Light emitting diode lamp with light pipes

A light guide and hollow tube technology, applied in the field of light sources, can solve problems such as increasing installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] For a better understanding of the present invention and its other and further objects, advantages and capabilities, reference is made to the following description and appended claims taken in conjunction with the accompanying drawings.

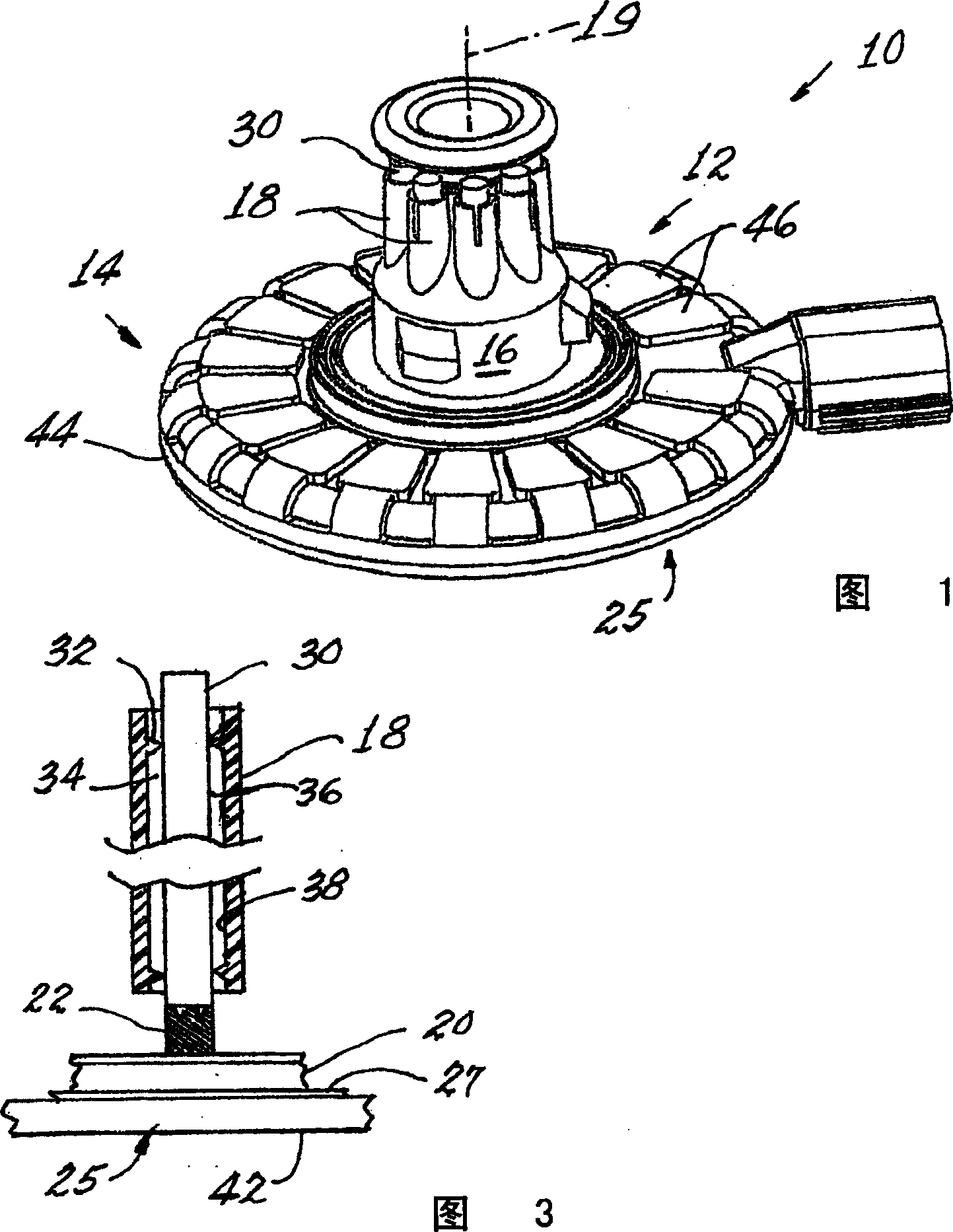

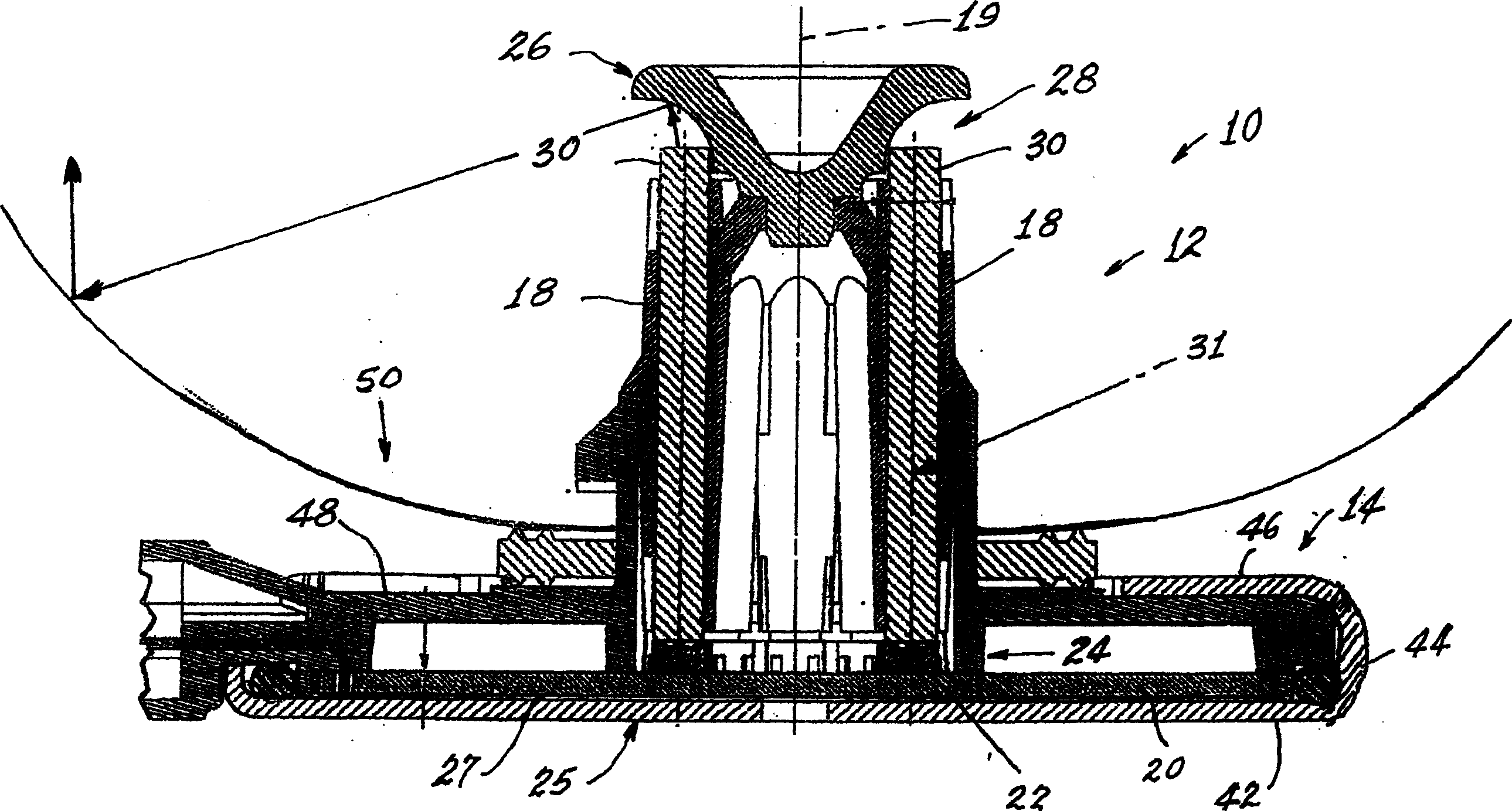

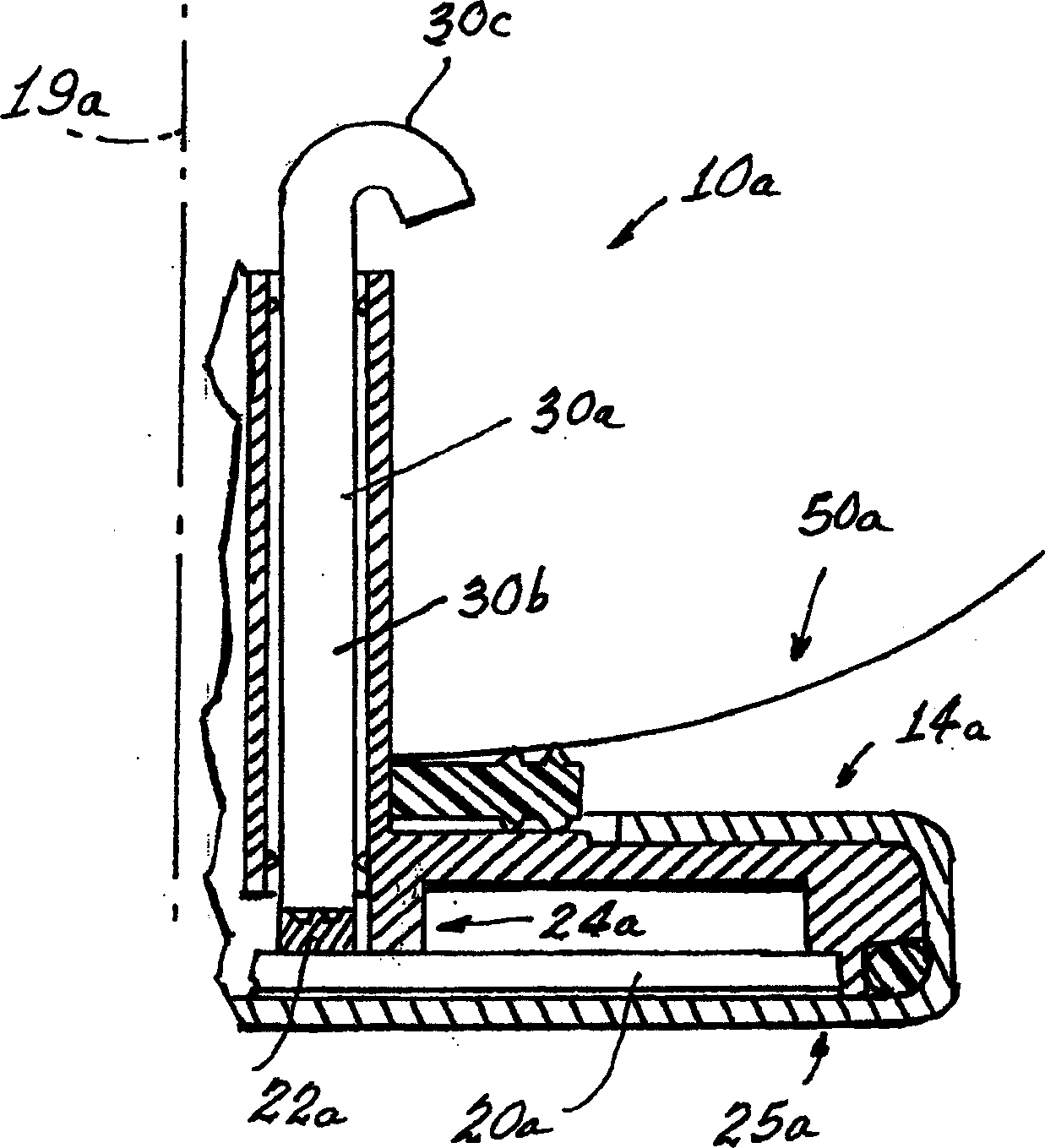

[0014] Referring now to the drawings in more detail, FIG. 1 shows an LED light source 10 including a housing 12 having a base 14 . A hollow core 16 protrudes from the base 14 and is generally cylindrical and surrounded by a plurality of elongated hollow tubes 18 . The hollow core 16 and the bottom 14 are arranged around a longitudinal axis 19 . In the preferred embodiment of the invention, there are eight tubes 18; however, the actual number of tubes may depend on the light output of the individual LEDs, and the number of tubes may be reduced as the light output increases. printed circuit board 20 (see figure 2 ) is positioned within the base 14 and has a plurality of LEDs 22 operatively secured thereto. Each of the plurality of LEDs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com