Glass fiber reinforced plastic door and door pocket integral-shaping mould and its production method

A technology of integral molding and production method, which is applied in the mold field of integral molding of glass fiber reinforced plastic doors and door pockets, can solve the problems of poor decorative effect, lack of integrity, and low production efficiency, and achieve simple and easy demoulding, good decorative effect, and easy installation fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

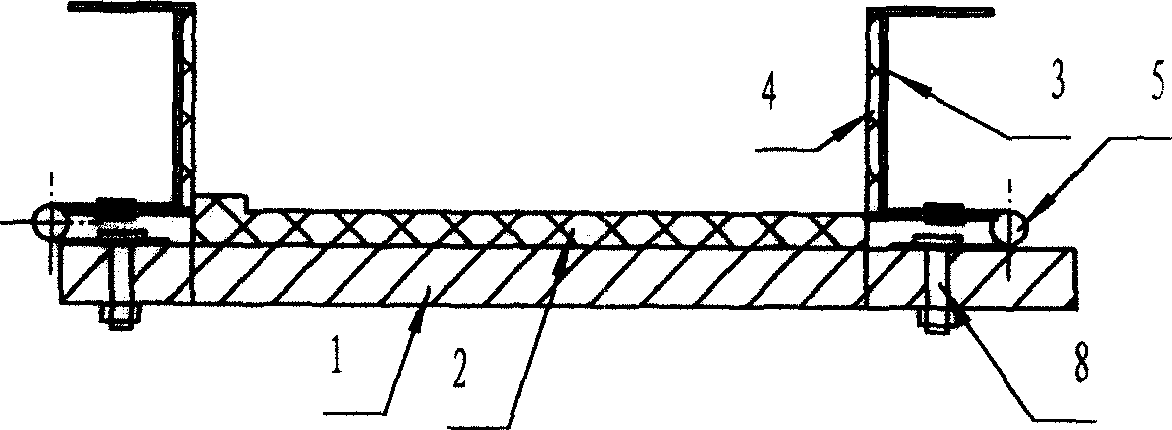

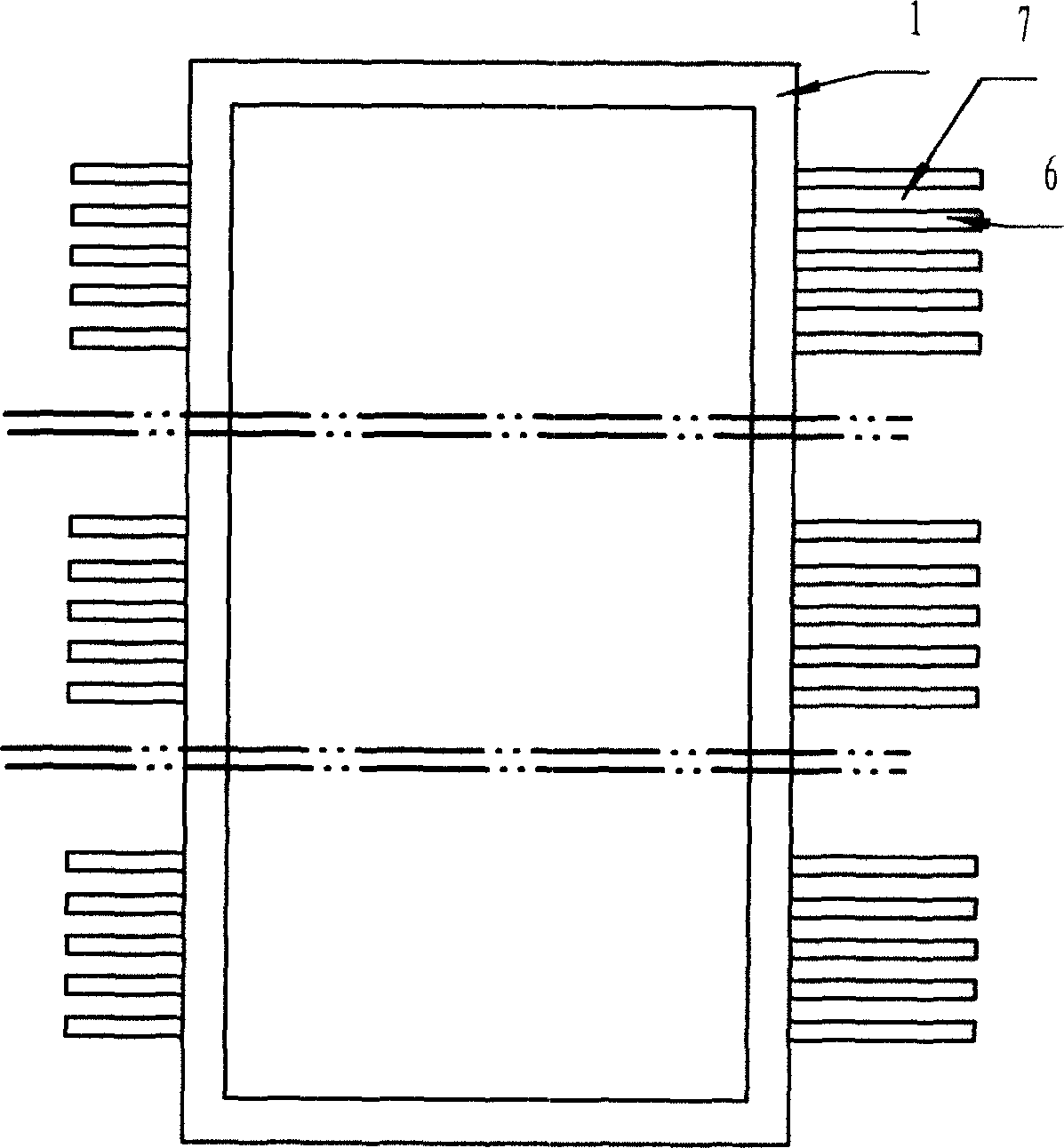

[0029] Here is a mold for the door and how to do it:

[0030] The mold for making the door is roughly the same as the mold for making the door cover. There are also bottom formwork with bottom supports on the upper formwork and side formwork with side supports, but the bottom formwork is wider, and the bottom formwork and upper formwork are used as the front of the door. and back template. There are four side formworks. The width of the side formwork is the thickness of the door. The four side formworks are distributed around the bottom formwork, one on each side. The relevant dimensions correspond to the size of the door. The method of making the door is exactly the same as the method of making the door pocket, but Do not pre-embed fasteners.

[0031] The door and the door cover made by the mold of the invention have good integrity, no deformation, no material waste, and good decorative effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com