High-strength composite zeolite deioidining adsorbent and its preparing method

A composite zeolite and adsorbent technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of low particle strength, reduced service life, easy crushing and pulverization, etc., and achieve high deiodination efficiency and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] STI mineral raw powder is subjected to cation exchange according to the following steps to make H-STI zeolite:

[0026] 1. Add the original STI powder to 1.0mol / l ammonium chloride solution, the solid-to-liquid ratio is 1:10, heat to 95-103°C and reflux for 2 hours, exchange four times, wash and dry with water.

[0027] 2. The ammonium chloride-exchanged STI powder is roasted at 500°C for 3 hours to convert it into a hydrogen-type zeolite.

[0028] 3. Add the calcined hydrogen-type zeolite to 0.5 mol / l acetic acid with a solid-to-liquid ratio of 1:10, heat to 95-100° C. for 2 hours, wash and dry to obtain H-STI powder.

Embodiment 2

[0030] H-STI powder and H-ZSM-5 powder are mixed in a ratio of 70 / 30, and then mixed with binder silica sol (SiO 2 Content 25wt%) mixes, makes the bead of diameter 2 millimeters in the rolling ball machine. The amount of zeolite in the pellets and the SiO in the binder 2 The mass ratio is 75 / 25.

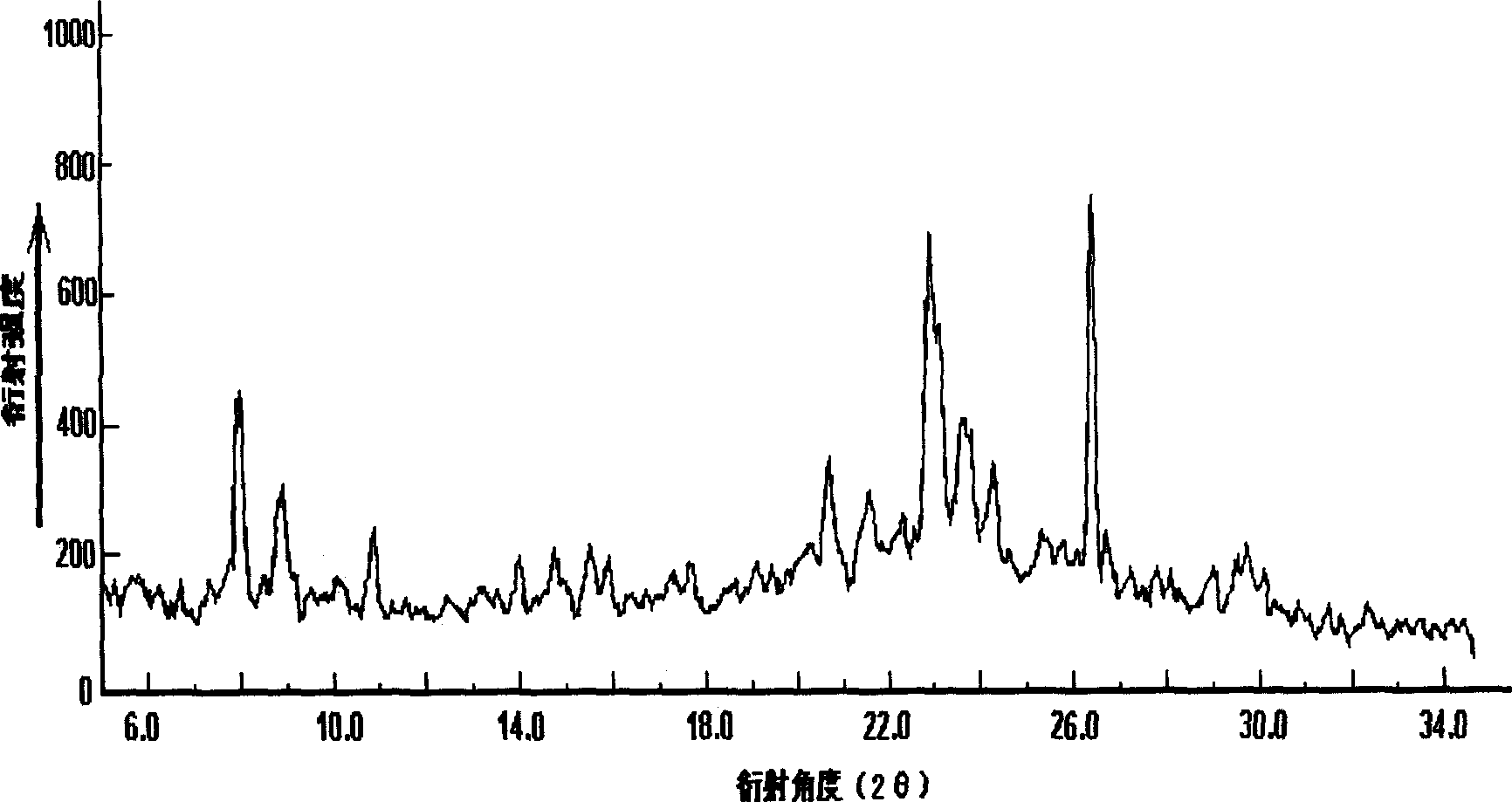

[0031] The X-ray diffraction pattern of the pellet is shown in the attached figure 1 . Its main feature is that the ratio of the total net intensity / total diffraction intensity reflecting the relative content of its crystalline substances is 0.28. The pellets had an average crush strength of 18 Newtons / pellet.

