LED lamp and lamp reflector assembly

A technology of LED lamps and reflectors, which can be used in vehicle parts, transportation and packaging, lighting and heating equipment, etc., and can solve the problems of increasing installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] For a better understanding of the present invention and its other and further objects, advantages and capabilities, reference is made to the following description and appended claims taken in conjunction with the accompanying drawings.

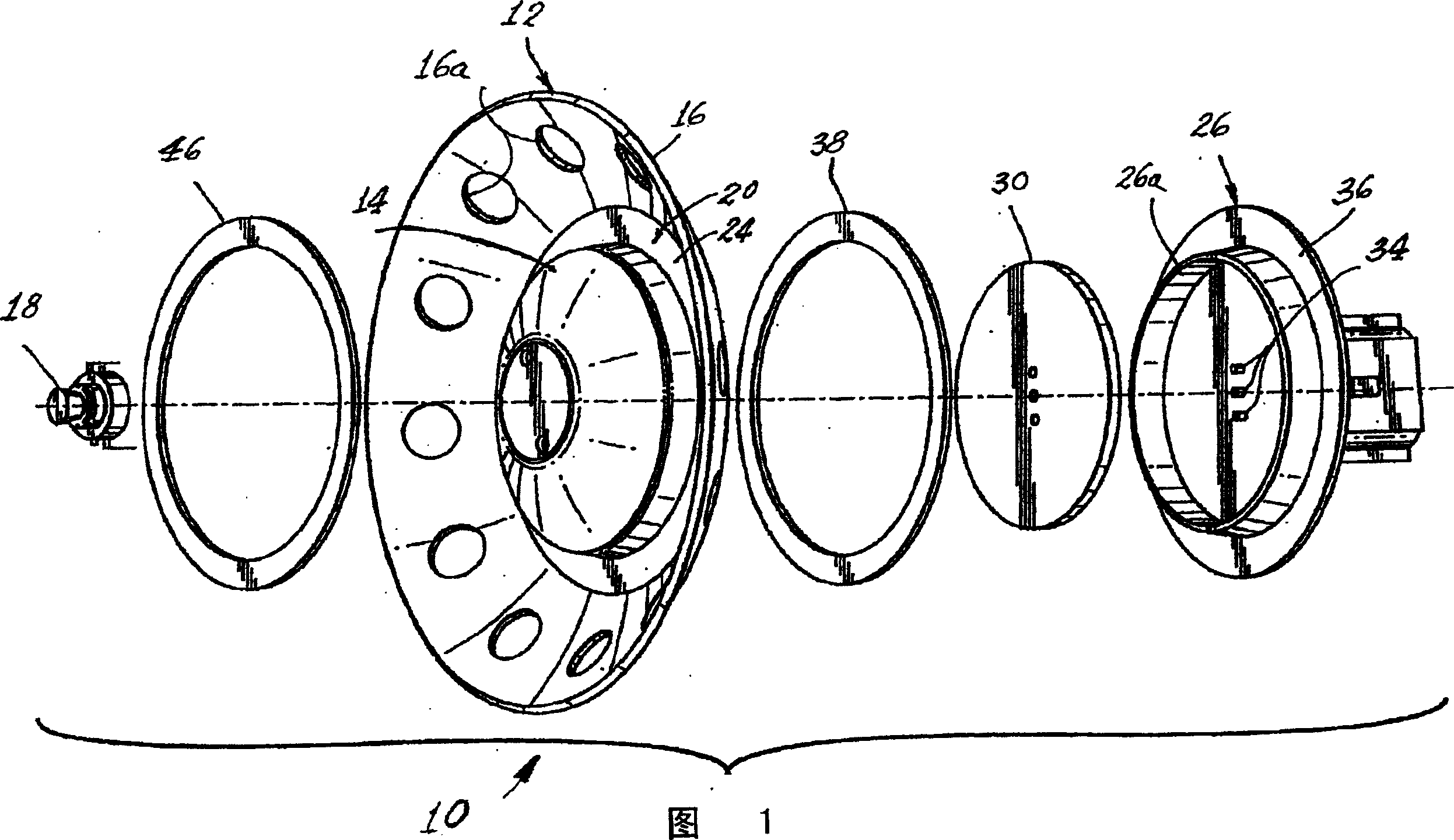

