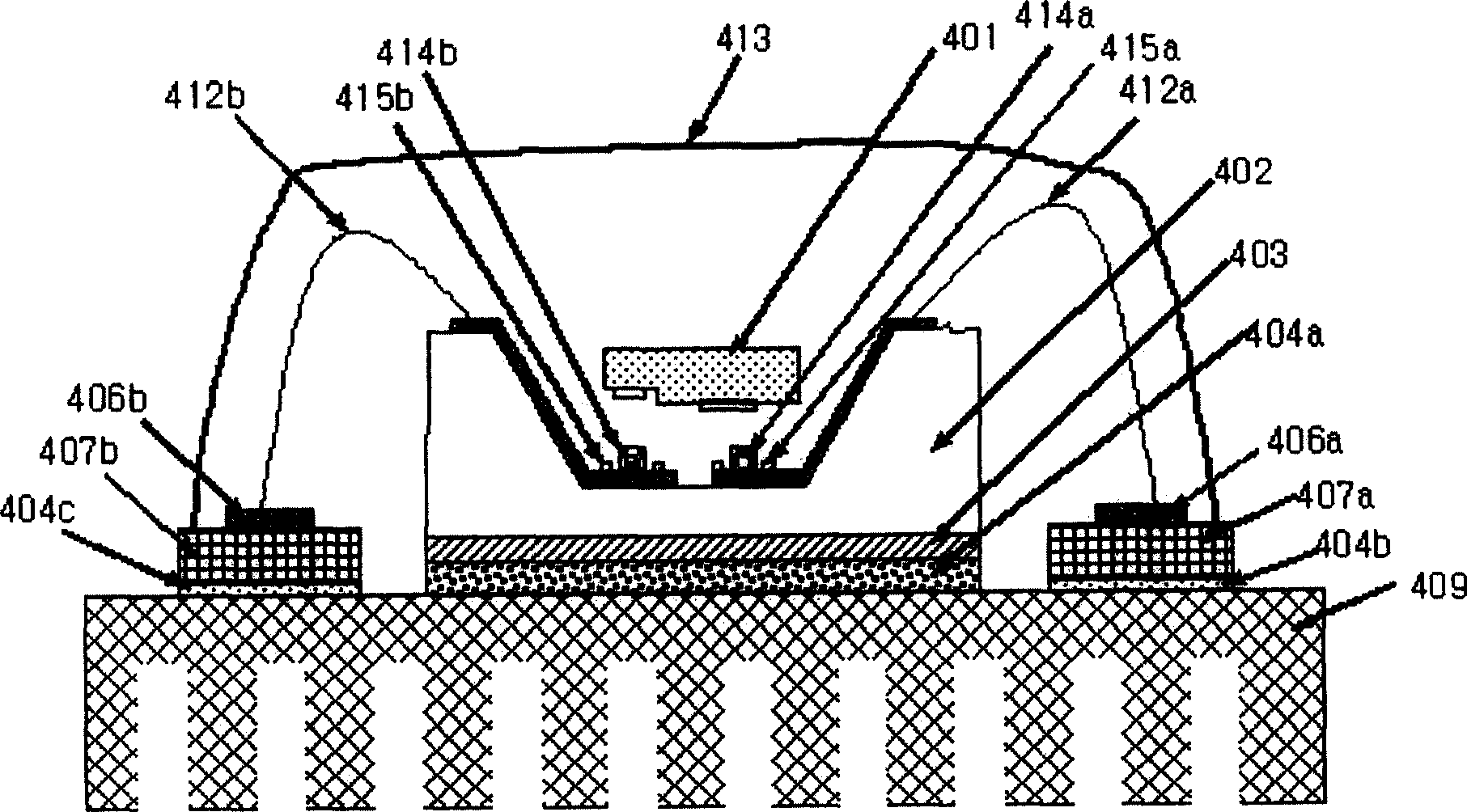

[0031] According to the first embodiment, the high-power LED package includes LED401, silicon base 402, insulating layer 403, adhesive 404a, metal lines 406a and 406b, insulating substrates 407a and 407b, heat sink 409, wires 412a and 412b, lens 413 , solder 414a and 414b, and solder dams 415a and 415b.

[0032] In this high power LED package, a silicon base 402 with a flip-chip bonded LED 401 is directly attached to the upper surface of a heat sink 409 using an adhesive 404a. Thus, the adhesive 404a includes a material having excellent thermal conductivity and a similar thermal expansion coefficient to the base 402, examples of which are aluminum paste and silver paste. Further, the heat sink 409 can be made of conductor or non-conductor.

[0033] refer to image 3 , the silicon base 402 has a groove to accommodate the LED 401 therein. The grooves of the base 402 are formed by subjecting a silicon wafer mainly used for manufacturing the base to wet etching using a potassiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com