Method for supporting and incorporating bearing, protective cover and reprocessing method

A protective cover and reprocessing technology, applied in the direction of shafts and bearings, supporting machines, bearing components, etc., can solve problems such as difficult to obtain slip rings, difficult to achieve, etc., to achieve the effect of reducing danger and excellent sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

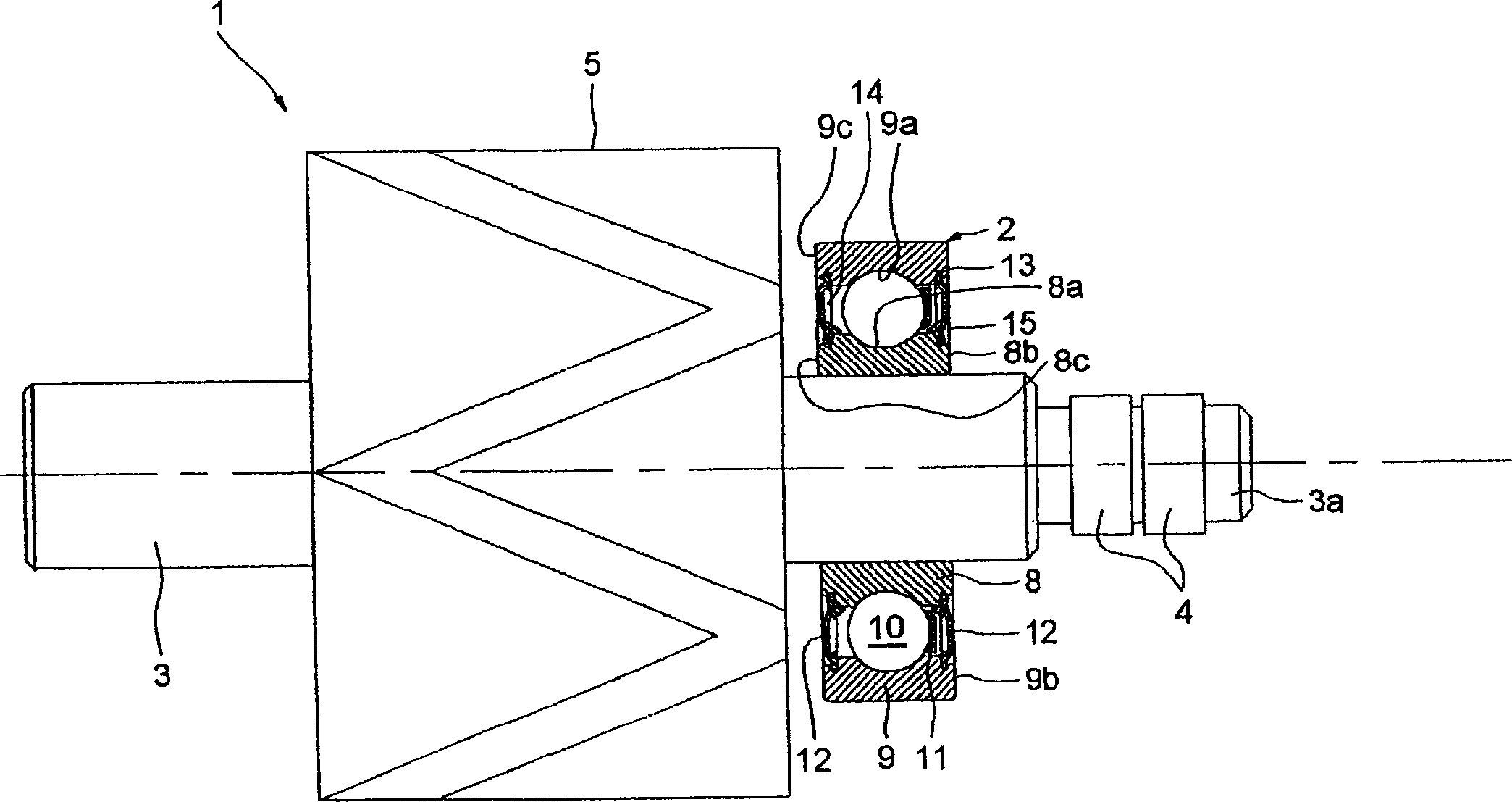

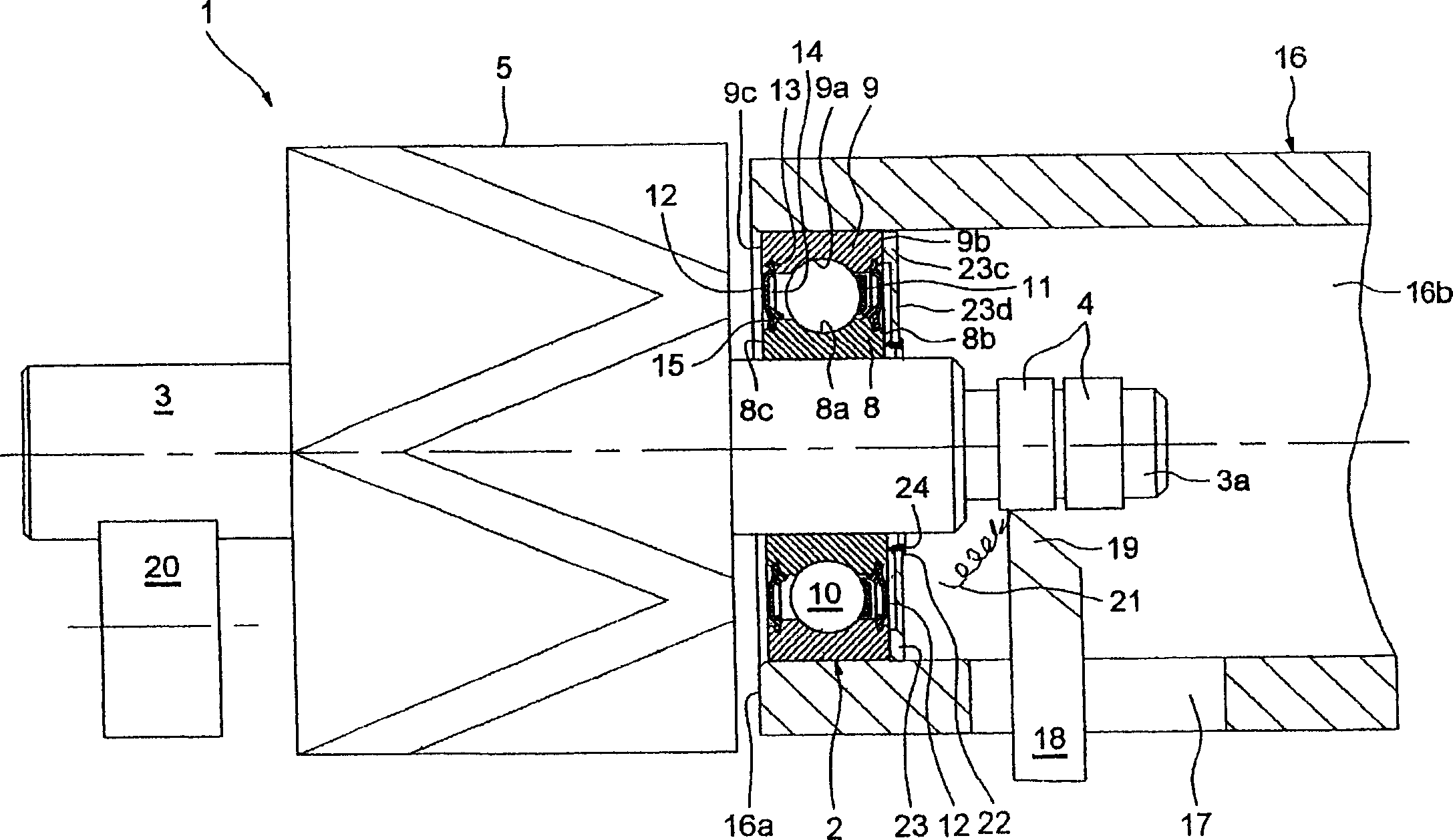