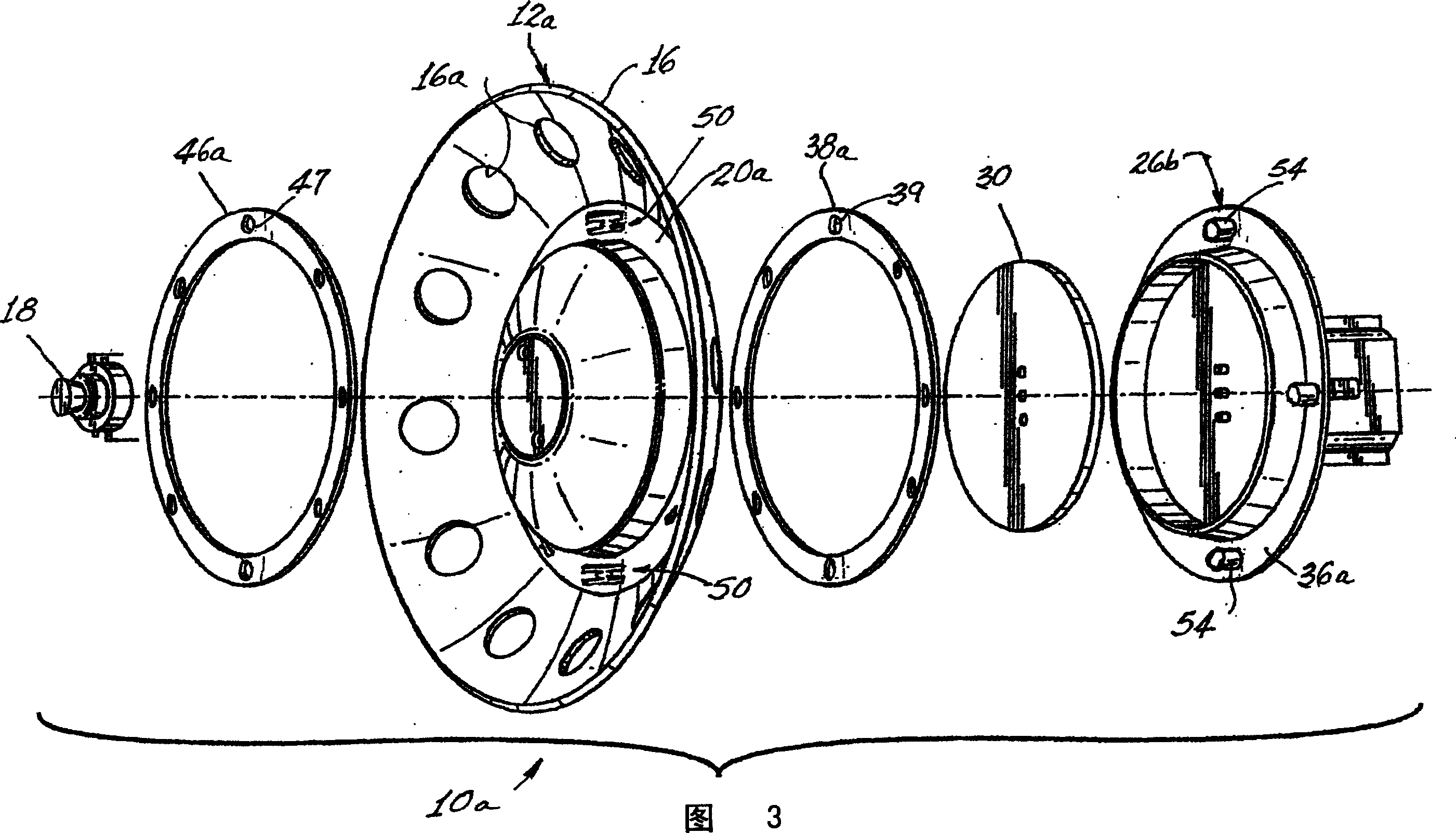

[0014] Referring now to FIG. 1 , there is shown an LED lamp 10 having a generally concave heat sink 12 with a raised frusto-conical central portion 14 surrounded by an outer edge 16 . The fins 12 are preferably formed of aluminum or other metal, and at least the frusto-conical central portion preferably has a reflective coating, for reasons that will become more apparent below. To further aid in heat dissipation, the outer edge 16 may be provided with a plurality of openings 16a.