Embodiment 3

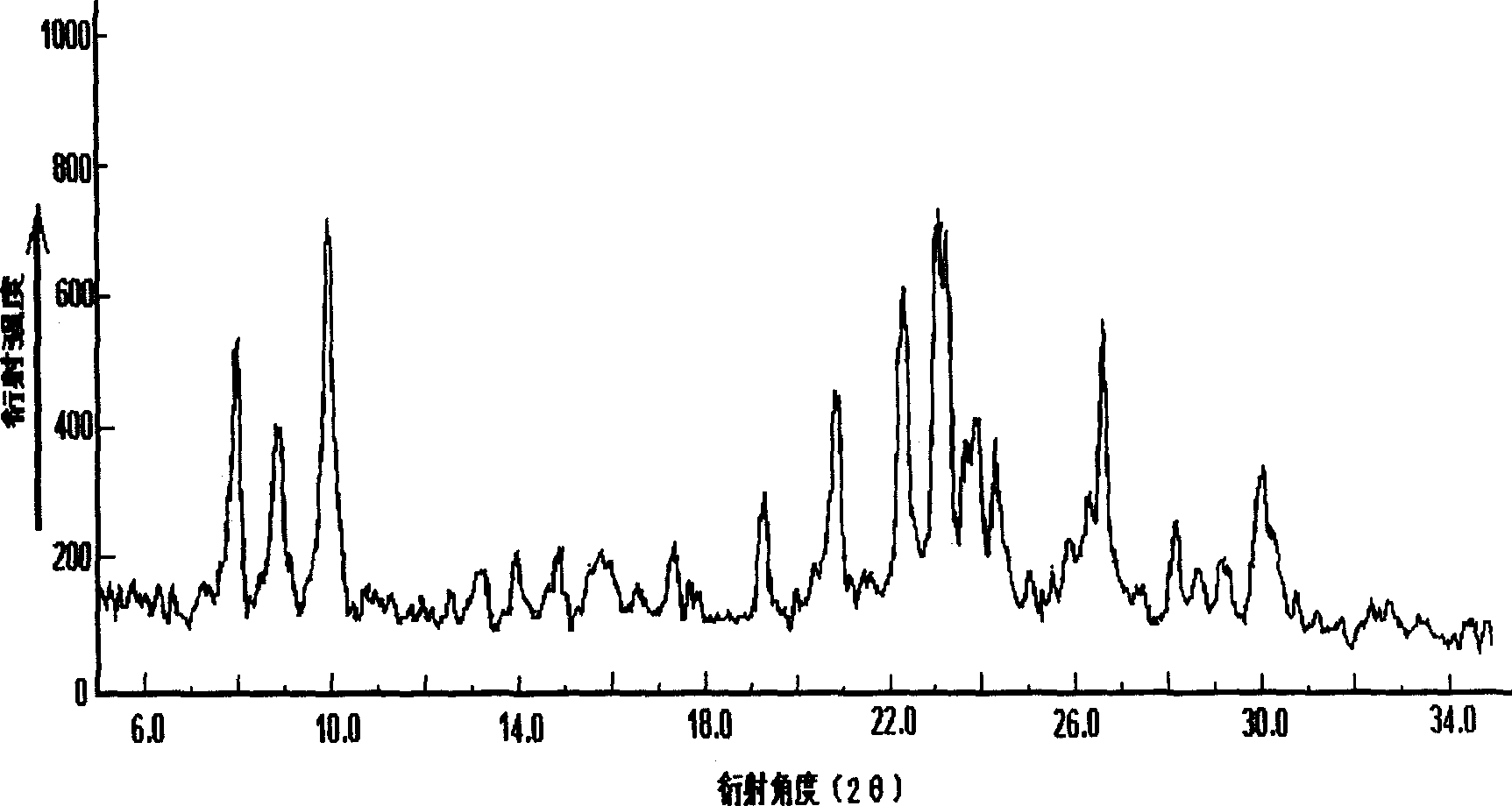

[0033] The pellets prepared in Example 2 were heated in a closed stainless steel reactor for hydrothermal strengthening treatment at a temperature of 180 degrees for 24 hours. After the treatment, the pellets of the composite substrate adsorbent were obtained, and its X-ray diffraction pattern is shown in the attached figure 2 . The ratio of total net intensity / total diffraction intensity reflecting the relative content of its crystalline substances is 0.38. Its main characteristic diffraction peak d=10.9~11.3(vs); 9.6~10.0(vs); .9.0~9.2(vs); 8.7~8.9(ms); 7.8~8.1(ms); 4.4~4.7(ms); 4.2~4.3(ms); 3.9~4.1(vs); 3.7~3.9(vs); 3.6~3.8(ms); 3.2~3.4(vs); 3.0~3.1(ms). Contrast attached figure 1 and 2 , it can be seen that the total relative content of zeolite in the pellets increased by 36% after hydrothermal strengthening treatment. The average crushing strength of the pellets after strengthening treatment increased by 2.2 times compared with that before treatment, reaching 40 New...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com