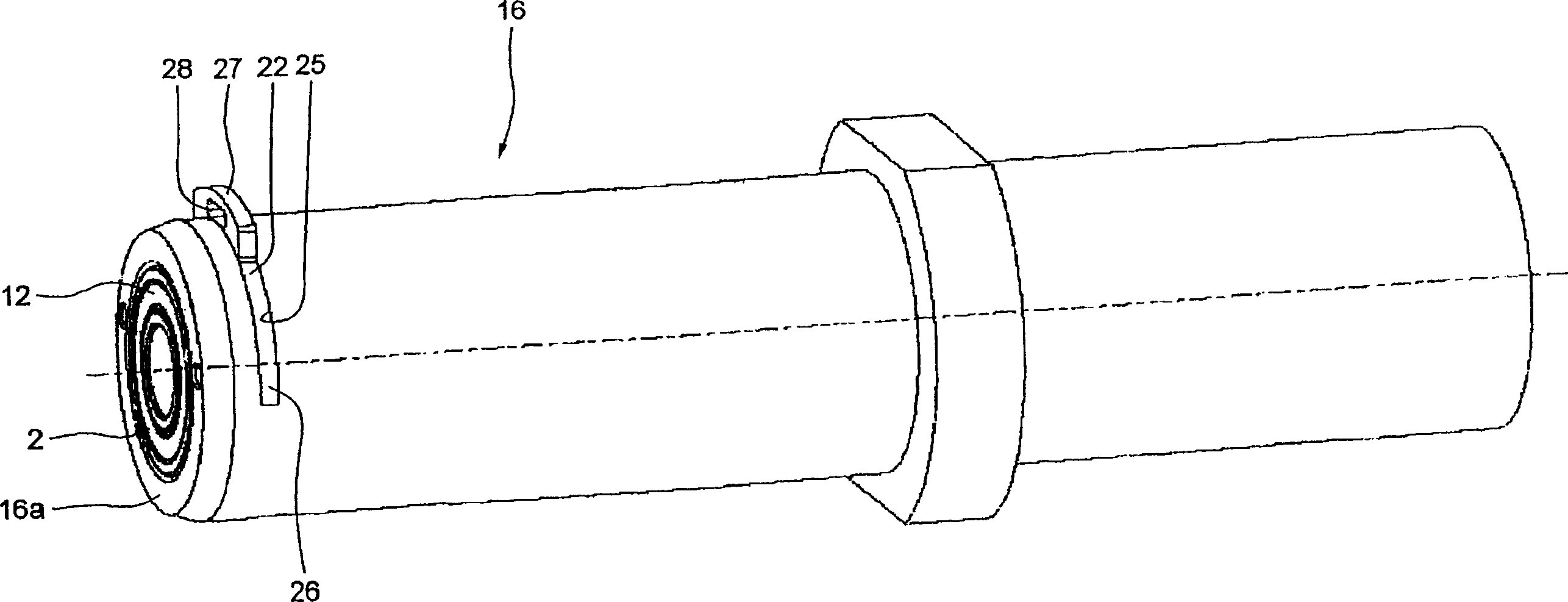

[0037] from figure 1 It can be seen that the rotor 1 is combined with the bearing 2. The rotor 1 includes a shaft 3 having a small-diameter end 3 a that supports a slip ring 4 . The rotor 1 also comprises a body 5 comprising pole pieces and windings. Bearing 2 is mounted on shaft 3 between end 3 a and body 5 . An end of the shaft 3 opposite to the small-diameter end portion 3 a protrudes out of the body portion 5 .

[0038] The bearing 2 includes an inner ring 8 having a hole, an outer ring 9 having a shaft 3, and a row of rolling elements 10, the inner ring 8 being in contact with the shaft 3, and the outer surface of the inner ring having a concave track 8a. Facing outwards and having a hole with a concave track 9a, said rollers 10 being balls in this case, arranged between the tracks 8a and 9a. The tracks 8a and 9b may be formed by machining to remove debris. The bearing 2 additionally comprises a frame 11 made of synthetic material for maintaining a regular circumfere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com