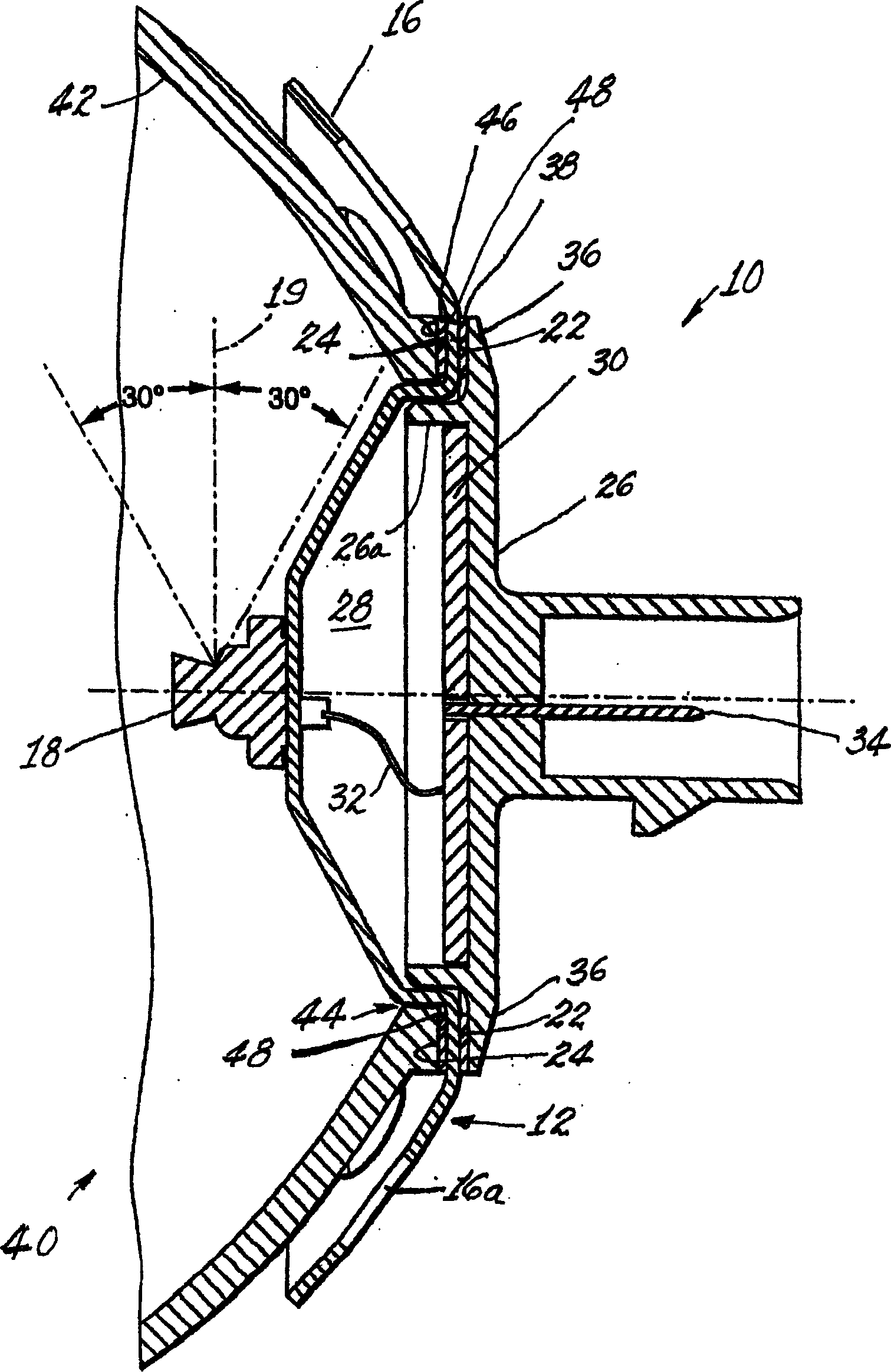

[0015] Side-emitting LEDs 18 are mounted on the frusto-conical central portion 14 . In a preferred embodiment, the side emitting LED will have a vertical axis 19 (see figure 2 ) leaves the distribution of 60°±30°. A peripheral flat region 20 is formed betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com